Improved process of preparing potassium sulfate with bittern containing potassium and magnesium sulfite

A magnesium sulfate isoform, potassium sulfate technology, applied in the directions of alkali metal sulfite/sulfite, chemical instruments and methods, alkali metal compounds, etc., can solve the problem of large process water consumption, the quality of potassium sulfate cannot be guaranteed, Problems such as low comprehensive recovery rate of ions, etc., to achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

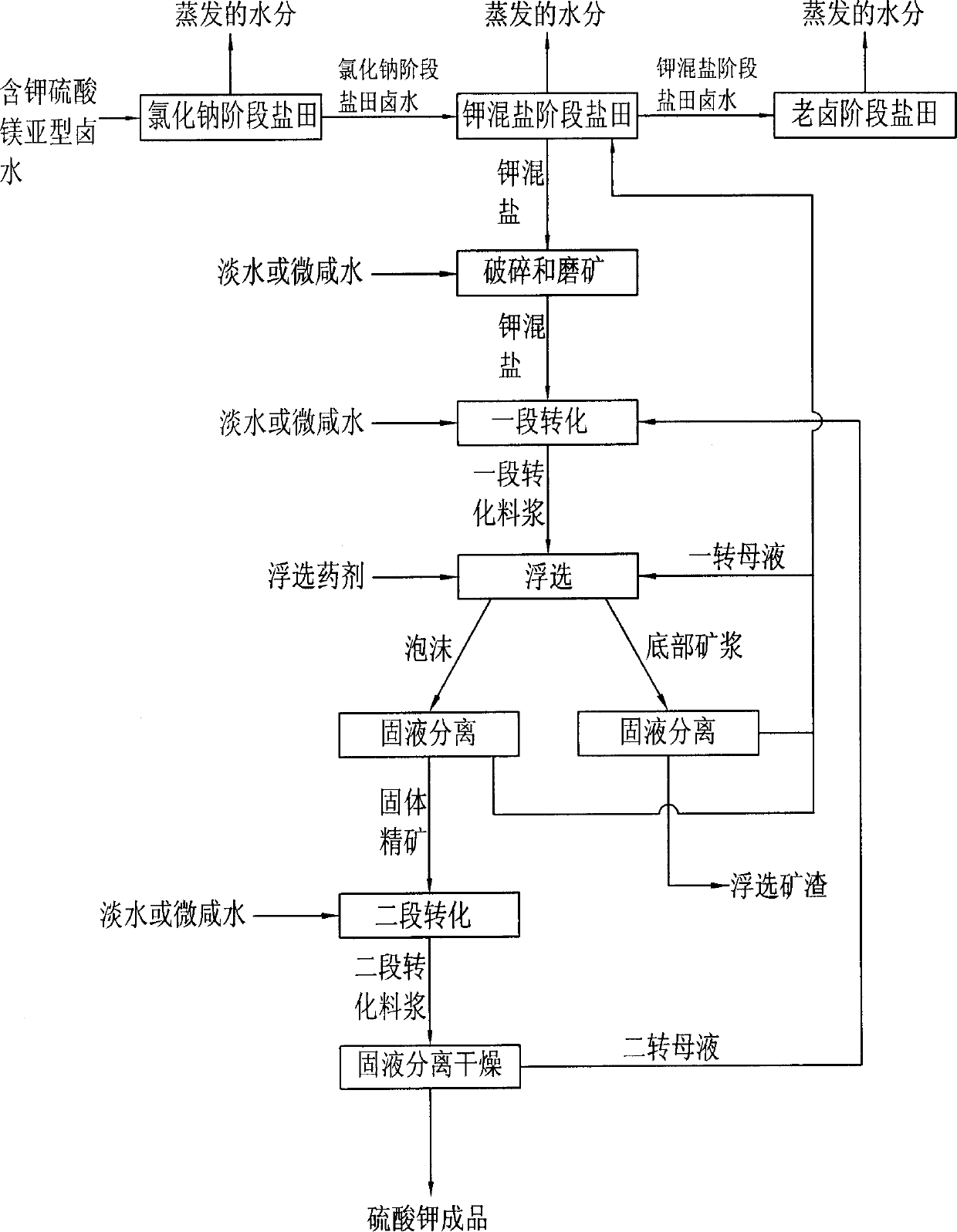

[0034] An improved method for preparing potassium sulfate with potassium-containing magnesium sulfate subtype brine, comprising the following steps:

