Cable -heating device

A cable and electric furnace technology, applied in the field of mechanical mechanism testing, can solve problems such as burning out cables, not easy to control liquid temperature, and signal superposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

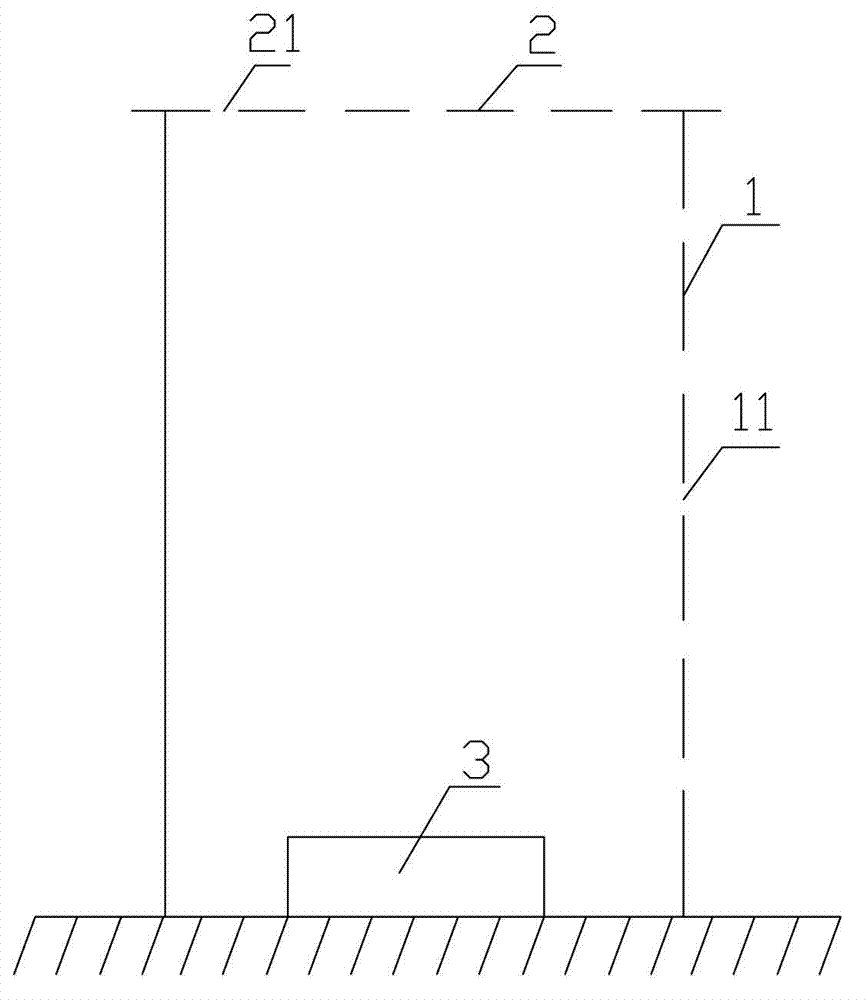

[0009] Such as figure 1 A cable heating device shown includes an iron drum 1, an iron drum lid 2, and an adjustable electric furnace 3, and is characterized in that a row of temperature measuring holes 11 are arranged at intervals and evenly spaced along the height direction on the side wall of the iron drum 1 , in order to ensure that the tested cable is in a horizontal position, the size of each temperature measuring hole 11 needs to be adapted to the diameter of the wound cable, and the tested cable is wound to the corresponding temperature measuring hole 11; the iron drum cover 2 is distributed with temperature The adjustment holes 21 are used to adjust the temperature of the iron drum by adjusting the number of openings of the temperature adjustment holes 21 ; the adjustable electric furnace 3 is arranged at the bottom of the iron drum 1 .

[0010] Except for the technical features described in the instructions, all are known technologies by those skilled in the art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com