Multilevel drying and cooling integration technics of wet-type ammonia flue gas desulphurization offspring and its system

A cooling process and product technology, which is applied in the field of wet ammonia flue gas desulfurization product treatment, can solve problems such as easy bonding, and achieve the effects of reducing process costs, simplifying heating equipment, and short-term high-efficiency treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

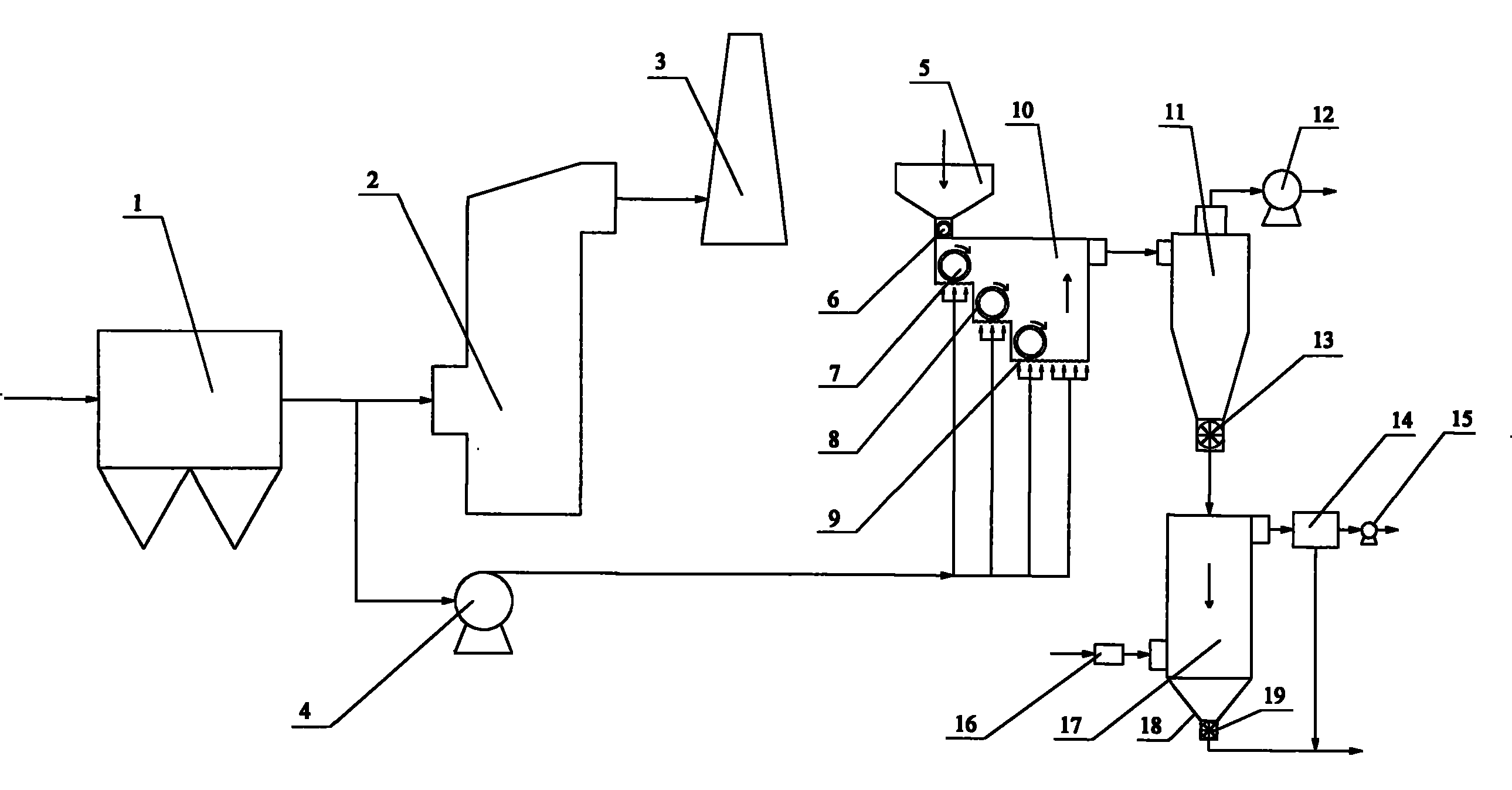

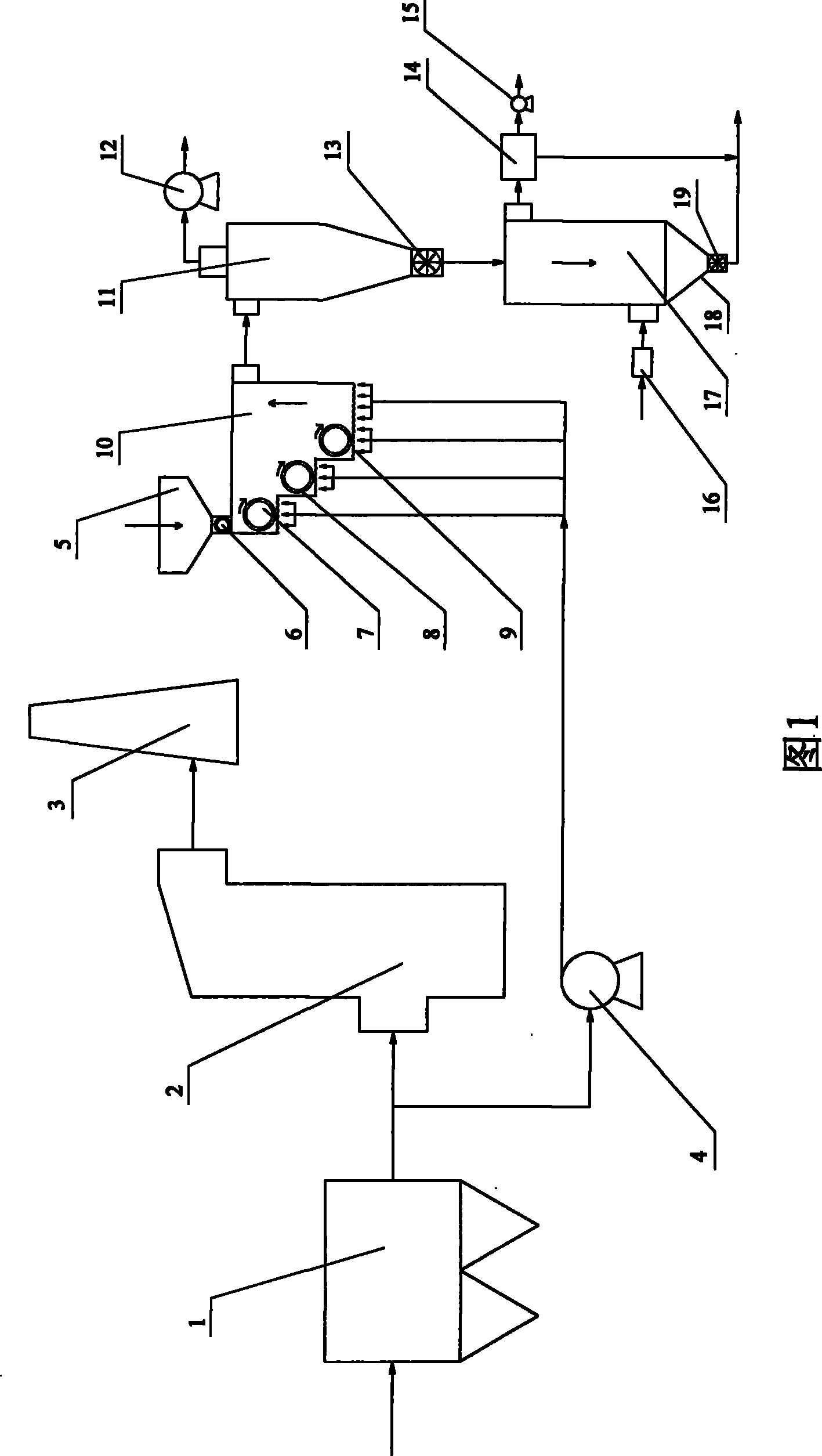

[0027] The multi-stage drying and cooling system for the wet ammonia flue gas desulfurization products shown in the figure is mainly composed of a multi-stage spiral tube drying device, a gas-solid separation device and an air cooling device.

