Flue gas desulfurization technology applicable to calcium and magnesium desulfuraters

A technology of desulfurization process and desulfurizer, which is applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of desulfurization efficiency, impurity removal effect and quality of by-products cannot be guaranteed, cannot be stable for long-term operation according to local conditions, desulfurization system Low degree of freedom and other problems, to achieve the effect of improving the reliability and flexibility of system operation, improving the degree of freedom and selectivity, and improving the reliability of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

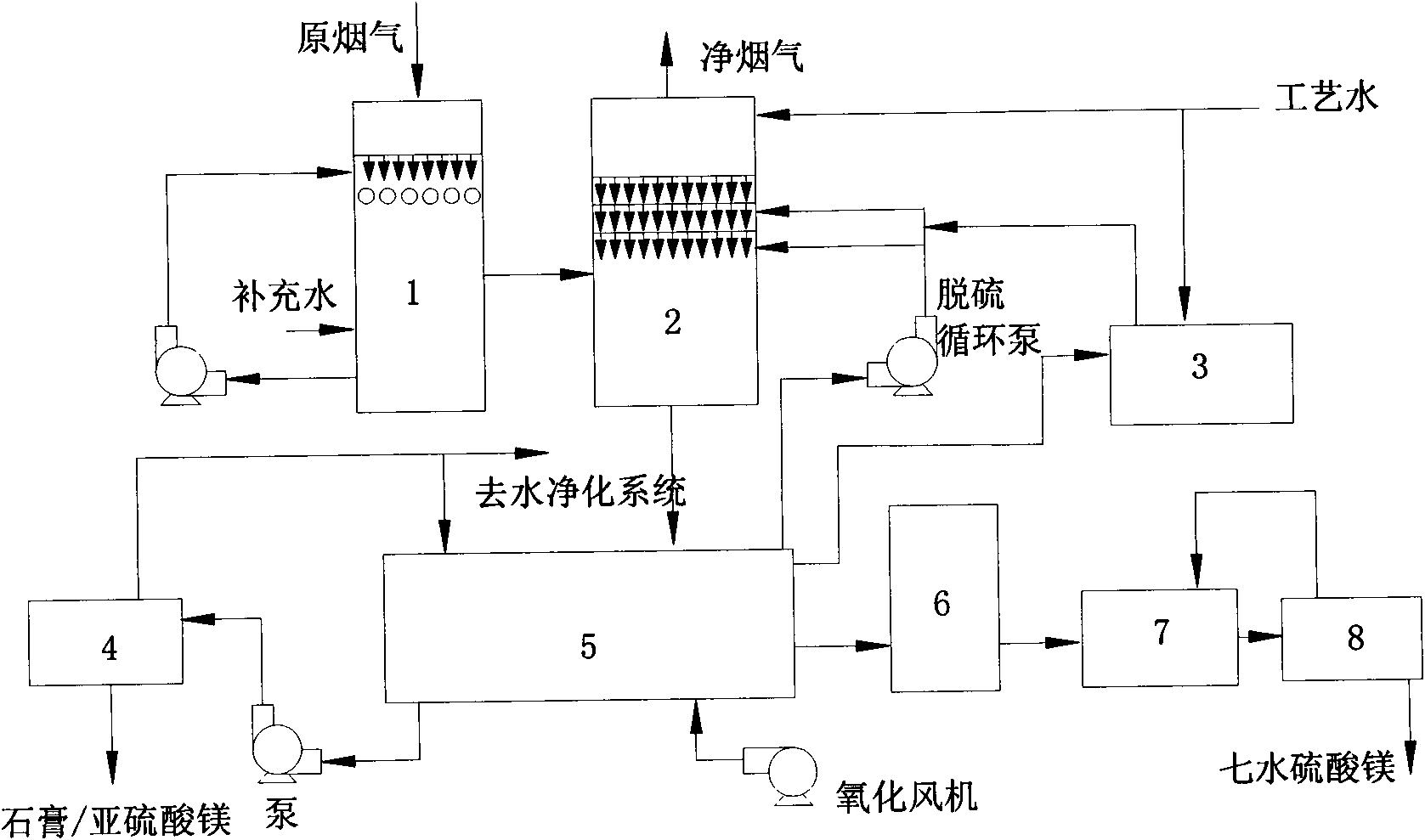

[0018] Depend on figure 1 It can be seen that a flue gas desulfurization process suitable for calcium and magnesium desulfurizers consists of flue gas purification, desulfurizer