Photovoltaic cable sheath material and preparation method thereof

A sheath material, photovoltaic cable technology, applied in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of material mechanical properties, low temperature resistance and other performance degradation, and achieve good solubility and flow properties, high Insulation resistance, the effect of excellent flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

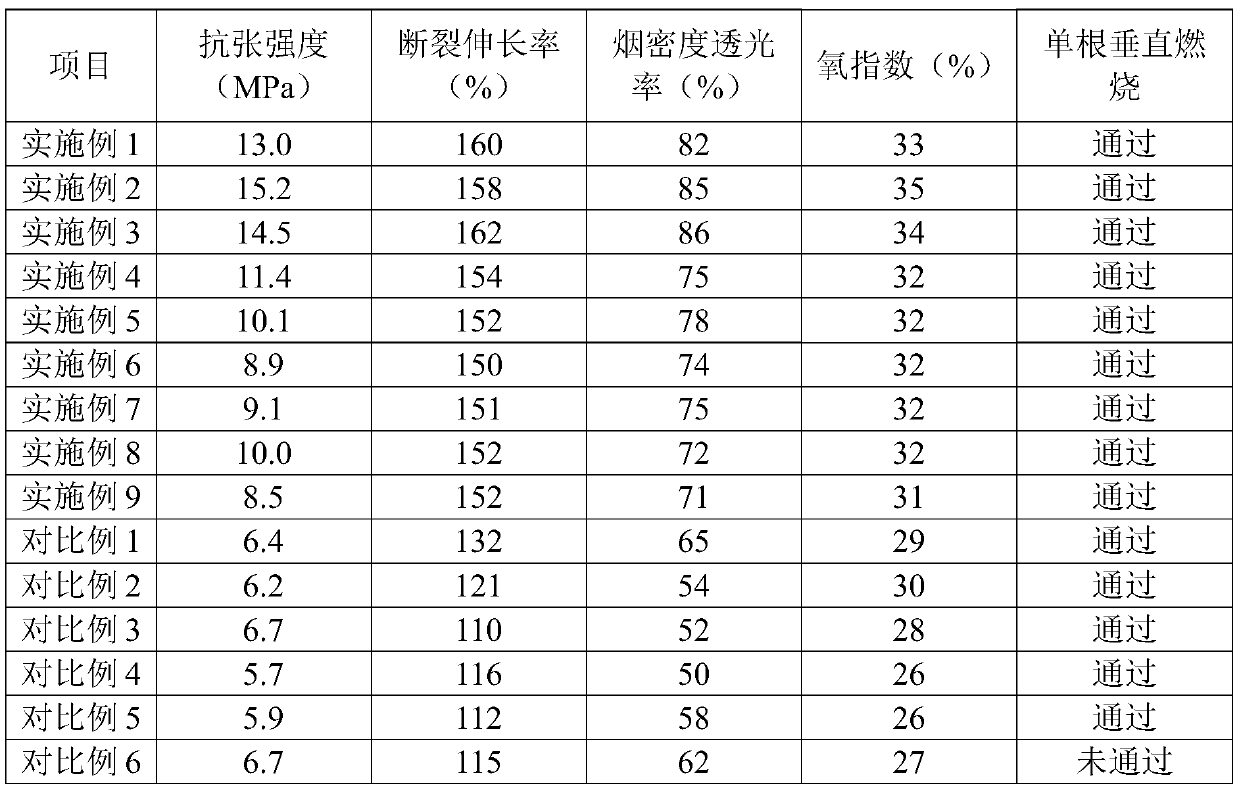

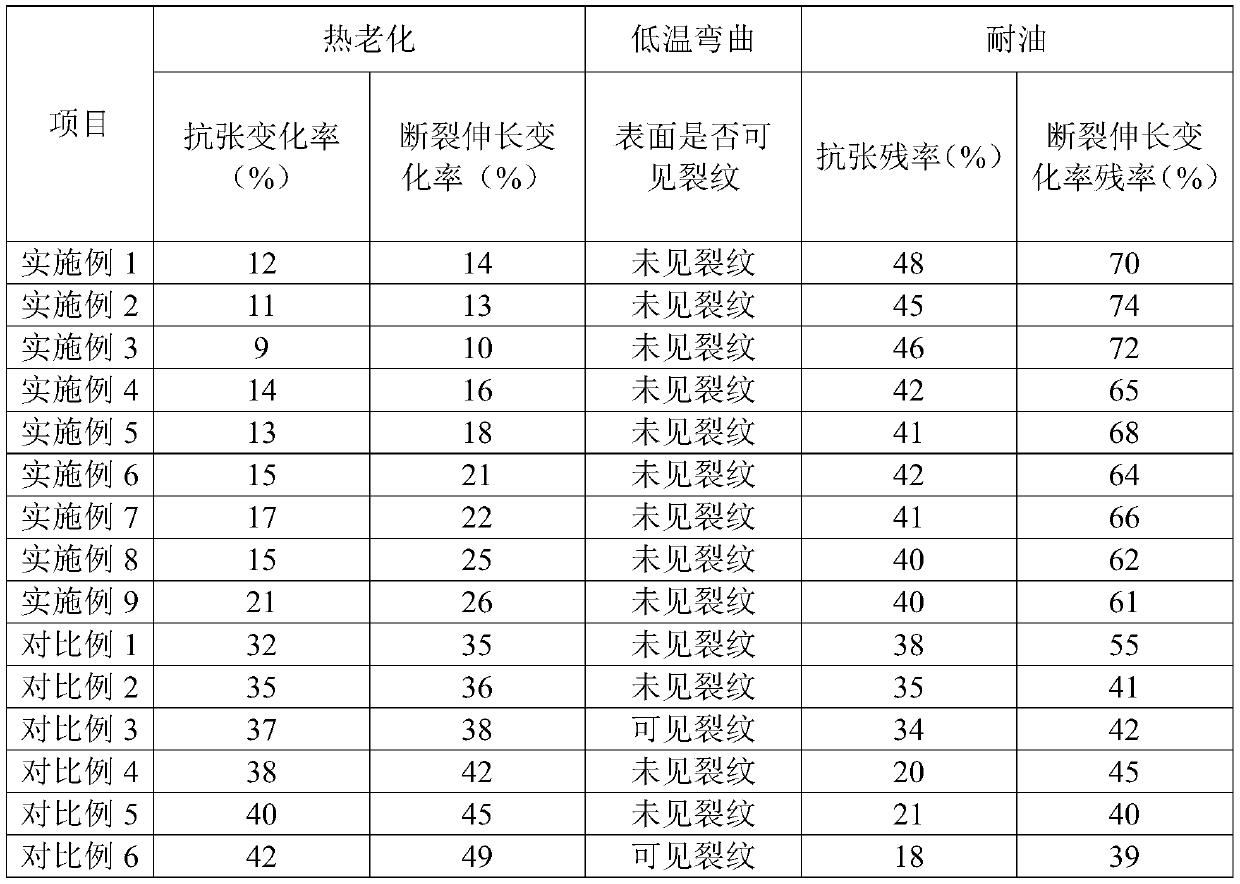

Examples

Embodiment 1

[0053] This embodiment provides a photovoltaic cable sheath material, which comprises: hyperbranched polyethylene (branching degree is 100 branches / 1000C, number average molecular weight is 5×10 5 ) 40%, aluminum hydroxide (fineness of 1 μm) 42%, microcapsule red phosphorus (fineness of 5 μm) 7%, maleic anhydride grafted EVA (grafting rate of 3%, melt index of 6g / 10min, The weight percentage of EVA is 30%) 6%, calcium stearate 1%, zinc stearate 1%, silicone masterbatch 2% and γ-(2,3-epoxypropoxy) propyl trimethyl Oxysilane 1%.

[0054] The preparation method of the photovoltaic cable sheath material provided in this embodiment comprises the following steps:

[0055] (1) Hyperbranched polyethylene, aluminum hydroxide, microcapsule red phosphorus, maleic anhydride grafted EVA, calcium stearate, zinc stearate, silicone masterbatch and γ-(2,3- Glycidoxy)propyltrimethoxysilane is mixed, melt-blended at 160°C for 15 minutes using an internal mixer, and then made into granules thro...

Embodiment 2

