A kind of circlip dipping and leveling processing method and circlip

A processing method and circlip technology, which is applied in the direction of connecting components, coatings, pre-treated surfaces, etc., can solve the problems of plastic layer falling off and the inability to guarantee the bonding strength of the plastic layer on the outer layer of the circlip wire, and achieve uniform heating , save the space of the production site, and improve the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

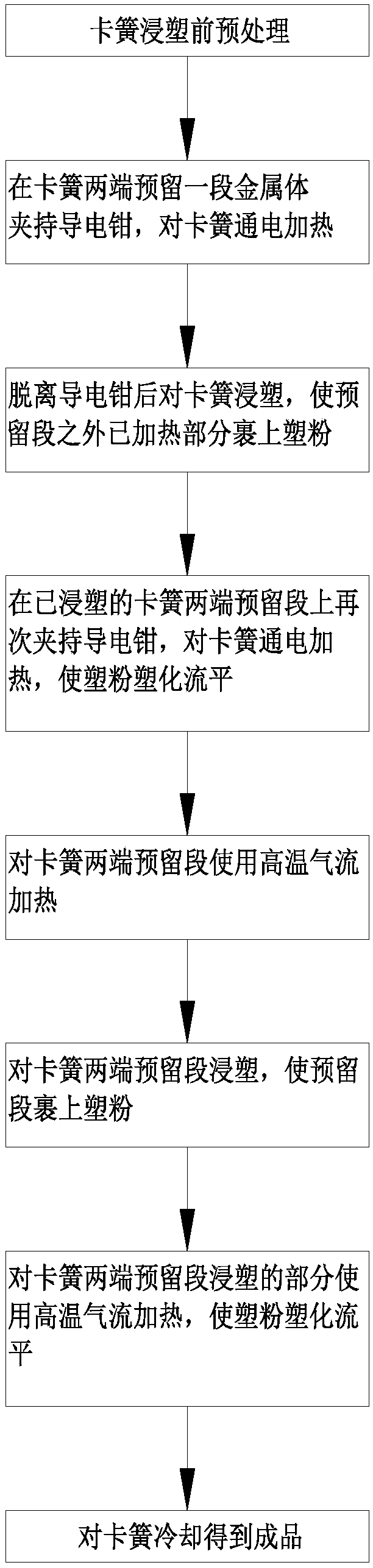

[0038] like figure 1 Shown is one of the embodiments of the present invention, in this embodiment, a method for dipping and leveling the circlip, the method includes the following steps:

[0039] Step 1) Pretreatment before dipping the circlip.

[0040] Step 2) Reserve a section of metal body at both ends of the circlip to clamp the conductive pliers, and energize and heat the circlip; in this step, if the circlip is regarded as a resistance wire, because the reserved section does not constitute a part of the circuit, it is reserved The temperature of the section does not change significantly, and the temperature of other parts of the circlip is not as high.

[0041] Step 3) After detaching from the conductive clamp, dip the circlip in plastic, so that the heated part outside the reserved section is coated with plastic powder. In this step, the circlip can be soaked in the plastic powder pool, or it can be sprayed with powder. Because the temperature of the reserved section ...

