A cleaning process and system for the disposal of acetylene waste acid

An acetylene and clean technology, which is applied in the field of three-waste recycling technology in the PVC industry, can solve problems such as non-compliance with environmental protection requirements, corrosion, and difficulty in selling gypsum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

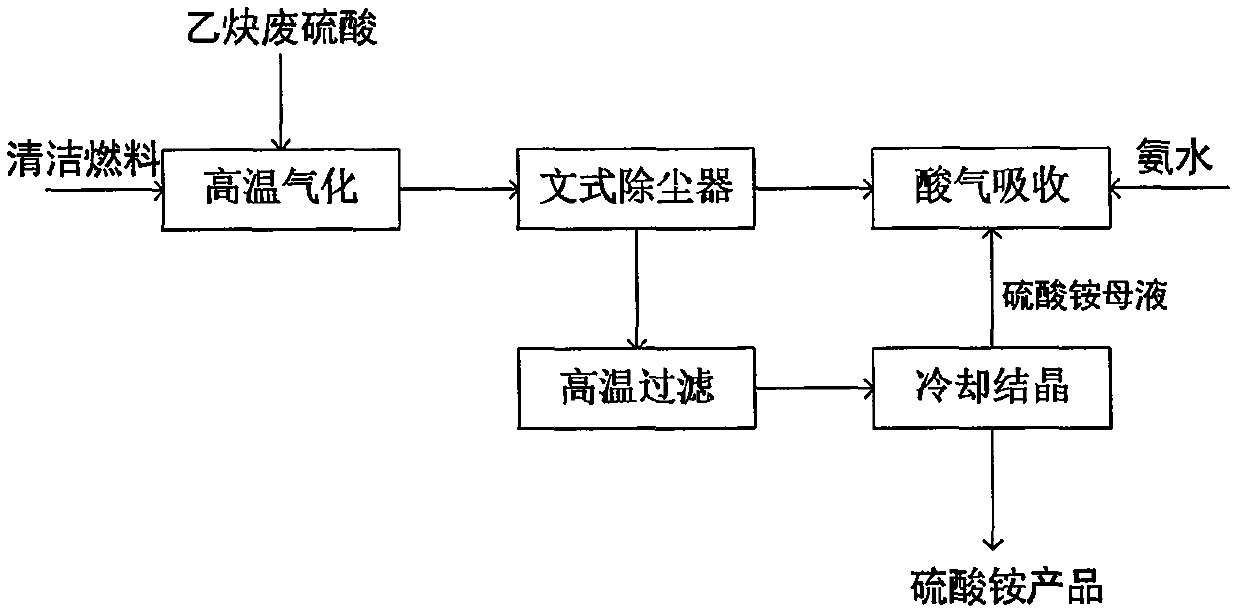

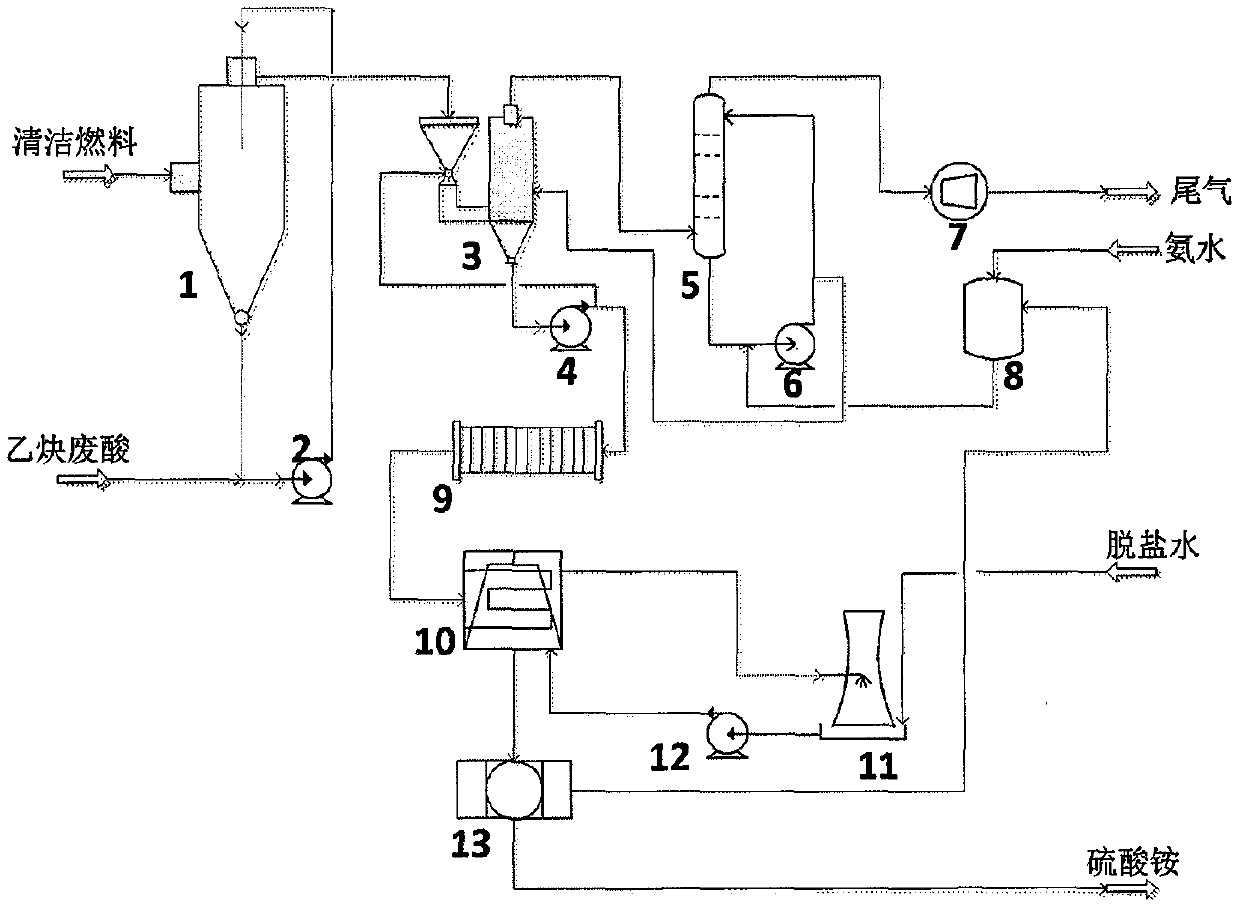

Method used

Image

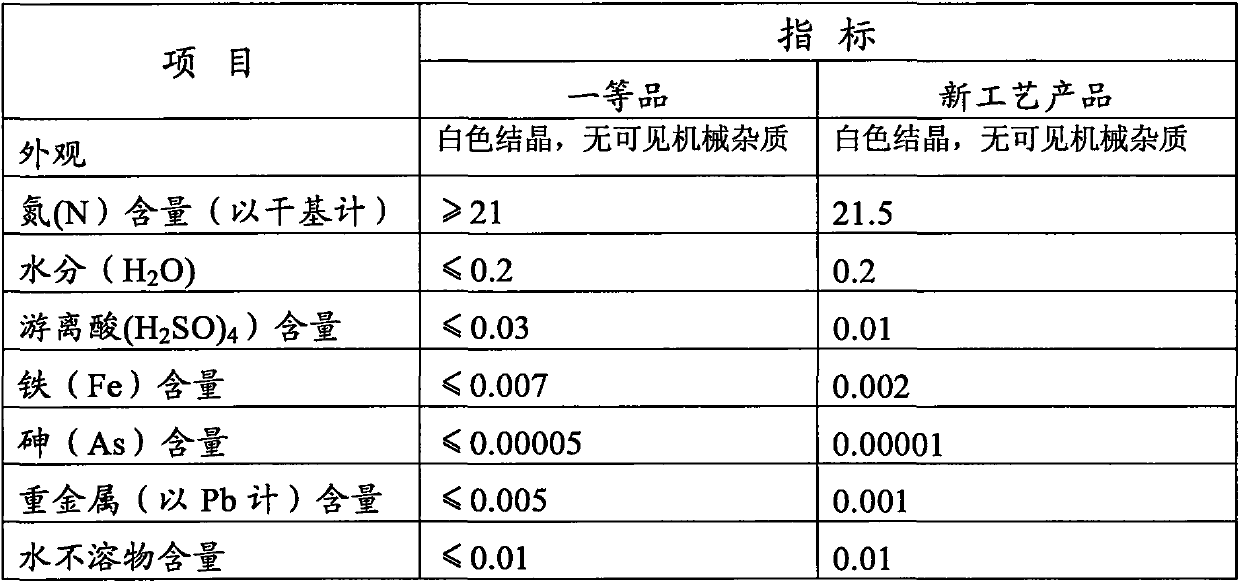

Examples

Embodiment 1

[0030] The design capacity of the device is: annual treatment of waste sulfuric acid is 5000t, and it is approved according to 300 days.

[0031]In the high-temperature gasification furnace (1) using natural gas as a heat source, 2.78t / h of acetylene waste acid (content: 81% sulfuric acid, 2.87% ash content, density: 1.72kg / L) is injected from the top, and the furnace top temperature is 400 °C, furnace bottom temperature is 700 °C, 25% of the liquid after the reaction is vaporized and decomposed into gas, of which SO 3 +H 2 The total amount of O is 0.695t / h (excluding H produced by fuel 2 O) wherein the gas content:

[0032] composition SO 3

h 2 o

N 2

O 2

CO 2

Content (volume content) 0.073 0.19 0.63 0.053 0.054

[0033] The gas leaving the gasifier enters the Venturi precipitator. The composition of the gas leaving the Venturi dust collector is:

[0034] composition SO 3

h 2 o

N 2

O 2

CO 2 ...

Embodiment 2

[0040] The design capacity of the device is: annual treatment of waste sulfuric acid is 5000t, and it is approved according to 300 days.

[0041] In the high-temperature gasification furnace (1) using natural gas as a heat source, acetylene waste acid (content: 81% sulfuric acid, 2.87% ash, density: 1.72kg / L) 2.78t / h is sprayed from the top, and the furnace top temperature is 450 ℃, the furnace bottom temperature is 750℃, 30% of the liquid after the reaction is gasified and decomposed into gas, among which SO 3 +H 2 The total amount of O is 0.834t / h (excluding H produced by fuel 2 O) wherein the gas content:

[0042] composition SO 3

h 2 o

N 2

O 2

CO 2

Content (volume content) 0.083 0.20 0.61 0.053 0.054

[0043] The gas leaving the gasifier enters the Venturi precipitator. The composition of the gas leaving the Venturi dust collector is:

[0044] composition SO 3

h 2 o

N 2

O 2

CO 2

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com