Anti-oxidative non-aqueous decarbonization solution for trapping carbon dioxide in mixed gas

A carbon dioxide and mixed gas technology, applied in gas treatment, air quality improvement, chemical instruments and methods, etc., can solve the problems of high regeneration energy consumption, easy to be oxidized by oxygen, low decarbonization ability, etc., and achieve low regeneration energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The performance investigation of embodiment one non-aqueous solution being oxidized

Embodiment 11

[0067] Oxidation experiment of embodiment 1.1 absorption process

[0068] First, prepare two 150g non-aqueous solutions of 30wt% EMEA+70wt% DEEA, without adding antioxidants, take samples, and then put them into two 300ml autoclaves respectively and number the two autoclaves as 1 and 2. Secondly, since variables need to be controlled in this experiment, it is necessary to ensure that the two kettles have different gas compositions, that is, the No. 1 kettle is fed with 10% CO 2 , N 2 balance and 13% O 2 , 10% CO into No. 2 kettle 2 , N 2 Equilibrium, other variables such as temperature, pressure, etc. are consistent. Therefore, in this experiment, an oil bath was used to keep the temperature of the two kettles at 70°C, and the gas pressure of the two kettles was 0.7MPa. Finally, under the above conditions, reacted continuously for 16 days, during which samples were taken, and regeneration was carried out to investigate the mass fraction of EMEA.

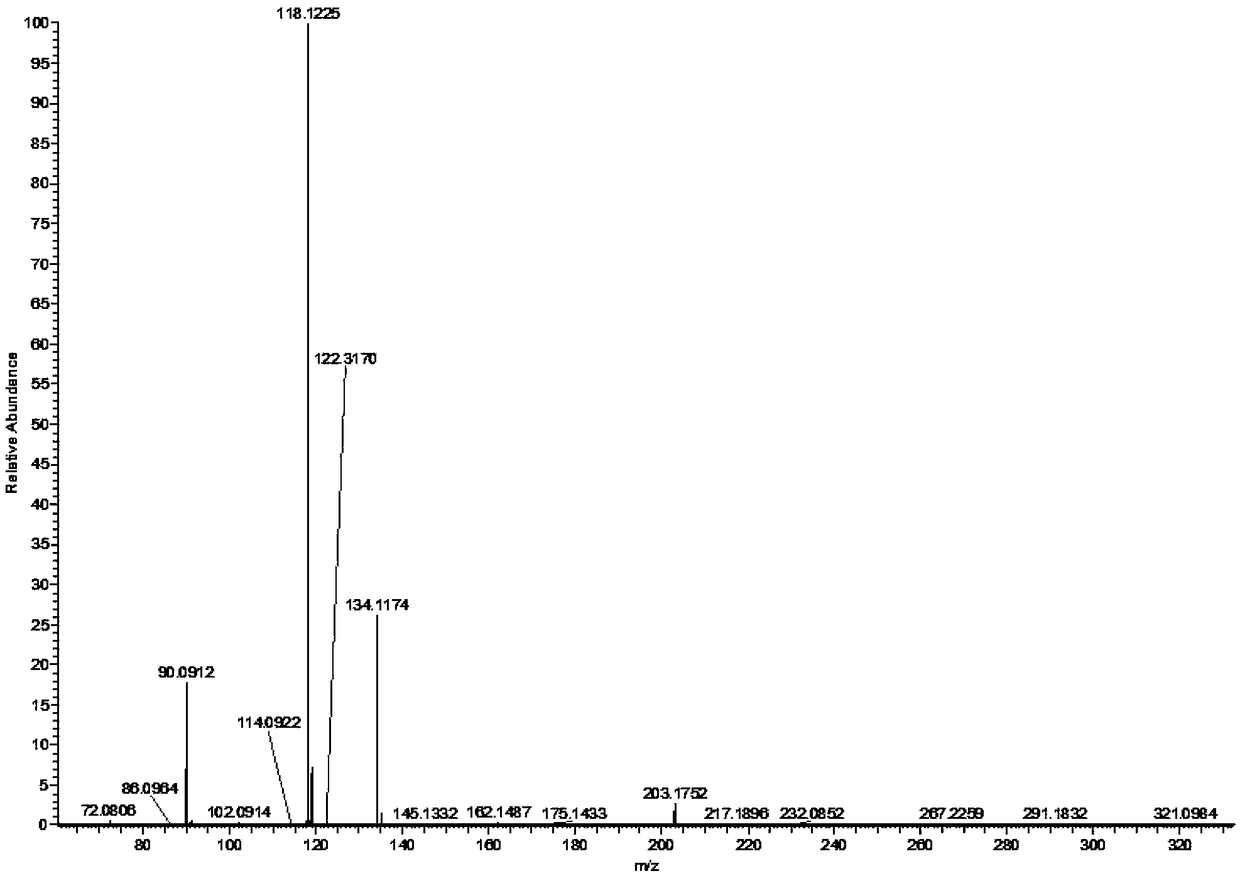

[0069] figure 1 It is ...