Embodiment 2

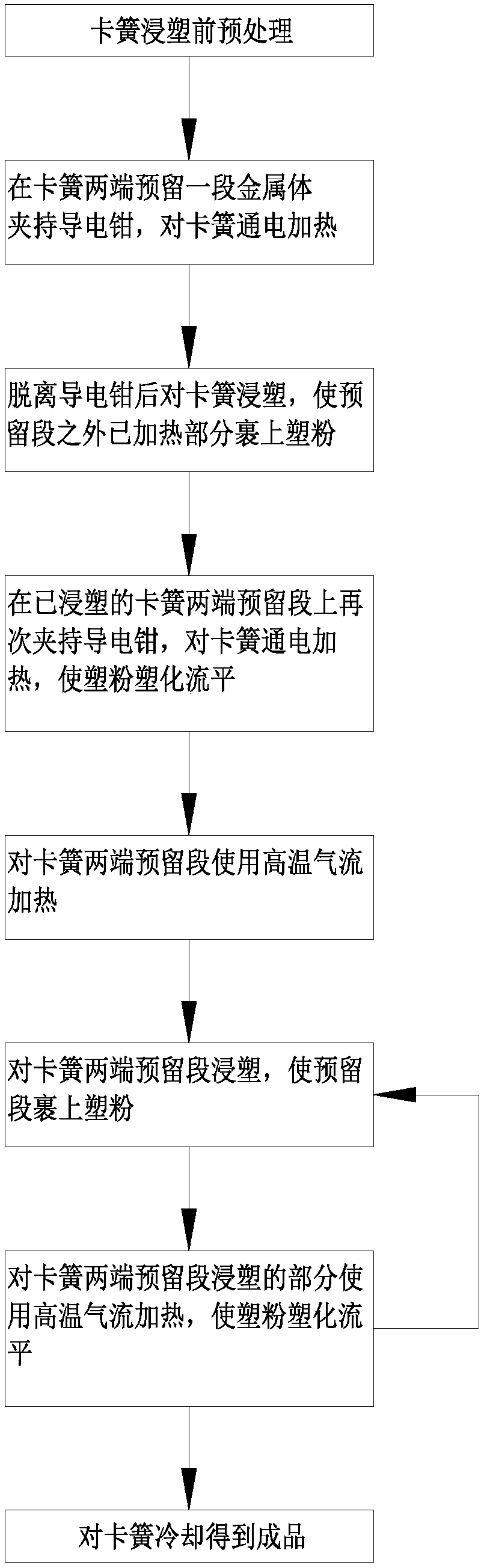

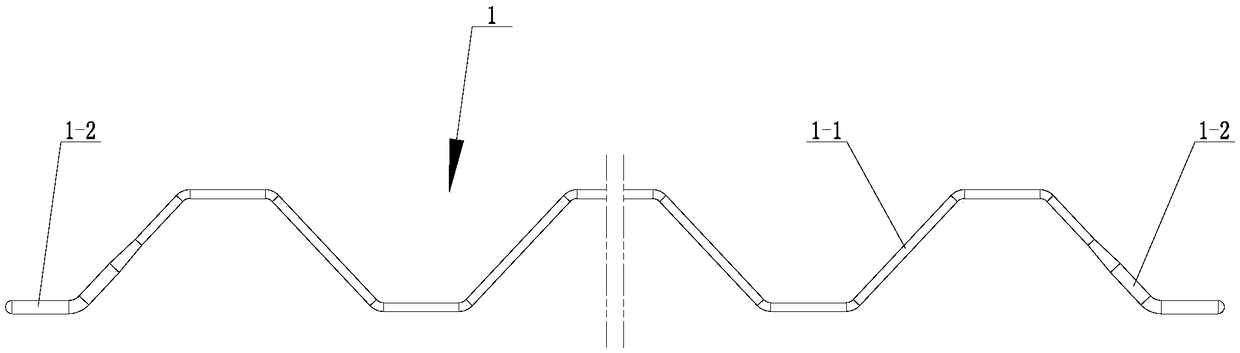

[0057] like figure 2 , image 3 Shown is the second embodiment of the present invention. In this embodiment, step 6) and step 7) in embodiment 1 can be repeated to perform dipping and leveling on the reserved sections at both ends of the circlip several times. Specifically, it can be repeated 1 time, 2 times, or 3 times, etc.

[0058] Through repeated dipping and leveling, the diameter of the reserved section at both ends of the circlip is larger than the diameter of other parts of the circlip, and the thickened layer is composed of a plastic layer. like image 3 As shown in , the thickened segment 1-2 has a larger diameter than the base segment 1-1.

[0059] Thickening the two ends of the circlip can better prevent the circlip from piercing the greenhouse film during use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com