A kind of production technology that utilizes alkylation waste acid to produce sulfate

A technology of alkylation waste acid and production process, applied in the direction of alkali metal sulfite/sulfite, magnesium sulfate, inorganic chemistry, etc., can solve the problems of alkylation waste acid and waste alkali pollution, and achieve good economy Effects of benefits and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

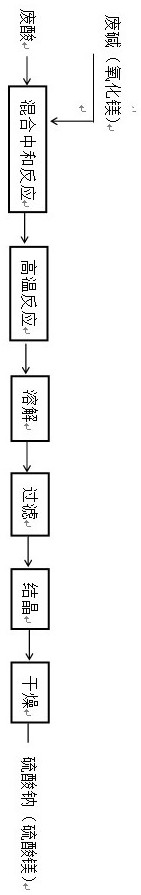

[0028] A kind of production technology that utilizes alkylation waste acid to produce sodium sulfate, consists of the following steps:

[0029] (1) Mixed neutralization reaction: Measure the alkylation waste acid and waste alkali through the metering tank and then add it to the reactor for neutralization reaction, and control the reaction temperature to 90-95°C by circulating water cooling, and then adjust it with caustic soda pH to neutral;

[0030] (2) High-temperature reaction: Add the neutralized product to a high-temperature reactor for high-temperature reaction at 800°C, in which organic matter is decomposed into carbon dioxide and water, and the sulfur dioxide decomposed by excess waste acid in the high-temperature reaction passes through two-stage desulfurization The desulfurization treatment is carried out in the tower, and the desulfurization agent for the desulfurization treatment is caustic soda. The high temperature reactor is under negative pressure conditions du...

Embodiment 2

[0035] A kind of production technology that utilizes alkylation waste acid to produce magnesium sulfate is characterized in that, is made up of following steps:

[0036] (1) Mixed neutralization reaction: Measure the alkylated waste acid and light-burned magnesia through a metering tank (off the scale) and add them to the reactor for neutralization reaction, and control the reaction temperature by circulating water to 90-95 ℃, then adjust the pH value to neutral with caustic soda;

[0037] (2) High-temperature reaction: Add the neutralized product to a high-temperature reactor for high-temperature reaction at 800°C, in which organic matter is decomposed into carbon dioxide and water, and excess waste acid and sulfur dioxide decomposed from magnesium sulfate in the high-temperature reaction Desulfurization treatment is carried out through two-stage desulfurization towers. The desulfurization agent for desulfurization treatment is light-burned magnesium oxide. The high-temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com