Technology for calcining and recycling magnesium desulfurizing byproduct containing magnesium sulfite

A magnesium method desulfurization, magnesium sulfite technology, applied in the direction of sulfur compounds, magnesium oxide, chemical instruments and methods, etc., can solve the problems of reduced investment benefits, reduced activity of magnesium oxide, low utilization value of magnesium sulfite products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] formula:

[0089]Magnesium sulfite water-containing filter cake 100 parts by weight (from the desulfurization by-product of various magnesium method flue gas desulfurization devices, wherein detection obtains about 77% of magnesium sulfite, about 2% of calcium sulfite, about 10% of water content, and the balance cannot Avoided inert impurities (comprising about 1% of magnesium salt and about 9% of other solid content), the parts by weight are based on magnesium sulfite)

[0090] Sulfur 25 parts by weight

[0091] Program:

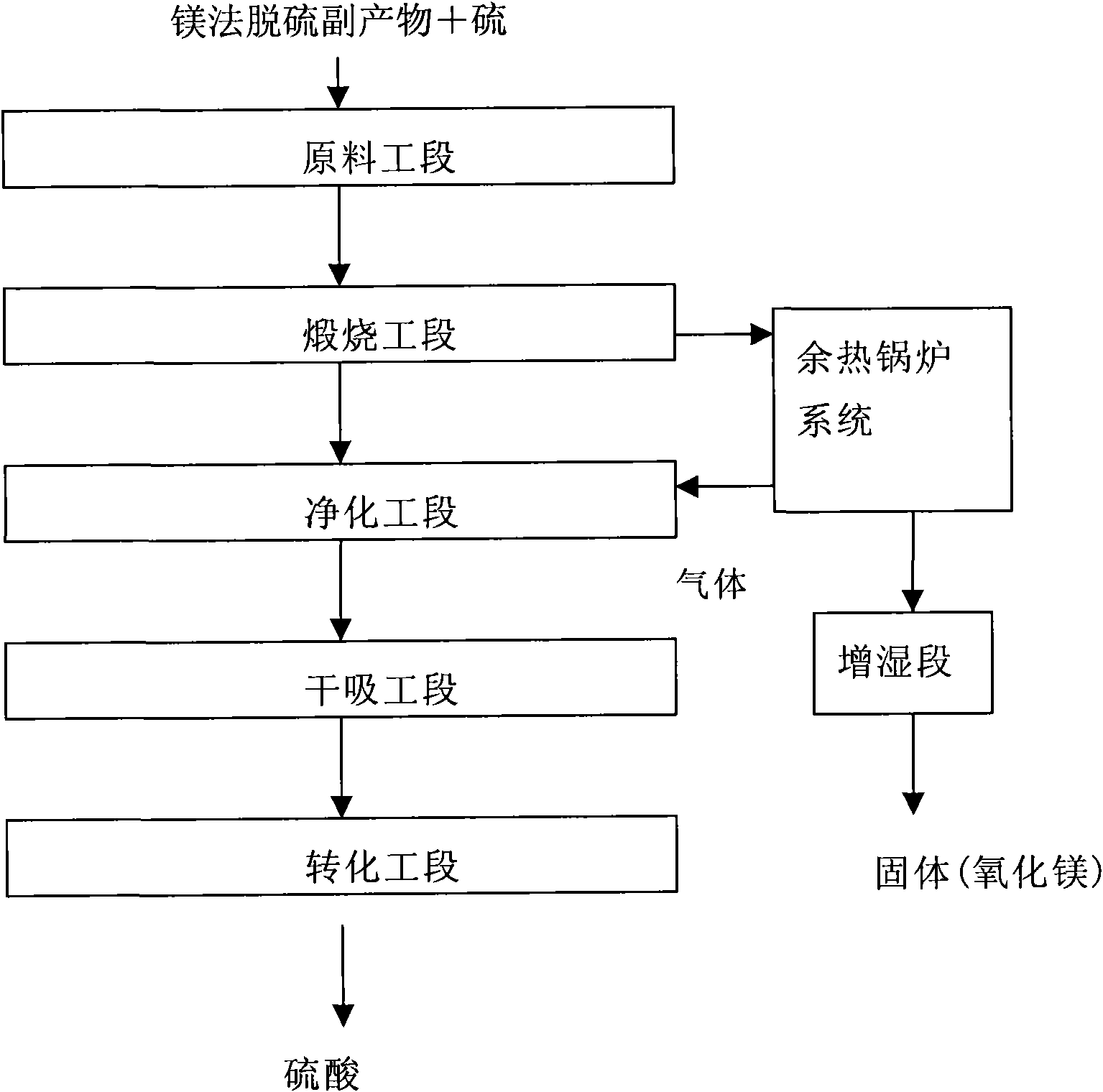

[0092] After the hydrous filter cake of magnesium sulfite and sulfur are transported, sulfuric acid is produced in the following sections of raw material mixing, boiling calcination, closed dilute pickling and purification, and two-transfer and two-suction sections.

[0093] step:

[0094] 1.1 Raw material section

[0095] Magnesium sulfite water-containing filter cake and sulfur are transported into the raw material warehouse for storage separat...

Embodiment 2

[0130] The process of Example 2 is according to Example 1, the difference is that the calcination section of part 1.2 controls the temperature of the calcination furnace to ~850°C.

[0131] Product comprises: product acid is 98% sulfuric acid (total conversion ratio is greater than 99%); Produce 3.82Mpa-450 ℃ medium pressure superheated steam; Contain the magnesium oxide of 70-80% by weight in the solid product containing magnesium oxide (reactivity The discoloration time detected by the citric acid method is about 100 seconds.).

[0132] discuss:

[0133] The product obtained under this temperature is similar to the product obtained in Example 1, but the activity of magnesium oxide produced is slightly reduced.

Embodiment 3

[0135] The process of embodiment 3 is according to embodiment 1, the difference is that the parts of sulfur are 30. Product comprises: product acid is 98% sulfuric acid (total conversion ratio is greater than 99%); Produce 3.82Mpa-450 ℃ medium pressure superheated steam; Contain the magnesium oxide of 70-80% by weight in the solid product containing magnesium oxide (reactivity The discoloration time detected by the citric acid method is about 80 seconds.).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com