[0035] ①Inject the potassium-containing magnesium sulfate subtype brine into the salt field in the sodium chloride stage and dry it on the natural beach to meet the brine injection standard in the salt field in the potassium mixed salt stage. After the salt field brine in the sodium chloride stage, inject the salt field brine in the sodium chloride stage into the potassium mixed salt After the natural beach in the stage salt field is sun-dried to meet the brine discharge standard of the potash-mixed salt stage salt field, inject the potassium-mixed salt stage salt field brine into the old brine stage salt field;

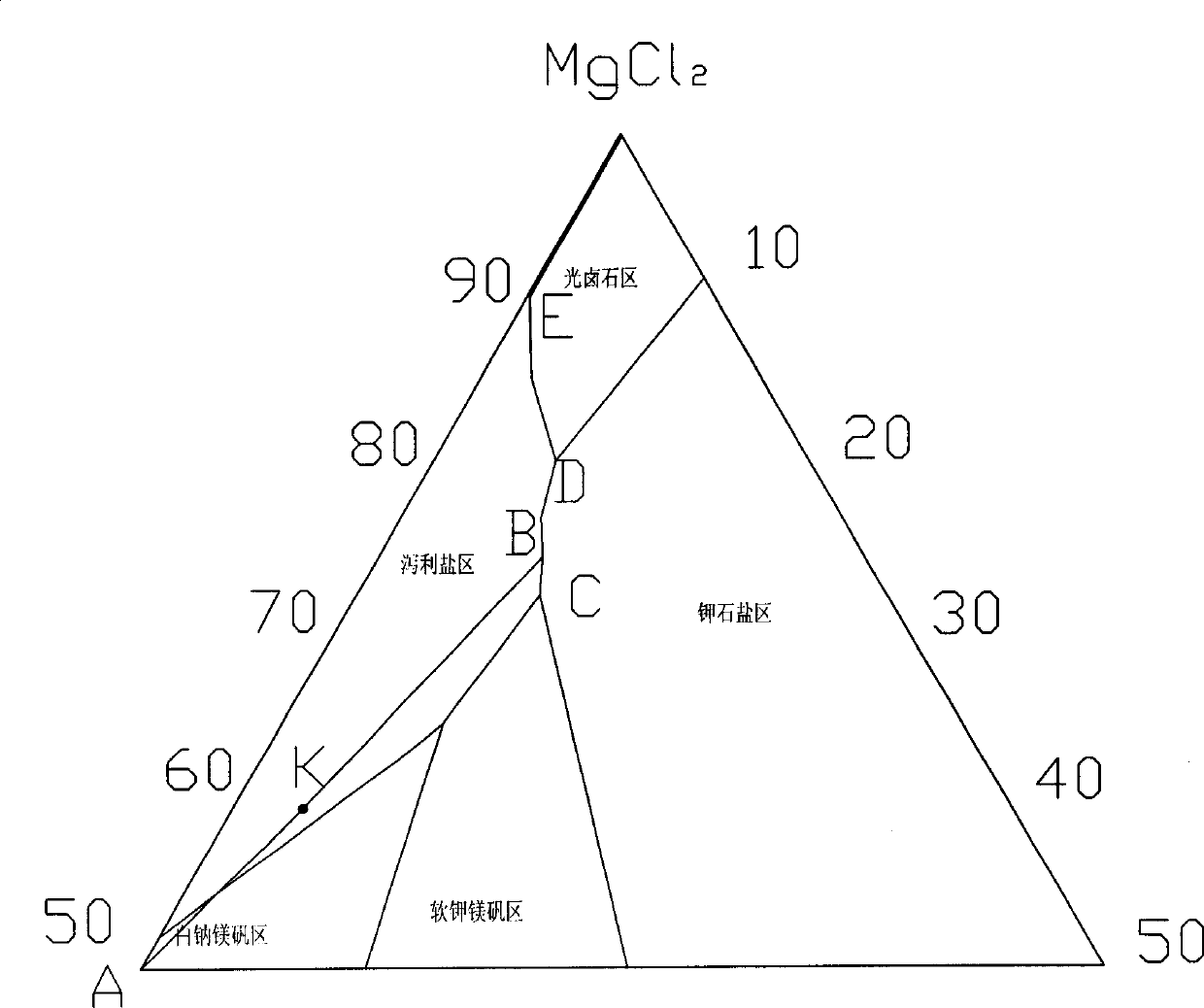

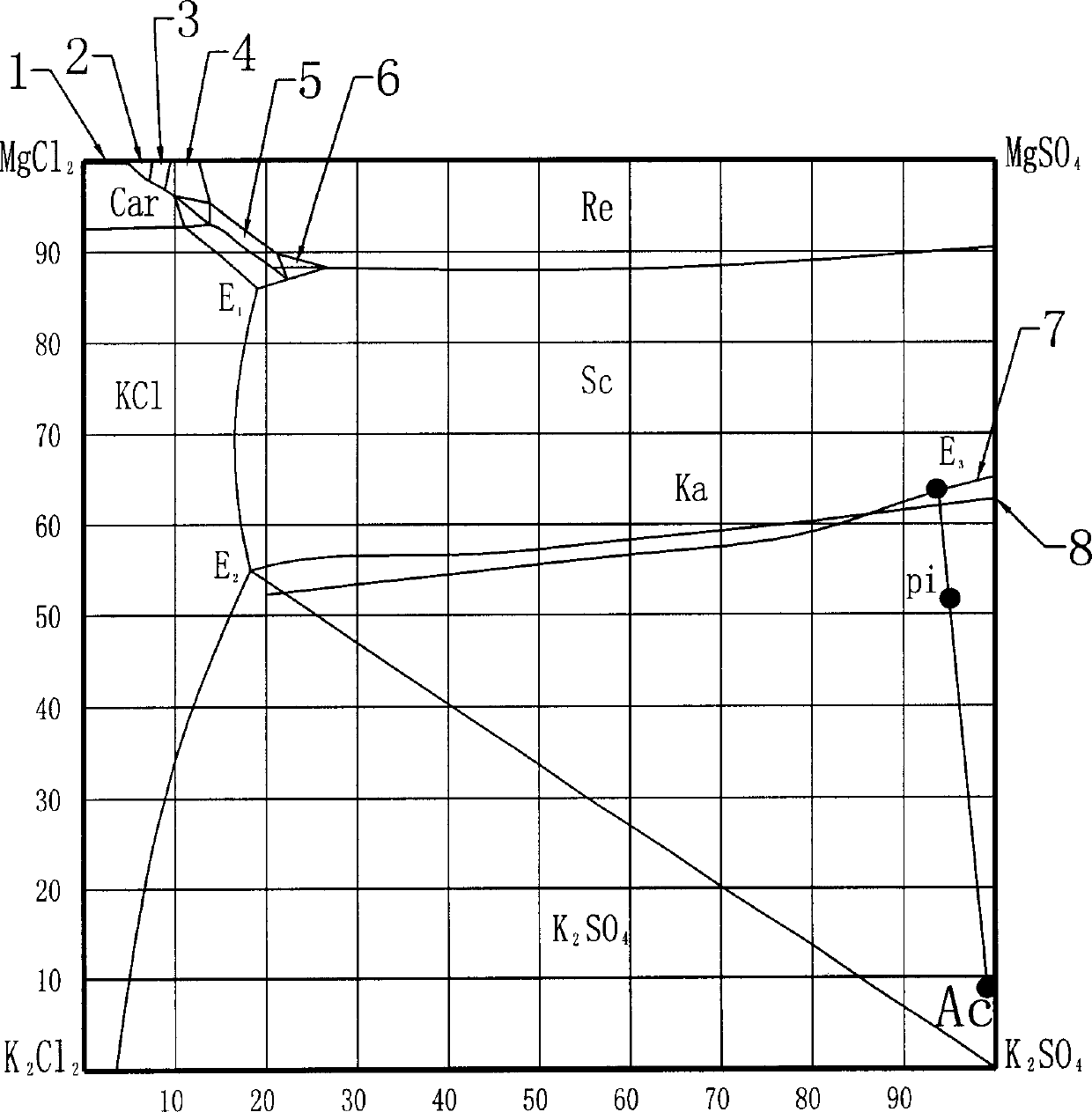

[0036]The crystallization out of the salt field in the potassium mixed salt stage is the potassium mixed salt, and the weight percentage ratio of sulfate ions and potassium ions in the potassium mixed salt should be con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com