High-foaming reinforcing rubber sheet

A reinforcing film and high-foaming technology, applied in the direction of adhesives, epoxy resin glue, rubber derivative glue, etc., can solve the problems of fixed thickness and unsatisfactory reinforcement effect, so as to improve the bonding force and excellent damping and shock absorption effect , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

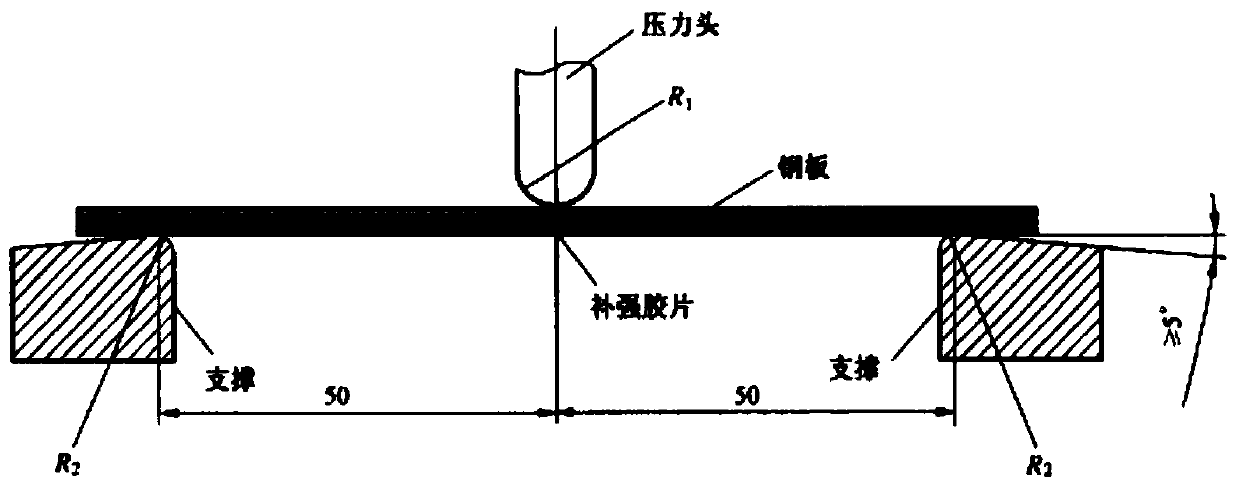

Problems solved by technology

Method used

Image

Examples

Embodiment 1

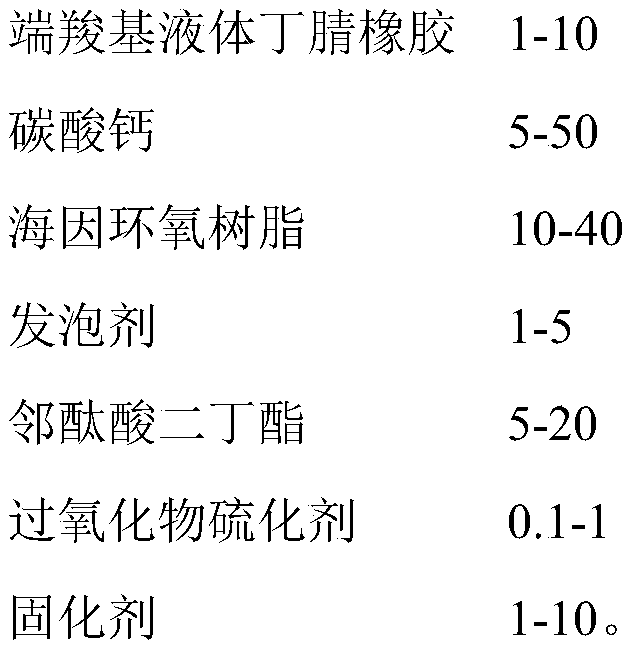

[0019] A kind of high-foaming reinforcing film, is made up of each material of following mass parts:

[0020]

[0021] In this embodiment, the epoxy value of hydantoin epoxy resin is 0.2602 mol / 100g, and the average molecular weight is 769; the content of acrylonitrile in the carboxyl-terminated liquid nitrile rubber is 15%.

Embodiment 2

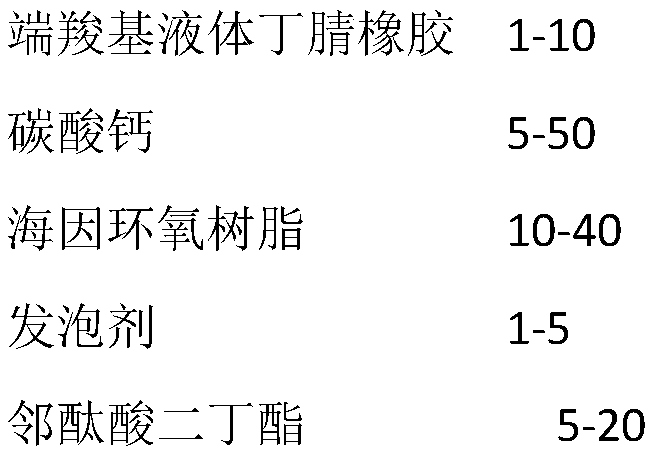

[0023] A kind of high-foaming reinforcing film, is made up of each material of following mass parts:

[0024]

[0025] In this embodiment, the epoxy value of hydantoin epoxy resin is 0.2602 mol / 100g, and the average molecular weight is 769; the content of acrylonitrile in the carboxyl-terminated liquid nitrile rubber is 15%.

Embodiment 3

[0027] A kind of high-foaming reinforcing film, is made up of each material of following mass parts:

[0028]

[0029]

[0030] In this embodiment, the epoxy value of hydantoin epoxy resin is 0.2602 mol / 100g, and the average molecular weight is 769; the content of acrylonitrile in the carboxyl-terminated liquid nitrile rubber is 15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com