Method for synthesizing fatty acyl amino acid surfactant by using direct method

A fatty acyl amino acid and surfactant technology, applied in the field of surfactant preparation, can solve the problems of insufficient green raw materials, "three wastes" discharge, low yield, etc., and achieve the advantages of improving application convenience, reducing use and emission, Ease of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

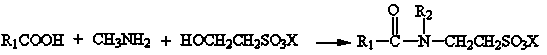

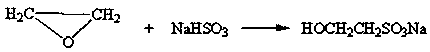

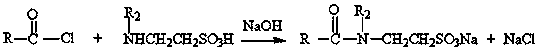

Method used

Image

Examples

Embodiment 1

[0053]The method for the direct synthesis of fatty acyl amino acid surfactant in this embodiment, the steps are as follows:

[0054] Add 0.1mol of coconut oil acid, 0.5mol of methylamine, and 0.12mol of sodium isethionate into the reactor, close the reactor, slowly raise the temperature to 210°C, keep the temperature for 4 hours, and distill off the unreacted methylamine. Add 0.05% hydrochloric acid of reactant weight, adjust the pH value at 6.5~7.5, granulate to obtain light yellow N-cocoyl-N-methyl taurate granules, N-cocoyl-N-methyl taurate The sodium acid content is 90.5%, and the coconut oil content is 2.1%.

Embodiment 2

[0056] The method for the direct synthesis of fatty acyl amino acid surfactant in this embodiment, the steps are as follows:

[0057] Add 0.14mol of cocoic acid, 3mol of methylamine, and 0.1mol of sodium isethionate into the reactor, seal the reactor, slowly raise the temperature to 150°C, keep the temperature for 3 hours, distill off the unreacted methylamine, add Reactant weight 0.1% taurine, adjust the pH value at 6.5 ~ 7.5, add water to adjust the mass percentage to 30%, to obtain light yellow N-cocoyl-N-methyl taurine sodium taurate solution, N- The content of sodium cocoyl-N-methyl taurine taurate is 26.4%, and the content of cocoic acid is 3.1%.

Embodiment 3

[0059] The method for the direct synthesis of fatty acyl amino acid surfactant in this embodiment, the steps are as follows:

[0060] Add 0.2 mol of caprylic acid, 1.0 mol of methylamine, and 0.10 mol of sodium isethionate into the reactor, seal the reactor, slowly raise the temperature to 150°C, keep the temperature for 4 hours, and distill off the unreacted methylamine. Add 0.05% hydrochloric acid of reactant weight, adjust pH value at 6.5~7.5, obtain light yellow N-octyl decanoyl-N-methyl taurate sodium, N-octyl decanoyl N-methyl taurate sodium content 95.6%, caprylic acid content 0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com