Microwave synthesis method of sodium fatty acyloxy isethionate

A technology of sodium fatty acyloxyethylsulfonate and sodium isethionate, which is applied in the fields of sulfonate preparation, chemical instruments and methods, organic chemistry, etc., and can solve the problem of light color of sodium fatty acyloxyethylsulfonate, Phosphorus trichloride irritating environment, low reaction temperature and other problems, to achieve the effect of short reaction time at high temperature, reduced energy consumption, and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 50.0g of sodium isethionate and 92.2g of coconut oleic acid into a special microwave reaction flask, put it into a microwave reactor, connect the vacuum system, temperature measurement system, and stirring system, turn on the microwave and raise the temperature to 190°C and the pressure to 100KPa After keeping the microwave power 150W to react for 30min, pour out and place in a vacuum desiccator to cool and just obtain the finished product sodium cocoyl oxyethyl sulfonate 132.2g.

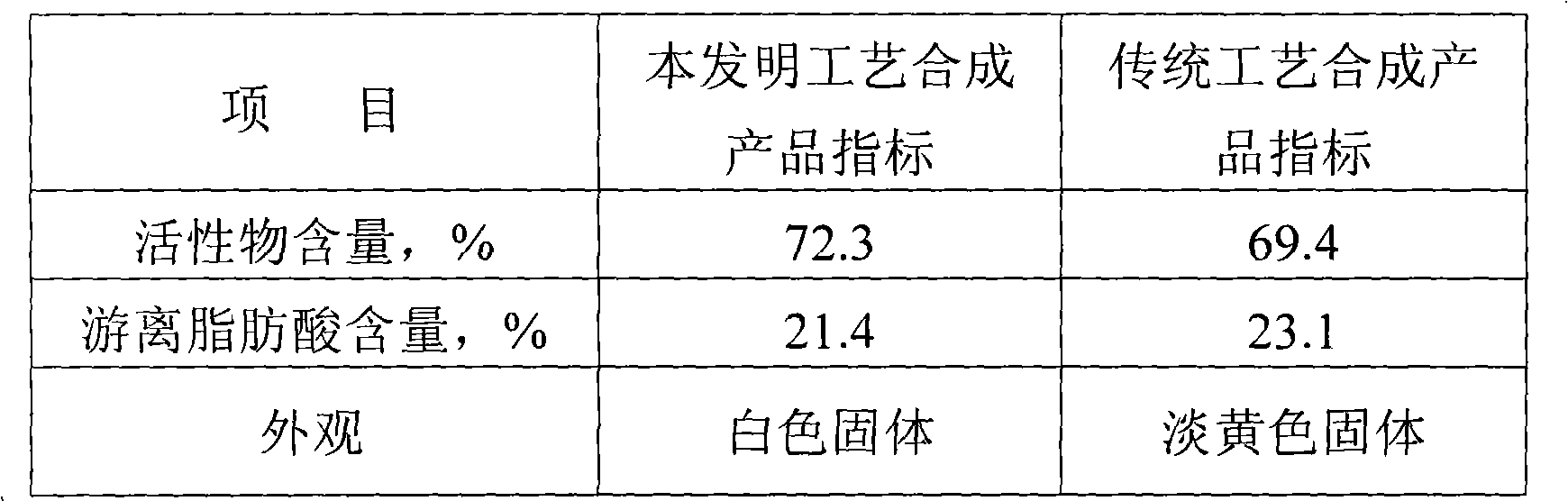

[0024] The resulting quality indicators are as follows:

[0025]

[0026] It can be seen that the product quality obtained by the present invention is obviously better than the traditional technology.

Embodiment 2

[0028] Add 50.0g of sodium isethionate and 87.8g of lauric acid into a special microwave reaction flask, put it into the microwave reactor, connect the temperature measurement system and the stirring system, and pass N 2 Bubbling, the bubbling speed is 70 bubbles / min; turn on the microwave and heat up to 190°C, keep the microwave power at 150W and react for 30 minutes, pour it out and put it in a vacuum desiccator to cool to get the finished sodium laurate acyloxyethylsulfonate 130.2g .

