Connecting joint of flat steel tube concrete column and steel beam and construction method

A technology for concrete-filled steel tubular columns and connecting nodes, which is applied in the processing of building materials, construction, building components, etc., can solve problems such as corrosion of steel structures, and achieve control of construction quality, convenience, speed, stability, reliability, and installation speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

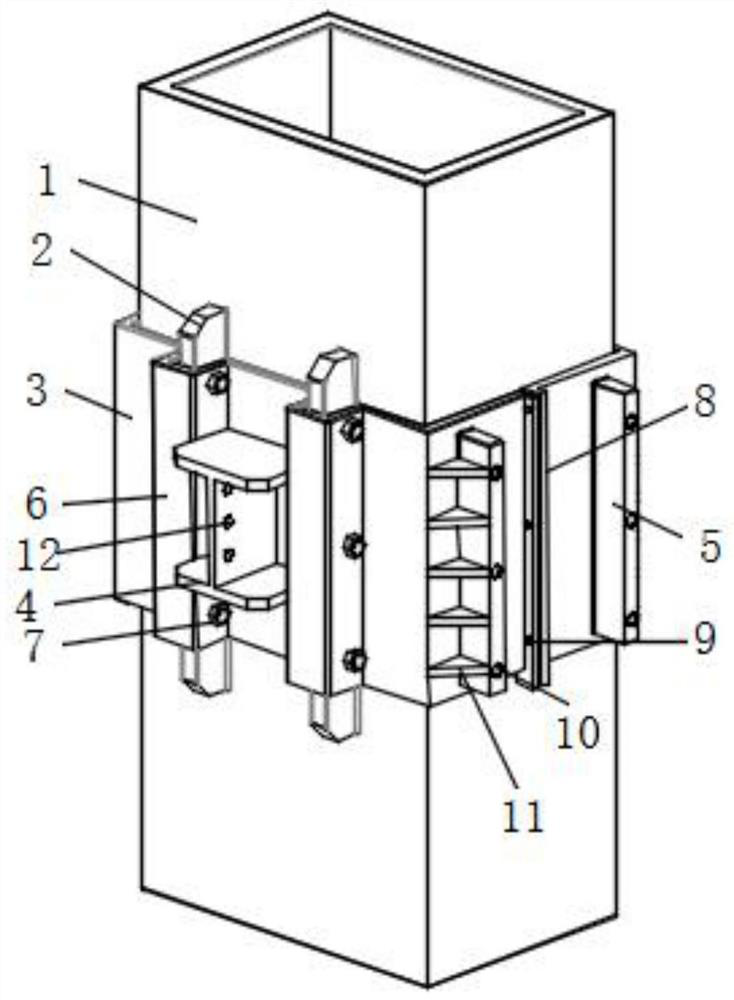

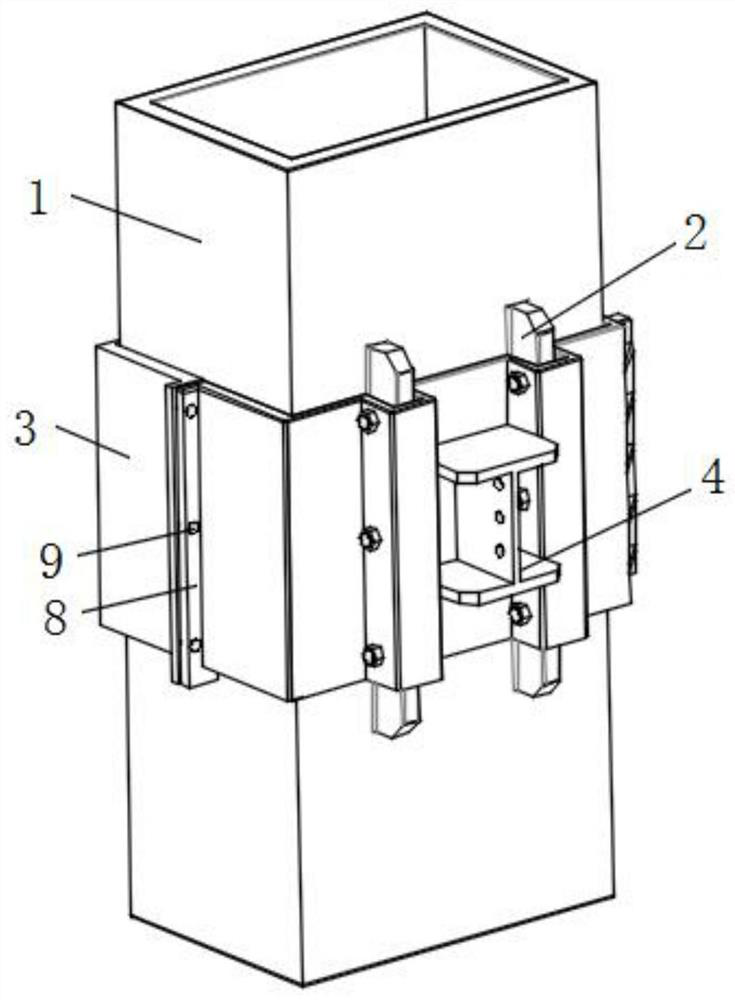

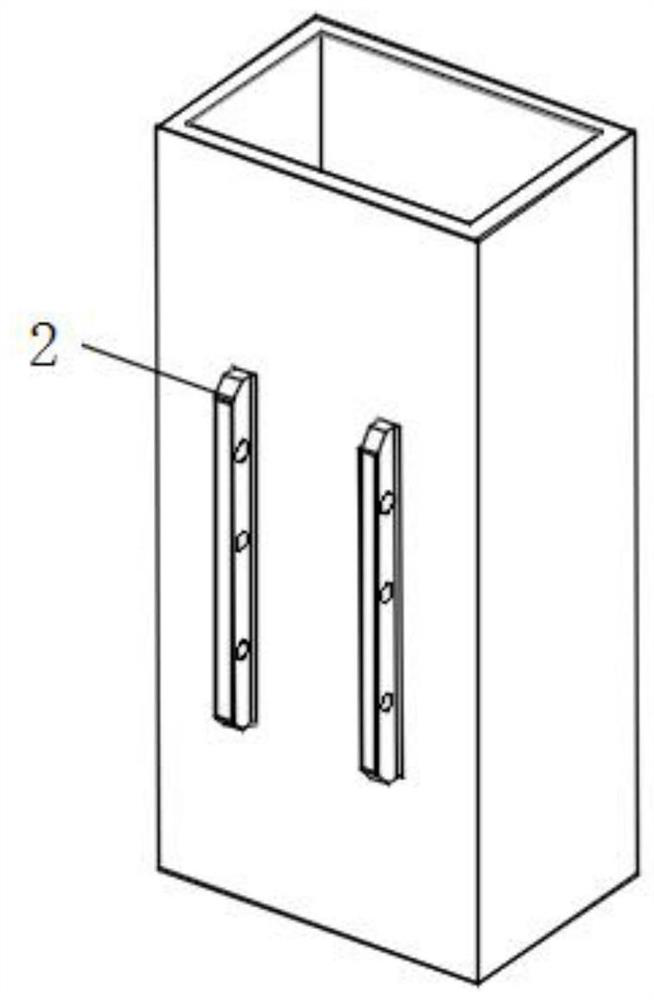

[0036] like Figure 1 to Figure 3 As shown, a connection node between a flat steel pipe concrete column and a steel beam includes a flat steel pipe column 1, and a set of side edge frames 2 are prefabricated on opposite sides of the flat steel pipe column 1, and the flat steel pipe column 1 and the side The edge frame 2 is integrally sprayed with anti-rust paint, and the corrosion phenomenon caused by its weld seam is prevented through prefabrication process and anti-rust paint spraying. Each group of side edge frames 2 is symmetrically provided with two and side edge frames 2 are provided with through holes, and a node assembly is installed on the outside of the side edge frame 2, and the node assembly includes two symmetrically arranged mounting frames 3. The mounting frame 3 is provided with a connecting part 6 adapted to the side edge frame 2, a connecting frame 4 connected with the external steel beam, and an inner plate frame 5 for installing the internal steel beam. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com