Oil-based drilling fluid blocking agent and preparation method thereof

An oil-based drilling fluid and plugging agent technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve problems such as difficulty in uniform dispersion, poor compatibility of base oil, environmental pollution, etc. Filter loss effect, improve plugging performance, cost and environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

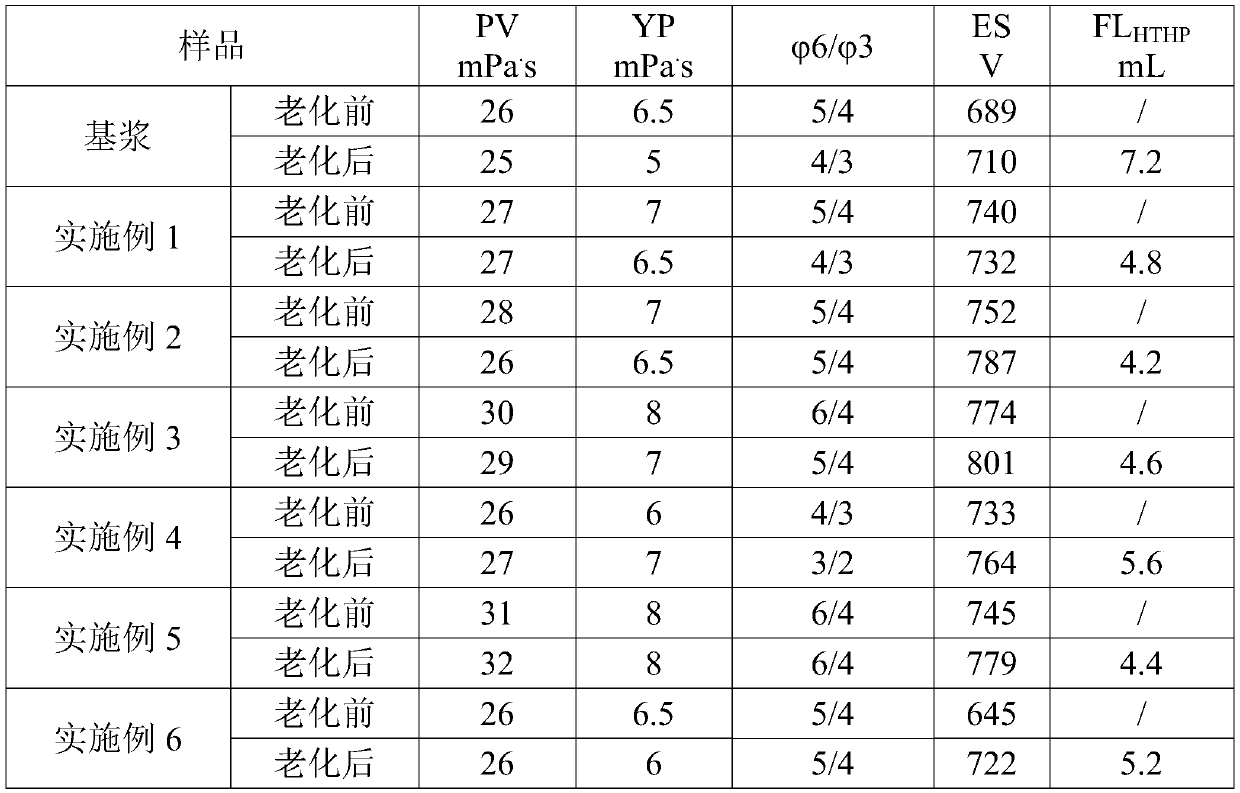

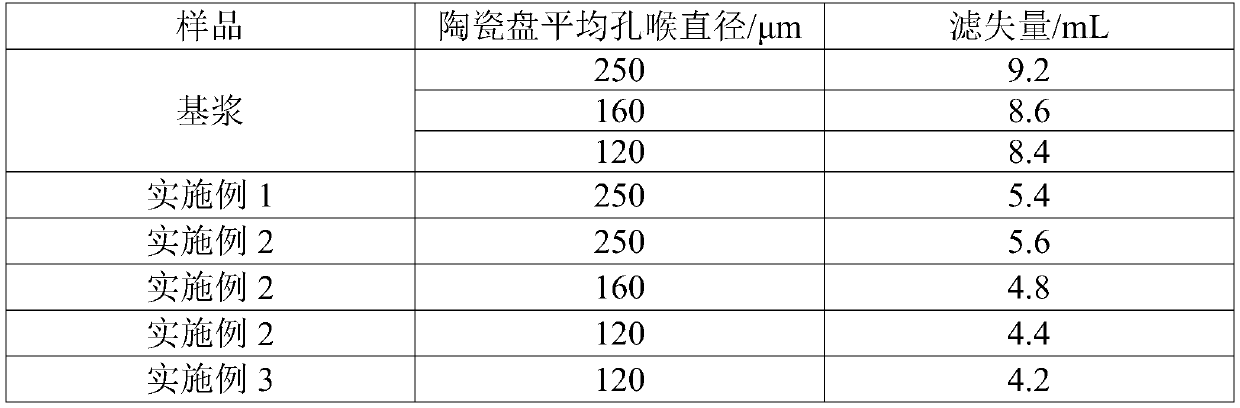

Examples

Embodiment 1

[0027] A kind of oil base drilling fluid plugging agent, its preparation method is as follows:

[0028] S1. Put 100 parts by weight of the olive pomace material on the tray of the blast oven, heat up to 40°C, and dry for 12 hours. During this period, take out the tray every 2 hours to turn the olive pomace material and then put it back in the oven, and continue to bake Dry, stop heating after 12 hours, take it out after cooling to room temperature naturally;

[0029] S2. Pour the product dried in step S1 into a ball mill, add 0.2 parts by weight of magnesium stearate, blend and pulverize, and pass through a 60-mesh sieve to obtain the oil-based drilling fluid plugging agent.

Embodiment 2

[0031] A kind of oil base drilling fluid plugging agent, its preparation method is as follows:

[0032] S1. Put 100 parts by weight of the olive pomace material on the tray of the blast oven, heat up to 40°C, and dry for 12 hours. During this period, take out the tray every 2 hours to turn the olive pomace material and then put it back in the oven, and continue to bake Dry, stop heating after 12 hours, take it out after cooling to room temperature naturally;

[0033] S2. Pour the product dried in step S1 into a ball mill, add 0.2 parts by weight of magnesium stearate, blend and pulverize, and pass through a 100-mesh sieve to obtain the oil-based drilling fluid plugging agent.

Embodiment 3

[0035] A kind of oil base drilling fluid plugging agent, its preparation method is as follows:

[0036] S1. Put 100 parts by weight of the olive pomace material on the tray of the blast oven, heat up to 40°C, and dry for 12 hours. During this period, take out the tray every 2 hours to turn the olive pomace material and then put it back in the oven, and continue to bake Dry, stop heating after 12 hours, take it out after cooling to room temperature naturally;

[0037] S2. Pour the product dried in step S1 into a ball mill, add 0.2 parts by weight of magnesium stearate, blend and pulverize, and pass through a 150-mesh sieve to obtain the oil-based drilling fluid plugging agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com