preparation, flue gas desulfurization, comprehensive pool, dehydration system, and water purification system. The flue gas passes through the flue gas purification tower 1 After preliminary purification and preparation of two desulfurizers 3, it is sent to the flue gas desulfurization tower 2, and after flue gas desulfurization, it is sent to the comprehensive pool 5. When calcium oxide desulfurizer is used, it becomes a gypsum preparation system through the dehydration system 4. When using In the case of magnesium oxide desulfurizer, it becomes a magnesium sulfate heptahydrate preparation system through a water purification system 6, evaporation crystallization 7, and centrifugal drying 8, or a magnesium sulfite preparation system through a dehydration system 4.

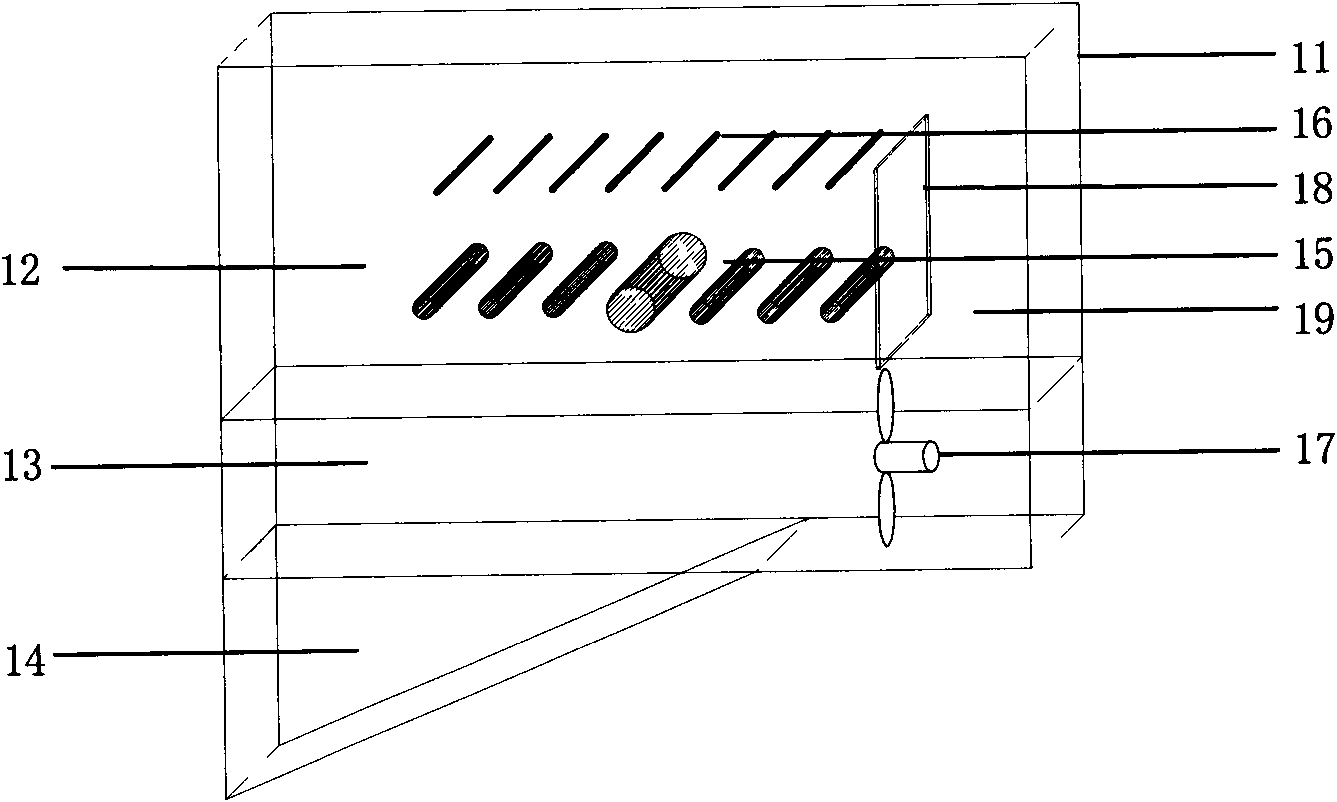

[0019] The flue gas purification adop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com