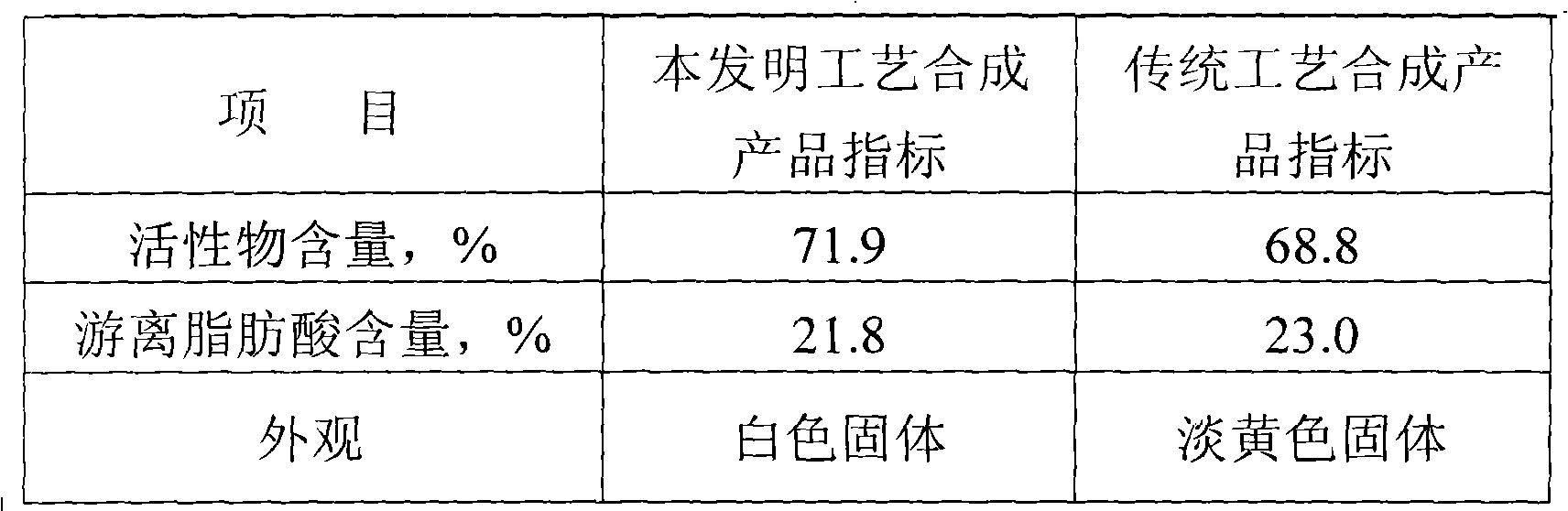

[0029] The resulting quality indicators are as follows:

[0030]

[0031] It can be seen that the product quality obtained by the present invention is obviously better than the traditional technology.

Embodiment 3

[0033] Add 50.0g of sodium isethionate and 100g of myristic acid into a special microwave reaction flask, put it into a microwave reactor, connect a vacuum system, a temperature measurement system, and a stirring system, and turn on the microwave to raise the temperature to 195°C and the pressure to 100KPa; After keeping the microwave power at 150W for 30 minutes, pour it out and place it in a vacuum desiccator to cool to obtain 140 g of the finished sodium myristate acyloxyethylsulfonate.

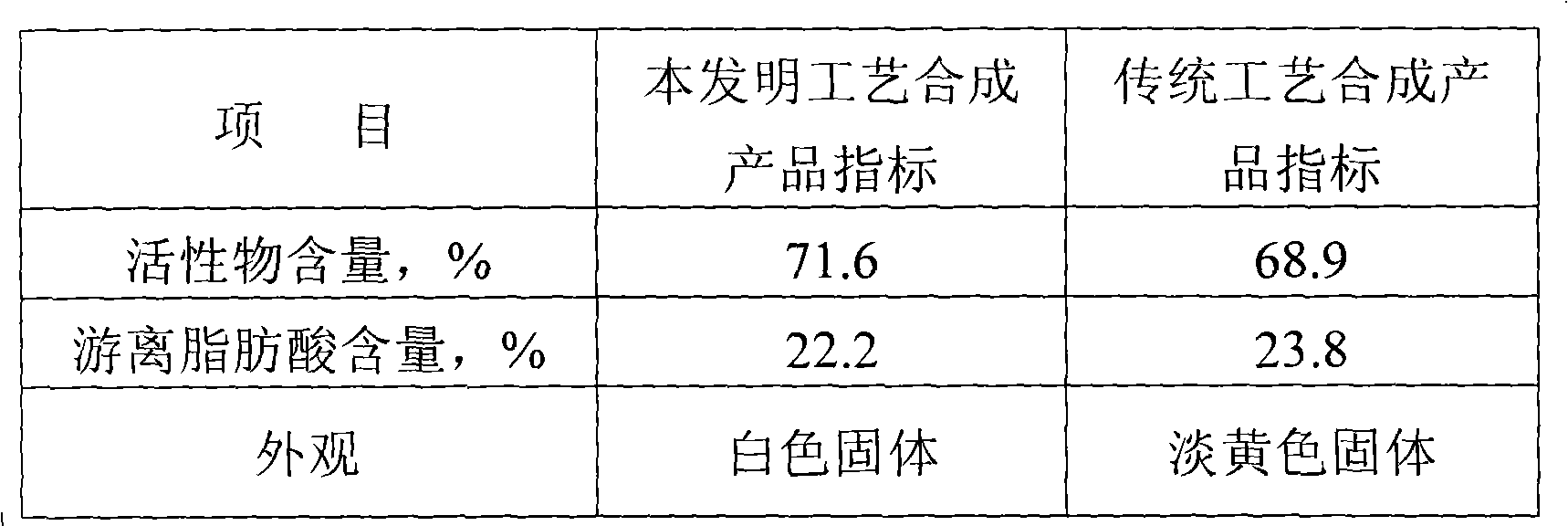

[0034] The resulting quality indicators are as follows:

[0035]

[0036] It can be seen that the product quality obtained by the present invention is obviously better than the traditional technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com