[0058] This embodiment provides a photovoltaic cable sheath material, the photovoltaic cable sheath material comprises: hyperbranched polyethylene (branching degree is 130 branches / 1000C, number average molecular weight is 6×10 5 ) 20%, aluminum hydroxide (fineness is 2μm) 50%, microcapsule red phosphorus (fineness is 10μm) 10%, maleic anhydride grafted EVA (graft rate is 5%, melt index is 10g / 10min, The weight percent content of EVA is 40%) 10%, calcium laurate 3%, zinc laurate 1%, silicone masterbatch 3% and gamma-mercaptopropyl triethoxysilane 3%.

[0059] The preparation method of the photovoltaic cable sheath material provided in this embodiment comprises the following steps:

[0060] (1) Hyperbranched polyethylene, aluminum hydroxide, microcapsule red phosphorus, maleic anhydride grafted EVA, calcium laurate, zinc laurate, silicone masterbatch and γ-mercaptopropyltriethoxy After the silane is mixed, use an internal mixer to melt and blend at 175°C for 25 minutes, and th...

Embodiment 3

[0063] This embodiment provides a photovoltaic cable sheath material, which includes: hyperbranched polyethylene (branching degree is 110 branches / 1000C, number average molecular weight is 7×10 5 ) 40%, aluminum hydroxide (fineness is 1 μm) 40%, microcapsule red phosphorus (fineness is 10 μm) 5%, maleic anhydride grafted EVA (grafting rate is 4%, melt index is 5g / 10min, The weight percent content of EVA is 35%) 8%, calcium palmitate 3%, zinc palmitate 1%, silicone masterbatch 1% and gamma-aminoethylaminopropyl trimethoxysilane 2%.

[0064] The preparation method of the photovoltaic cable sheath material provided in this embodiment comprises the following steps:

[0065](1) Hyperbranched polyethylene, aluminum hydroxide, microcapsule red phosphorus, maleic anhydride grafted EVA, calcium palmitate, zinc palmitate, silicone masterbatch and γ-aminoethylaminopropyl trimethyl After the oxysilane is mixed, use an internal mixer to melt and blend at 170°C for 10 minutes, and then pas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com