Special nanometer composite seal paint for woodware and preparing method thereof

A nano-composite and sealing paint technology, applied in coatings and other directions, can solve problems such as affecting the performance and use value of coatings, the compatibility of organic media, and reducing product quality. low pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

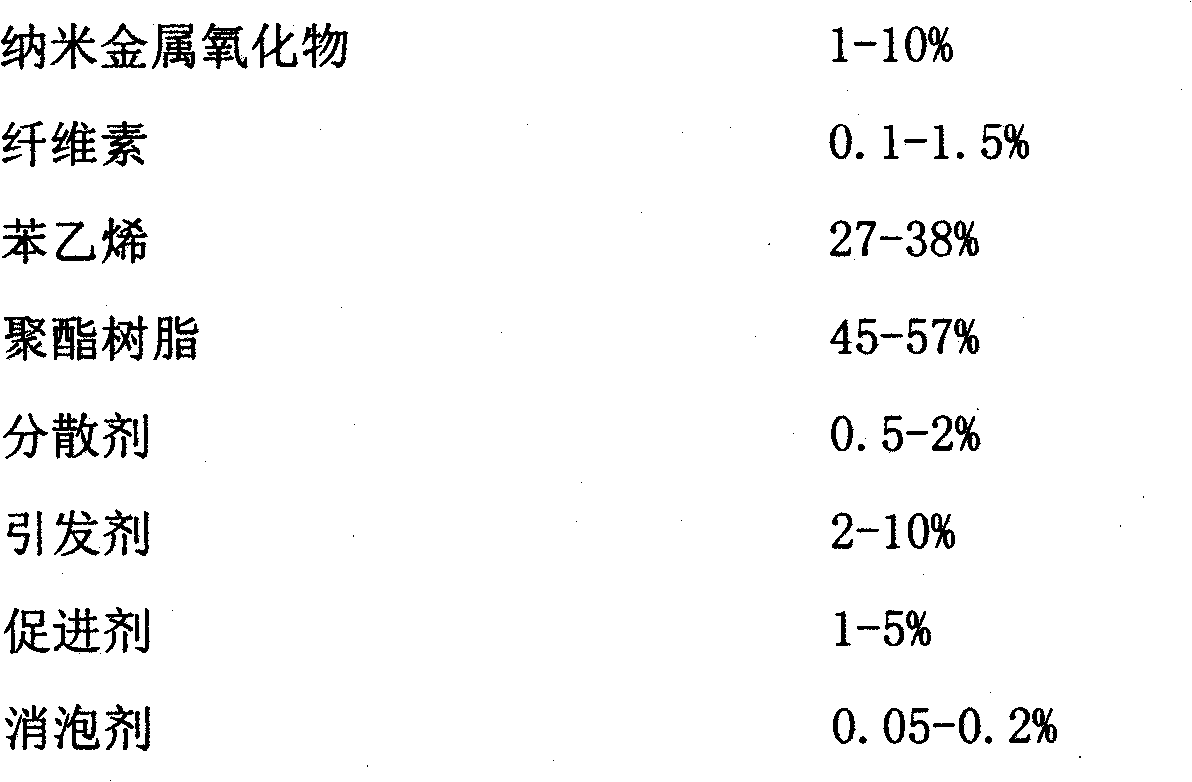

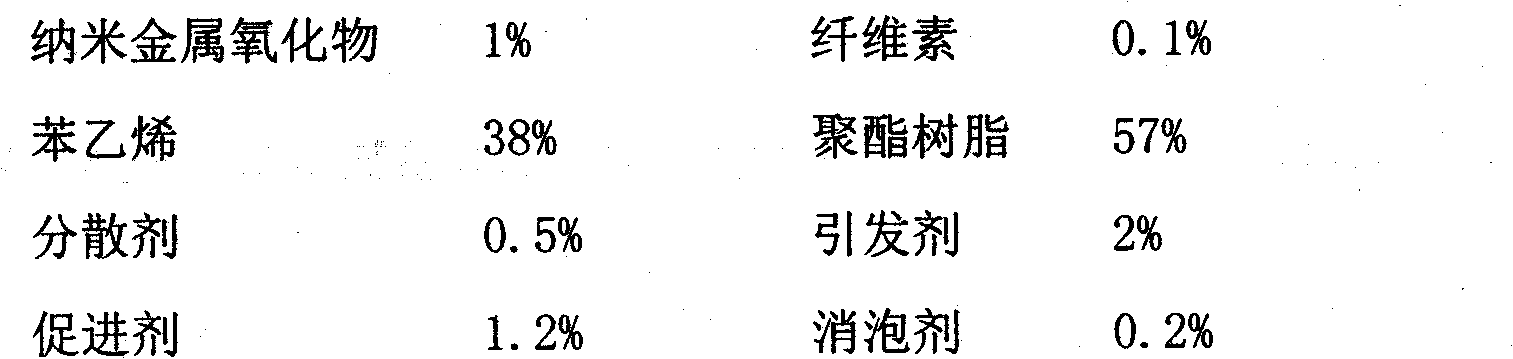

[0037] Components and mass percentages thereof of a kind of wood nanocomposite special sealer are as follows:

