System and method for treating acidic wastewater produced in acid making with smelting gas

A technology for acidic wastewater and smelting flue gas, which is applied in the chemical industry, can solve problems such as troublesome treatment process, environmental pollution, single treatment process function, etc., and achieve the effect of reducing operating costs, reducing external drainage, and strong pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

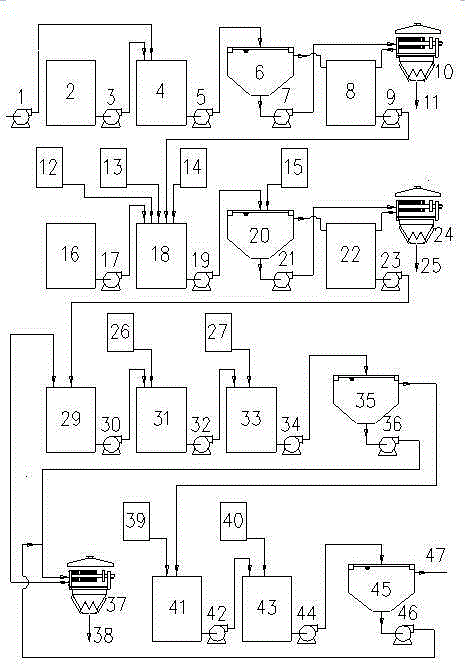

Image

Examples

Embodiment

[0017]A low-concentration sulfur dioxide smelting ring-collected flue gas treatment: adding magnesium oxide into a magnesium oxide preparation tank for preparation, after preparation, it is sent to a magnesium oxide slurry tank through a conveying pump for slurrying, and after the slurry is completed, it is sent to a conveying pump. Magnesium oxide slurry storage tank, the magnesium oxide slurry is sent to the absorption tower for desulfurization by the conveying pump, the fan sends the ring-collected flue gas generated by smelting to the absorption tower, and the circulating pump is turned on to send the magnesium oxide absorption liquid to the absorption tower spray device. It is sprayed down from the spray device, and is in countercurrent contact with the flue gas from the bottom to the top of the absorption tower to absorb the flue gas. After the dust removal reaches the standard, it is emptied through the chimney; after the magnesium oxide absorption liquid is recycled, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com