Novel high-viscosity high-fluidity magnesium refractory mortar

A high-fluidity, high-viscosity technology, applied in the field of new high-viscosity and high-fluidity magnesia refractory clay, can solve the problems of low strength, poor workability, and reduced water retention performance of refractory clay, and achieve enhanced high temperature performance and improved erosion resistance. , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

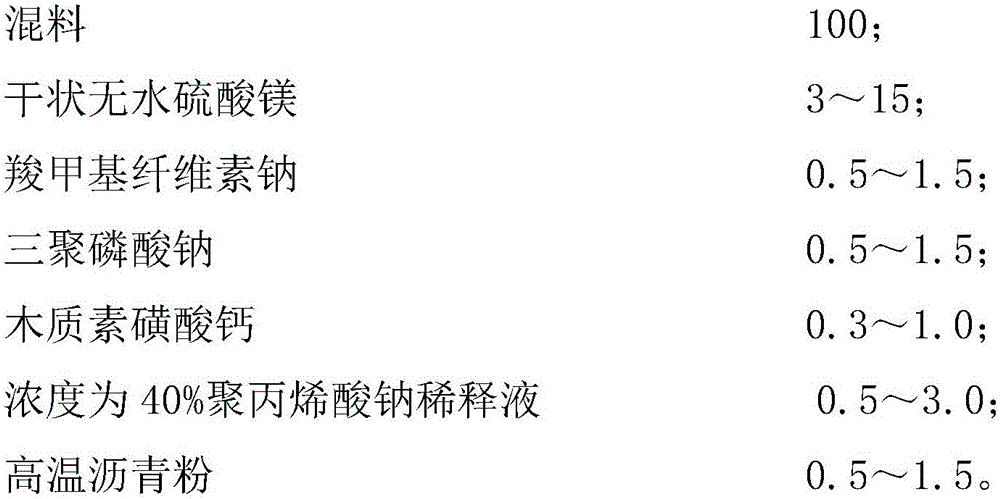

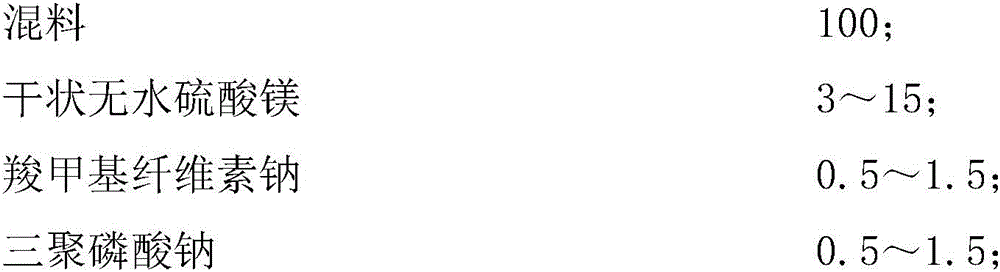

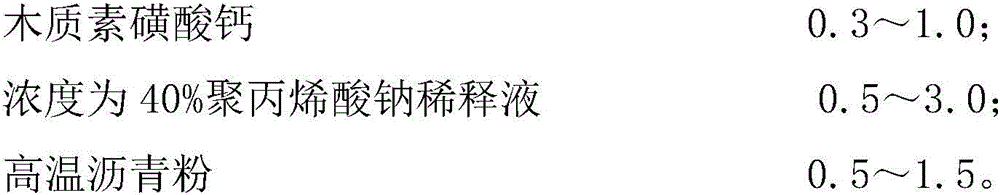

[0033] 50 parts by weight of magnesia fine powder, 50 parts by weight of waste magnesia carbon brick powder, 4 parts by weight of dry anhydrous magnesium sulfate, 0.5 parts by weight of sodium carboxymethyl cellulose, 0.5 parts by weight of tripolyphosphoric acid Sodium, 0.3 parts by weight of calcium lignosulfonate, 0.5 parts by weight of high-temperature asphalt powder, and 0.5 parts by weight of a 40% sodium polyacrylate dilution are weighed in proportion and fully mixed uniformly to prepare the novel high-viscosity high Fluid magnesia refractory clay.

[0034] The particle size of the magnesia fine powder and the waste magnesia carbon brick fine powder in this embodiment is required to be ≤0.074 mm, and the particle size of the high-temperature asphalt powder is required to be ≤0.08 mm.

Embodiment 2

[0036] 55 parts by weight of magnesia fine powder, 45 parts by weight of waste magnesia carbon brick powder, 6 parts by weight of dry anhydrous magnesium sulfate, 1 part by weight of sodium carboxymethyl cellulose, 0.5 parts by weight of tripolyphosphoric acid Sodium, 0.3 parts by weight of calcium lignosulfonate, 0.5 parts by weight of high-temperature asphalt powder, and 1 part by weight of a 40% sodium polyacrylate dilution are weighed in proportion and fully mixed uniformly to prepare the novel high-viscosity high Fluid magnesia refractory clay.

[0037] The particle size of the magnesia fine powder and the waste magnesia carbon brick fine powder in this embodiment is required to be ≤0.074 mm, and the particle size of the high-temperature asphalt powder is required to be ≤0.08 mm.

Embodiment 3

[0039] 63 parts by weight of magnesia fine powder, 37 parts by weight of waste magnesia carbon brick powder, 8 parts by weight of dry anhydrous magnesium sulfate, 1 part by weight of sodium carboxymethyl cellulose, 0.7 parts by weight of tripolyphosphoric acid Sodium, 0.6 parts by weight of calcium lignosulfonate, 1 part by weight of high-temperature asphalt powder, and 1.5 parts by weight of a 40% sodium polyacrylate dilution are weighed in proportion and fully mixed uniformly to prepare the novel high-viscosity high Fluid magnesia refractory clay.

[0040] The particle size of the magnesia fine powder and the waste magnesia carbon brick fine powder in this embodiment is required to be ≤0.074 mm, and the particle size of the high-temperature asphalt powder is required to be ≤0.08 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com