Low-pollution lignin dispersant for disperse dye as well as preparation method and application thereof

A disperse dye and staining technology, which is applied in the field of biomass resource utilization, can solve problems such as fiber staining, achieve the effects of improving adsorption performance, improving dispersion stability, and increasing adsorption strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

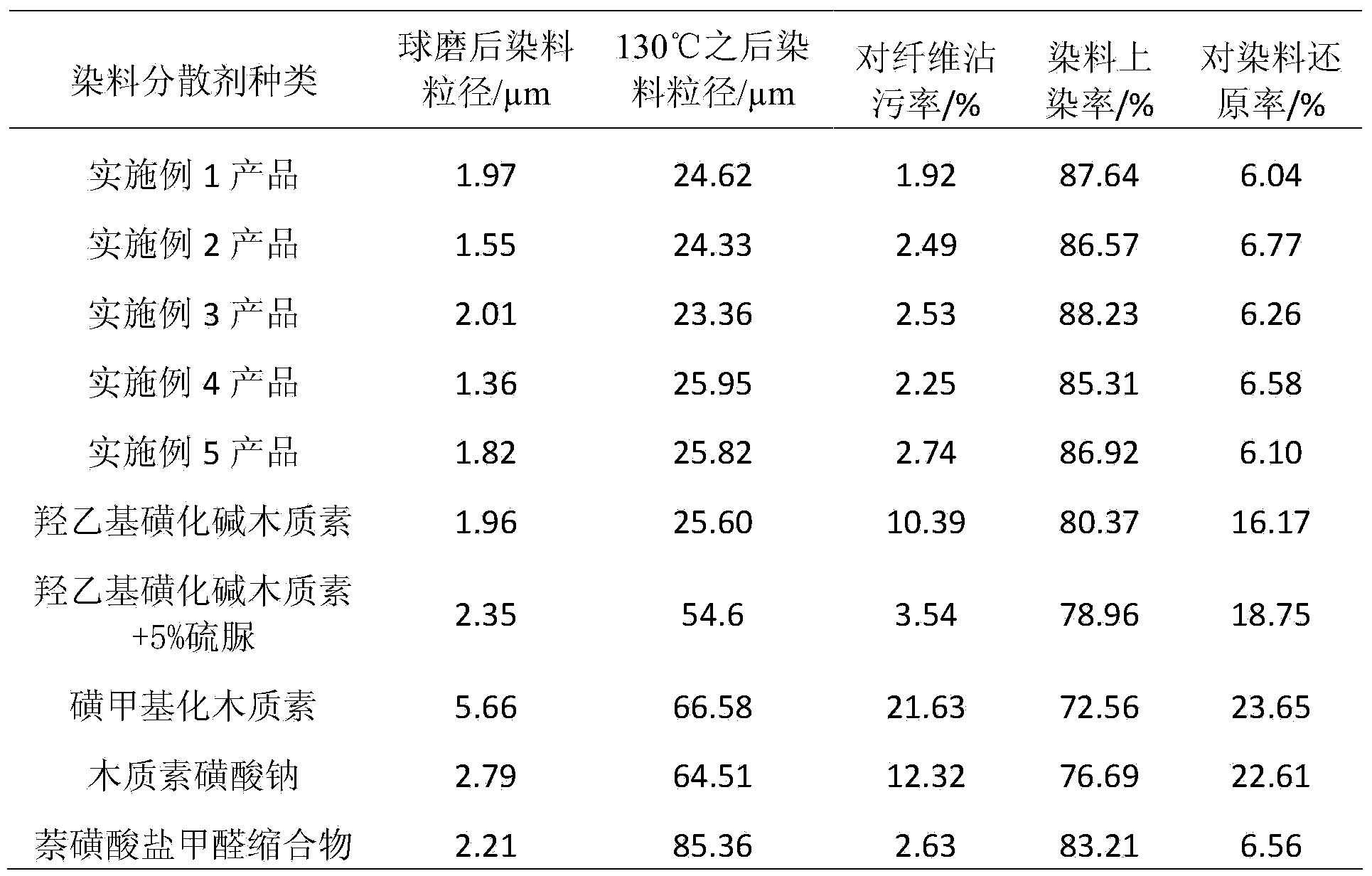

Examples

Embodiment 1

[0035] Take 100g of wood pulp alkali lignin solid and dissolve it in water, adjust the pH to 9.0 with a mass concentration of 20% sodium hydroxide aqueous solution, prepare a wood pulp alkali lignin aqueous solution with a mass concentration of 20%, heat to 60°C, add 5g of hydroxy Sodium ethylsulfonate was reacted for 1h to obtain an isethionated alkali lignin solution;

[0036] Adjust the pH of the isethionated alkali lignin solution to 4.0 with an aqueous sulfuric acid solution with a mass concentration of 10%, add 2g of hydroxyethylurea and 1g of n-octanol, and stir at 40°C for 60min to obtain a low-sticking agent for disperse dyes. Sludge lignin-based dispersant liquid product.

Embodiment 2

[0038] Get 100g of bamboo pulp alkali lignin solid and dissolve it in water, adjust the pH to 12.0 with a mass concentration of 30% potassium hydroxide aqueous solution, prepare a bamboo pulp alkali lignin aqueous solution with a mass concentration of 50%, heat to 90°C, add 30g of hydroxy Sodium ethylsulfonate was reacted for 3 hours to obtain an isethionated alkali lignin solution;

[0039] Adjust the pH of the isethionated alkali lignin solution to 6.0 with 20% aqueous sulfuric acid, add 10 g of guanidine hydrochloride and 5 g of dodecanol, and stir at 80° C. for 90 min to obtain a lignin-based dispersant liquid product.

Embodiment 3

[0041] Take 30g of bagasse alkali lignin and 70g of wood pulp alkali lignin solid and dissolve them in water, adjust the pH to 10.0 with a 25% aqueous solution of sodium hydroxide, prepare an aqueous solution with a mass concentration of 25%, heat to 80°C, and add 20g Sodium isethionate, reacted for 2 hours to obtain isethionated alkali lignin solution;

[0042] Use 15% sulfuric acid aqueous solution to adjust the pH of isethionated alkali lignin solution to 5.0, add 2.5g hydroxyethylurea and 5g semicarbazide, 1g dodecanol and 2g n-nonanol, stir at 70°C for 75min, thus obtain Lignin-based dispersant liquid product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com