Method and device for preparing high-purity high-density magnesia by utilizing magnesite

A high-density, magnesite technology, applied in the field of comprehensive utilization of non-metallic resources, can solve the problems of environmental threats, high raw material cost and processing cost, strong corrosiveness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

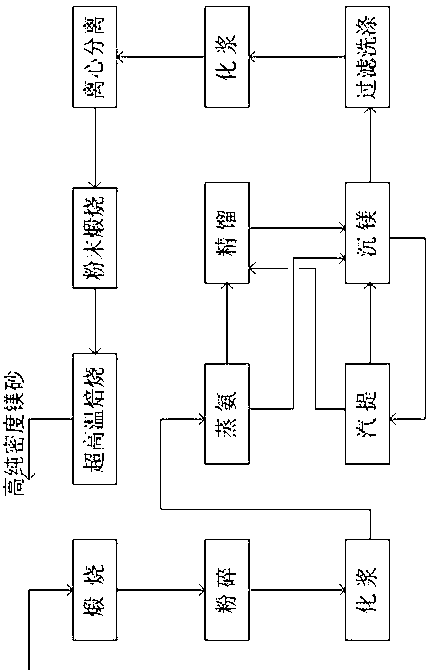

Method used

Image

Examples

Embodiment 1

[0041] Example 1: In a lightly burned powder calciner 1 using coal gas as a heat source, 50-120 mm massive magnesite (its composition includes: MgCO 3 82.38%, CaCO 3 8.81%, which is lower-grade magnesite) from the top of the furnace, and the high-temperature calcination temperature is 950~1100°C to obtain highly active lightly burned powder, of which the MgO content in lightly burned powder is 80%. Put the obtained lightly burned powder into the Raymond Mill 2 for crushing and grinding to obtain lightly burned powder with an average particle size of 200 mesh or more. Weigh 1000 kg of lightly burnt powder, add 3 m 3 In the water, the slurry is melted in the lightly burned pulverized slurry tank 3 to form a slurry with a solid content of 33%, which is added to the slurry metering tank 5 with the slurry pump 4 for metering. Then still use the lightly burned pulverized slurry tank 3 to dissolve 1700 kg of ammonium chloride to 8.5 m 3 In the water, a 200 g / L ammonium chloride ...

Embodiment 2

[0042] Example 2: The feed liquid after ammonia distillation is filtered through a centrifuge 8, wherein the water content of the filter cake after treatment is 30%, and the filter cake has a weight of 520 kg, wherein the filter cake contains MgO, CaCO 3 , MgCl 2 It is used as an excellent raw material for magnesium cement building materials. The liquid is mainly magnesium chloride solution with a concentration of 200 g / L and a volume of 7.4m 3 , into the magnesium chloride metering tank 11; after the gas coming out from the top of the ammonia rectification tower 13 enters into the ammonia rectification tower condenser 15 to condense, a part returns to the ammonia rectification tower as tower top reflux, and a part enters into the ammonia water metering Tank 16, in which the concentration of ammonia reaches 25%, has a volume of 3 m 3 (The amount of this part of ammonia is inconsistent with the amount of ammonia in the above-mentioned ammonia distillation tower because the re...

Embodiment 5

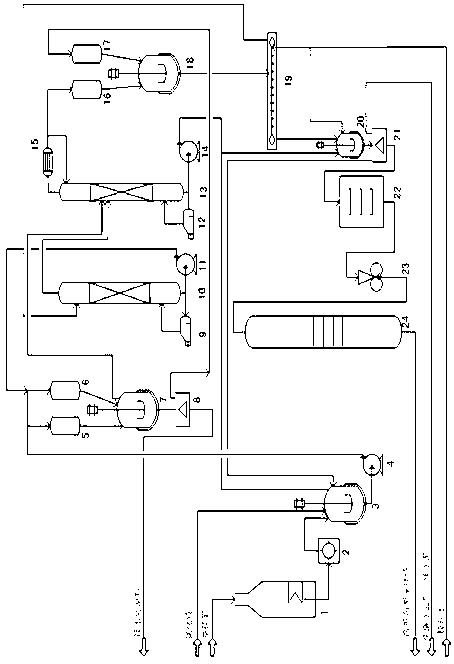

[0045] Embodiment 5: as attached figure 2 As shown, the device for preparing high-purity and high-density magnesite by using magnesite includes 1, light-burned powder calciner; 2, Raymond mill; 3, light-burned powder slurry tank; 4, slurry pump; 5, slurry 6. Ammonium chloride metering tank; 7. Ammonia still; 8. Centrifugal filter; 9. Ammonia stripper reboiler; 10. Ammonia stripper; 11. Stripper discharge pump; 12. Ammonia rectification tower reboiler; 13. Ammonia rectification tower; 14. Rectification tower discharge pump; 15. Ammonia rectification tower condenser; 16. Ammonia water metering tank; 17. Magnesium chloride metering tank; 18. Hydrogen Magnesium oxide preparation kettle; 19, belt vacuum filter; 20, slurry washing kettle; 21, centrifugal filter; 22, drying calciner; 23, ball press machine; 24, ultra-high temperature roasting kiln, and Light-burned powder calciner 1 is connected to the inlet of Raymond mill 2, and the outlet of Raymond mill 2 is connected to the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com