Matched silicon-carbon anode lithium-ion battery electrolyte and silicon-carbon anode lithium-ion battery

A lithium-ion battery and electrolyte technology, which is applied in the field of matching silicon-carbon negative electrode lithium-ion battery electrolyte and silicon-carbon negative electrode lithium-ion battery, can solve the problem of poor long-life cycle performance, large change in volume expansion and internal resistance, and poor battery performance. and other problems, to achieve the effect of inhibiting battery gas production, improving thermal stability, and improving high-temperature storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

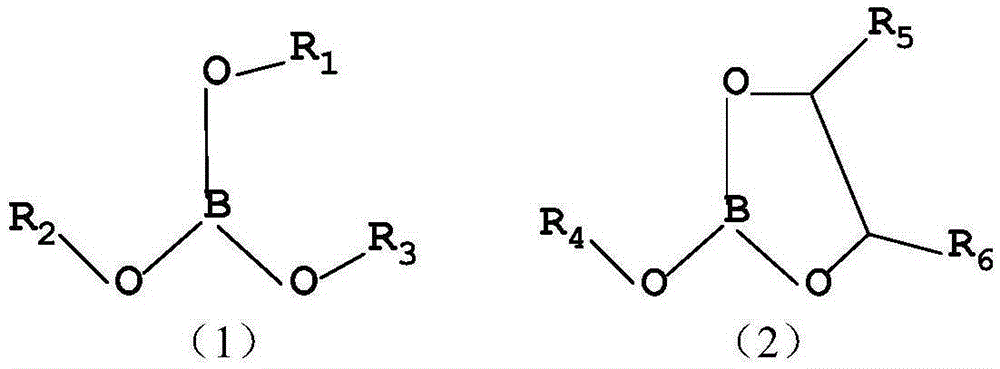

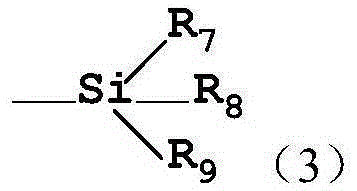

Method used

Image

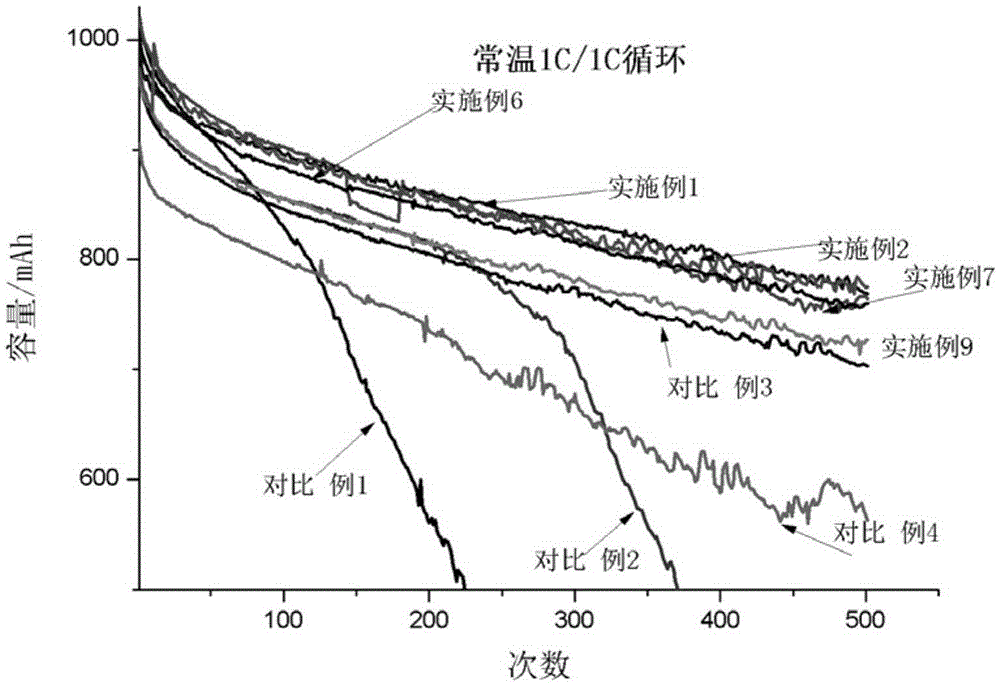

Examples

Embodiment 1

[0043] In a glove box filled with argon (moisture 6 , and stirred until it was completely dissolved to obtain the lithium-ion battery electrolyte of Example 1.

[0044] The lithium-ion battery electrolyte prepared above is injected into the positive electrode active material as lithium cobaltate LiCoO 2 , in the soft pack lithium-ion battery whose negative electrode active material is the silicon carbon negative electrode (silicon content in the silicon carbon negative electrode material accounts for 1% to 30%), the battery after liquid injection is packaged, shelved, formed, aged, secondary packaged, capacity separation and other processes to obtain a silicon-carbon negative electrode lithium-ion battery.

Embodiment 2

[0046] In a glove box filled with argon (moisture 6 , and stirred until it was completely dissolved to obtain the lithium-ion battery electrolyte of Example 2.

[0047] The lithium-ion battery electrolyte prepared above is injected into the positive electrode active material as lithium cobaltate LiCoO 2 , in the soft pack lithium-ion battery whose negative electrode active material is the silicon carbon negative electrode (silicon content in the silicon carbon negative electrode material accounts for 1% to 30%), the battery after liquid injection is packaged, shelved, formed, aged, secondary packaged, capacity separation and other processes to obtain a silicon-carbon negative electrode lithium-ion battery.

Embodiment 3

[0049] In a glove box filled with argon (moisture 6 , and stirred until it was completely dissolved to obtain the lithium-ion battery electrolyte of Example 3.

[0050] The lithium-ion battery electrolyte prepared above is injected into the positive electrode active material as lithium cobaltate LiCoO 2 , in the soft pack lithium-ion battery whose negative electrode active material is the silicon carbon negative electrode (silicon content in the silicon carbon negative electrode material accounts for 1% to 30%), the battery after liquid injection is packaged, shelved, formed, aged, secondary packaged, capacity separation and other processes to obtain a silicon-carbon negative electrode lithium-ion battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com