Boiler water-feeding multifunctional corrosion inhibitor and preparation method thereof

A technology of boiler feed water and corrosion inhibitor, which is applied in the field of multifunctional corrosion inhibitor and multifunctional corrosion inhibitor for boiler feed water treatment. Good effect, high oxygen removal efficiency, and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

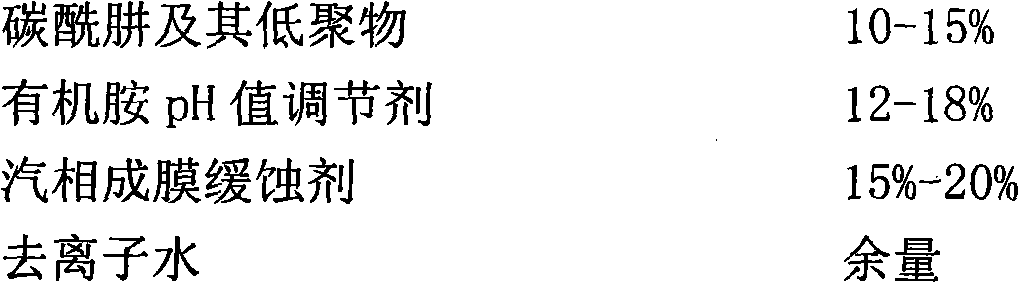

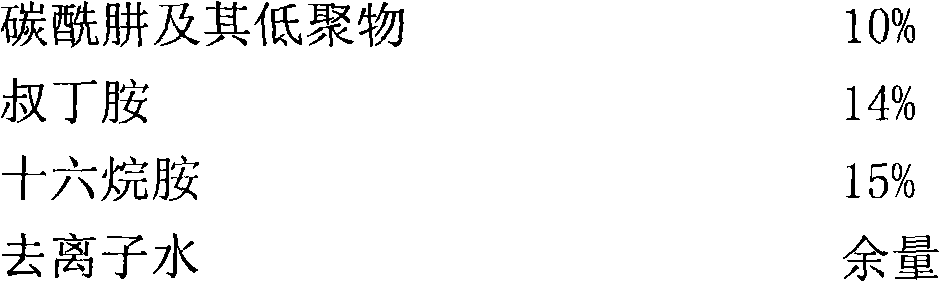

[0029] Boiler feed water multifunctional corrosion inhibitor of the present invention, its batching weight percentage is composed of:

[0030]

[0031] The above ingredients are composed according to weight percentage, and carbohydrazide, n-butylamine, and cetylamine are added to deionized water in sequence, and stirred at room temperature for 20 minutes to fully dissolve, and then the multifunctional corrosion inhibitor for boiler feed water is obtained. .

[0032] The experimental results show that the deoxidation rate of the multifunctional corrosion inhibitor for boiler feed water prepared according to the above formula is 90%, and the corrosion inhibition rate is 89.9%.

Embodiment 2

[0034] Boiler feed water multifunctional corrosion inhibitor of the present invention, its batching weight percentage is composed of:

[0035]

[0036] Wherein the oligomerization content of carbohydrazide and its oligomers with a degree of polymerization not exceeding 5 is 13%.

[0037] The above ingredients are composed according to weight percentage, carbohydrazide and its oligomers, tert-butylamine, and octadecylamine are added to deionized water in sequence, and stirred at room temperature for 20 minutes to fully dissolve, that is, boiler feed water multifunctional Corrosion inhibitor.

[0038] The experimental results show that the deoxidation rate of the boiler feed water multifunctional corrosion inhibitor prepared according to the above formula is 93%, and the corrosion inhibition rate is 90.2%.

Embodiment 3

[0040] Boiler feed water multifunctional corrosion inhibitor of the present invention, its batching weight percentage is composed of:

[0041]

[0042] Wherein the oligomerization content of carbohydrazide and its oligomers with a degree of polymerization not exceeding 5 is 13%.

[0043] The above ingredients are composed according to weight percentage, carbohydrazide and its oligomers, triethanolamine and hexadecylamine are added to deionized water in sequence, and stirred at room temperature for 20 minutes to fully dissolve, that is, boiler feed water Functional corrosion inhibitor.

[0044] The experimental results show that the deoxidation rate of the boiler feed water multifunctional corrosion inhibitor prepared according to the above formula is 97%, and the corrosion inhibition rate is 93.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com