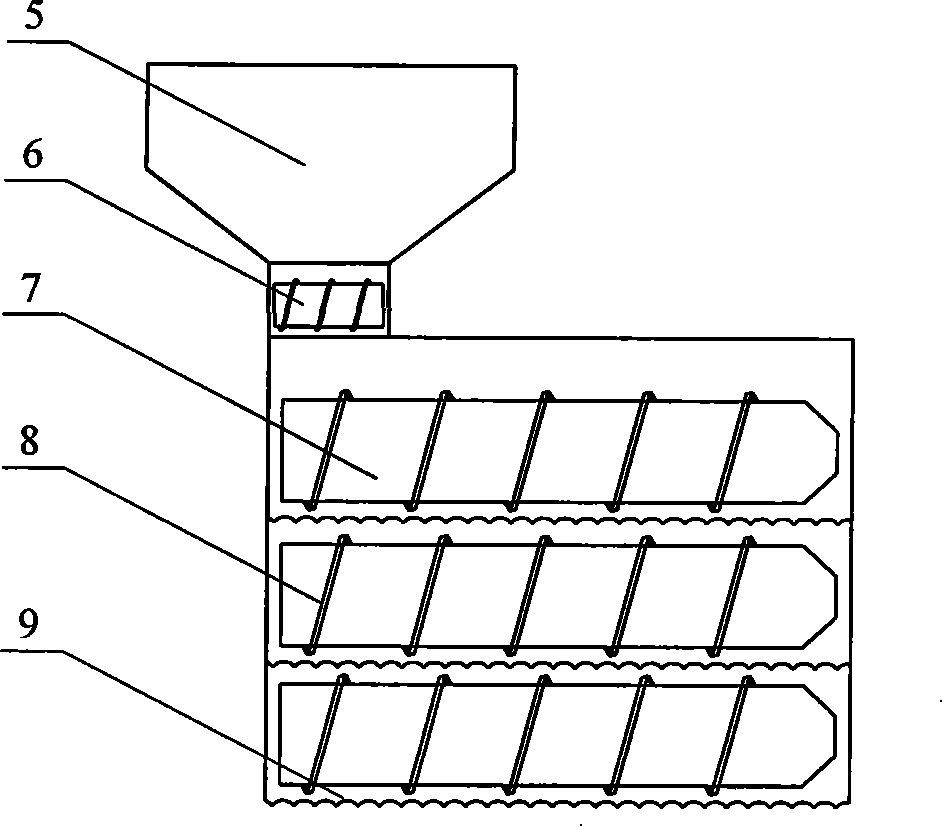

[0028] The multistage spiral tube drying device includes a feed hopper 5 , a screw feeder 6 , a drying device cavity 10 and a multistage spiral tube 7 . The feed hopper 5 is connected to the inlet of the drying device cavity 10 through the screw feeder 6 arranged at the outlet of the bottom thereof. In this embodiment, three spiral drying pipes 7 are arranged in the drying device cavity 10 in a ladder shape, and each screw is dried. The surface of the pipe 7 is provided with a spiral blade 8, and each spiral drying pipe 7 is rotated by a motor, forming a three-stage spiral conveying structure. The feed h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com