[0038]

[0039] Wherein: the nano-metal oxide is nano-zinc oxide with a particle size of 20 nanometers;

[0040] Described cellulose is sodium carboxymethyl cellulose;

[0041] Described polyester resin is polyethylene terephthalate;

[0042] Described dispersant is sodium lignosulfonate;

[0043] Described initiator is benzoyl peroxide;

[0044] Described accelerator is cobalt naphthenate;

[0045] Described defoamer is silicone defoamer.

[0046] A kind of preparation method of wood nanocomposite special sealer, its specific steps are as follows:

[0047] (1) Surface modification of nanometer metal oxides

[0048] According to the ratio of nano-zinc oxide: toluene: the mass (g) of sodium carboxymethyl cellulose is 1: 40: 0.1, first sodium carboxymethyl cellulose is added in toluene, stirred until sodium carboxymethyl cellulose A toluene solution of sodium...

Embodiment 2

[0054] Components and mass percentages thereof of a kind of wood nanocomposite special sealer are as follows:

[0055]

[0056] Wherein: the nano-metal oxide is nano-silicon dioxide with a particle size of 20 nanometers;

[0057] Described cellulose is hydroxypropyl methylcellulose;

[0058] Described polyester resin is polydimethyl terephthalate;

[0059] Described dispersant is glyceryl tristearate;

[0060] Described initiator is cyclohexanone peroxide;

[0061] Described accelerator is diethylaniline;

[0062] Described defoamer is silicone defoamer.

[0063] A kind of preparation method of wood nanocomposite special sealer, with embodiment 1, wherein:

[0064] In step (1), the ratio of nano-silica: toluene: the mass (g) of hydroxypropyl methylcellulose is 1: 60: 0.15, the reaction temperature is 40°C, the modification reaction time is 4h, centrifuged : the ratio of the mass (g) of absolute ethanol is 1: 20, the centrifuged sediment is washed 5 times with absolute...

Embodiment 3

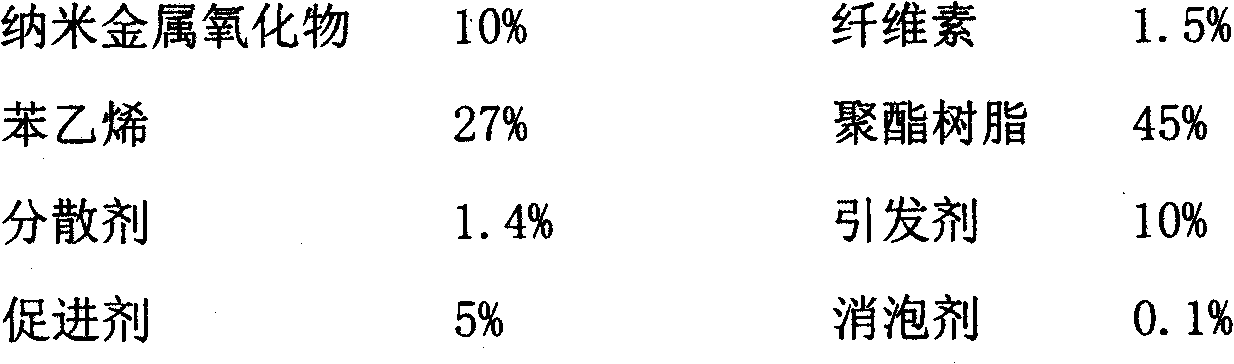

[0068] Components and mass percentages thereof of a kind of wood nanocomposite special sealer are as follows:

[0069]

[0070] Wherein: the nano-metal oxide is nano-titanium dioxide with a particle size of 15 nanometers;

[0071] Described cellulose is hydroxypropyl cellulose;

[0072] Described polyester resin is polydimethylphthalate;

[0073] Described dispersant is glyceryl tristearate;

[0074] Described initiator is methyl ethyl ketone peroxide;

[0075] Described accelerator is dimethylaniline;

[0076] Described defoamer is silicone defoamer.

[0077] A kind of preparation method of wood nanocomposite special sealer, with embodiment 1, wherein:

[0078] In the (1) step, the ratio of nano-titanium dioxide: toluene: the mass (g) of hydroxypropyl cellulose is 1: 45: 0.056, the reaction temperature is 80°C, the modification reaction time is 3h, centrifugal precipitation: dehydrated alcohol The mass (g) ratio of the solution was 1:15, the centrifuged precipitate w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com