Embodiment 12

[0070] Embodiment 1.2 Solution absorption and desorption performance

[0071] Using CO 2 Absorption and desorption device, investigated the CO of the solution after the two tanks reacted and regenerated 2 Absorption and desorption performance (100g solution), and compared with the blank group. The absorption temperature is 40°C, the desorption temperature is 100°C, and the reaction pressure is normal pressure. The fresh solution is 30wt% EMEA+70wt% DEEA, and its absorption curve and desorption curve are shown in section 3.2 of this paper.

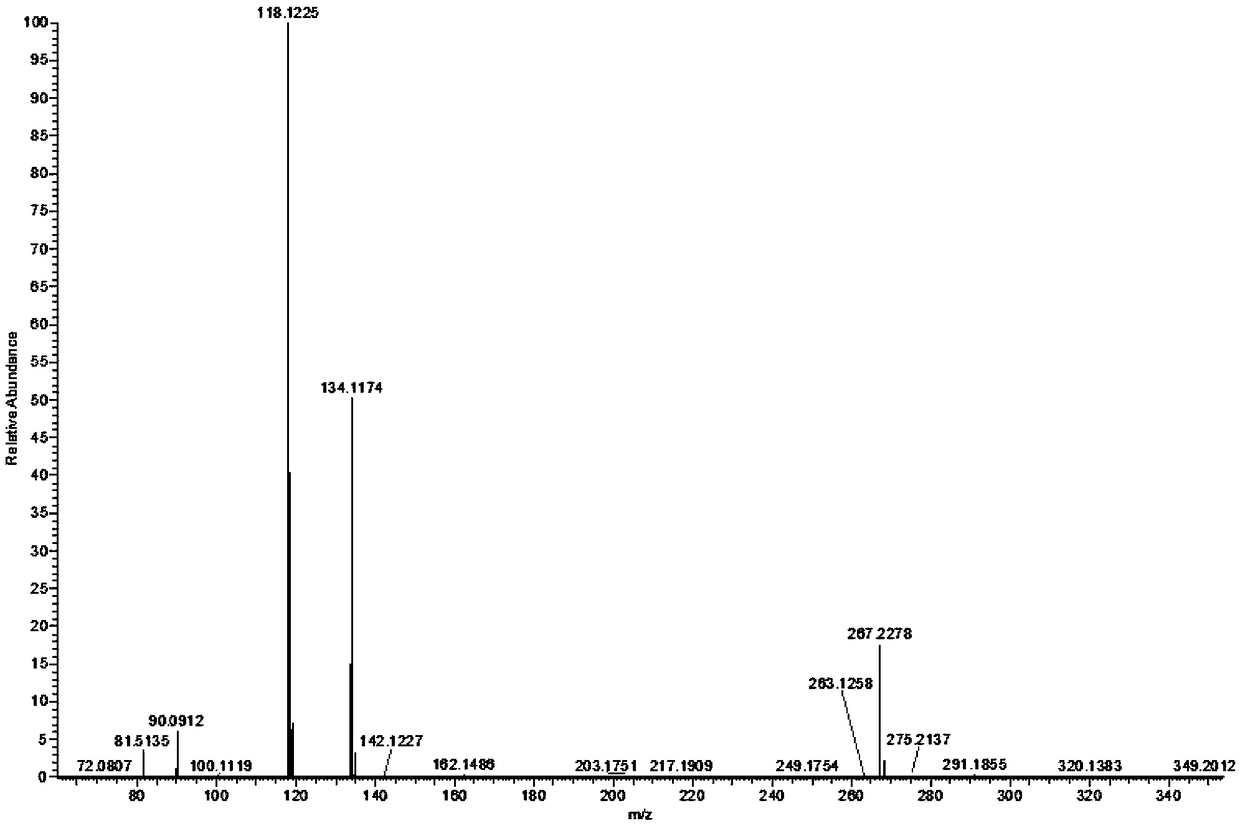

[0072] figure 2 For the absorption process, CO 2 Absorption (β 1 , mol CO 2 / mol EMEA) versus time (t, min). As can be seen from the figure, the three curves in the first 10 minutes basically overlap, indicating that the three solutions CO 2 The absorption rate is almost the same; the curve of the fresh solution still shows a rapid upward trend at 10-20 minutes, the curve of the No. 2 kettle rises rapidly with a certain slope and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com