Light-calcined magnesia calcining furnace desulfurization technique and system

A technology for lightly burning magnesia and desulfurization process is applied in the field of desulfurization process and its system, which can solve the problems of high price, low profit, secondary pollution and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

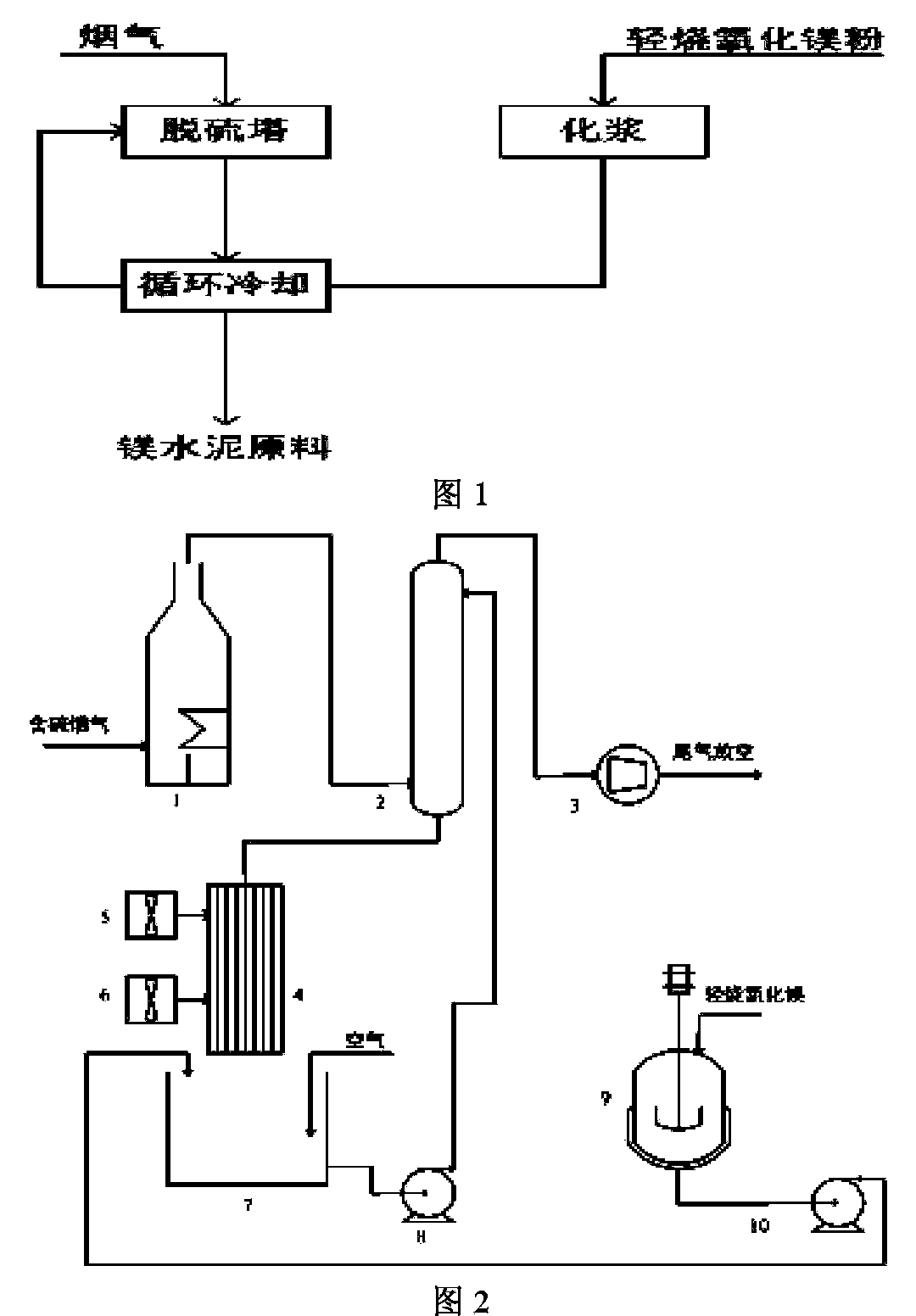

Method used

Image

Examples

Embodiment 1

[0023] In the light calcined powder calciner 1 with coal gas as the heat source, 50~120 mm massive magnesite (its composition includes: MgCO 3 82.38%, CaCO 3 8.81%, which is lower-grade magnesite) from the top of the furnace, and the high-temperature calcination temperature is 950-1100°C to obtain highly active light-burned powder. The exhaust gas content (volume content %) is: N 2 , 58.9%; CO 2 , 31.8%; O 2 , 1%; SO 2 , 0.2%; Ar, 495ppm; H 2 O, 8.2%. The output of the calciner is 3333 kg / h, of which the desulfurization requires lightly burned powder per hour is 50 kg / h, the solid content of the slurry is 25%, and the amount of slurry is 200 kg / h. SO in flue gas after flue gas desulfurization 2 The flow rate is 45ppm, the desulfurization liquid circulation volume is 30 m3 / h, 45°C, the flue gas temperature rises to 61°C after desulfurization, and about 3% of the water turns into steam. After recycling, the content of magnesium sulfate reaches 250 g / L, and the content o...

Embodiment 2

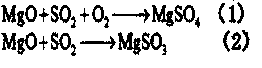

[0025] A system for realizing the desulfurization process of the above-mentioned light-burned magnesia calciner, the system includes 1. light-burned powder calciner; 2. desulfurization tower; 3. tail gas fan; 4. fin heat exchanger; 5. axial flow Fan; 6, axial flow fan; 7, circulation tank; 8, circulation pump; 9, slurry tank; 10, slurry pump, and the light calcined powder calciner 1 is connected to the bottom entrance of the desulfurization tower 2, desulfurization The gas outlet of the tower is connected to the inlet of the tail gas fan, the liquid outlet of the desulfurization tower 2 is connected to the inlet of the fin heat exchanger 4, the outlet of the fin heat exchanger 4 is connected to the top of the circulation tank, and the axial fans 5 and 6 cool the fins for heat exchange device, the outlet of the pulping tank 9 is connected to the inlet of the pulping pump 10, and the inlet of the pulping pump is connected to the inlet of the circulation tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com