Heat-resistant and salt-resistant profile controlling agent and preparation method thereof

A technology of temperature and salt resistance and profile control agent, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem of poor temperature resistance and salt resistance, low plugging efficiency by two-liquid method, and large-displacement horizontal well operations. High risk and other problems, to achieve the effect of excellent temperature resistance and salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

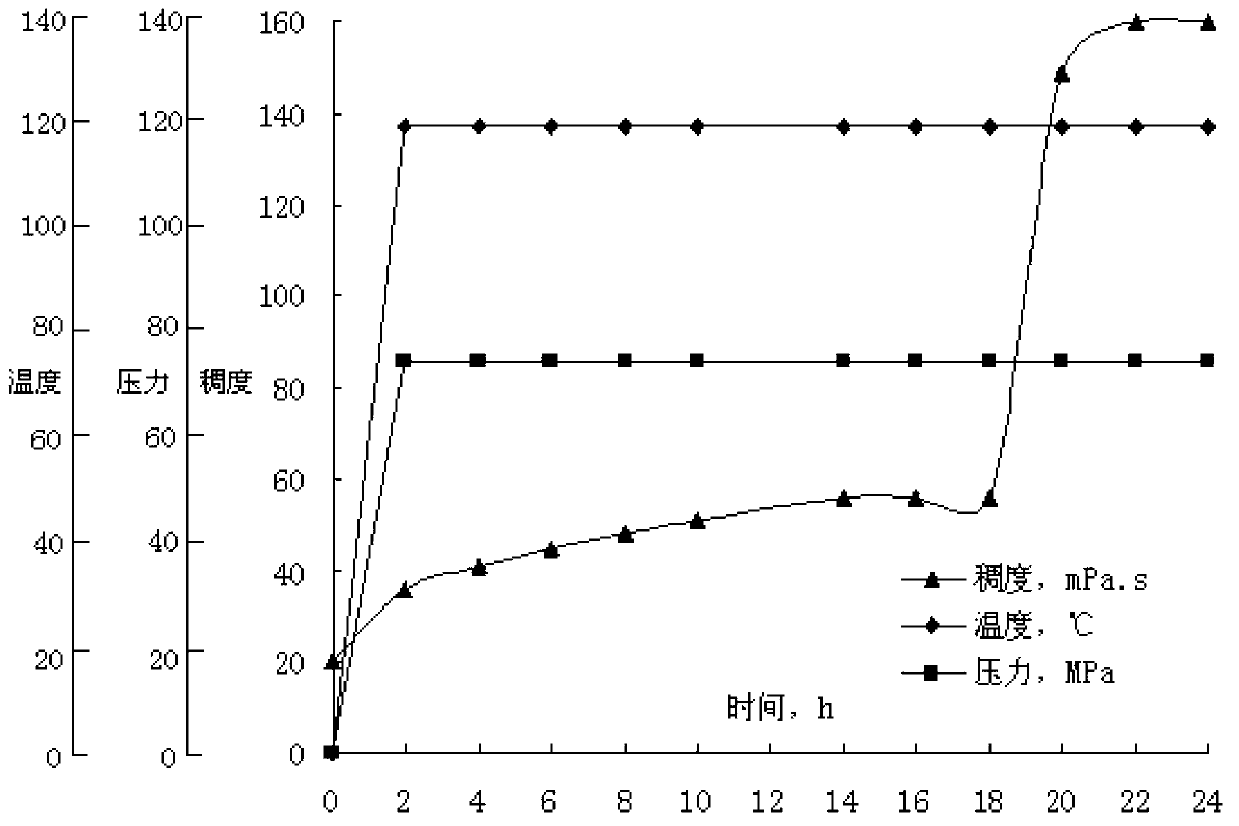

[0090] The density generated during the drilling of oil and gas wells in Tahe Oilfield was 1.30g / cm 3 1000g of waste mud (the composition of which is 0.5% crude oil and the metal ions are mainly Ca 2+ , Mg 2+ , the content is 11100mg / L, 930mg / L respectively; the organic content is 8.8%, the inorganic content is 91.2%, and the inorganic content includes debris, fine-grained calcium carbonate, iron sulfate and mineral salts. Add to the paddle mixer, take the weight of the waste mud as 100%, use 6% by weight of microsilicon as waste mud solidifying agent, 6% by weight of fly ash as strength modifier, 0.2% of sulfonated Tannin extract as dispersant, 0.15% Na 2 CO 3 As a retarder and 12% oil field treated water, it is directly added to the waste mud to make a mixed solution to obtain profile control agent 1 # , the profile control agent was placed at room temperature for 66h and no thickening phenomenon was found. The density, viscosity, static curing strength, static curing cu...

Embodiment 2

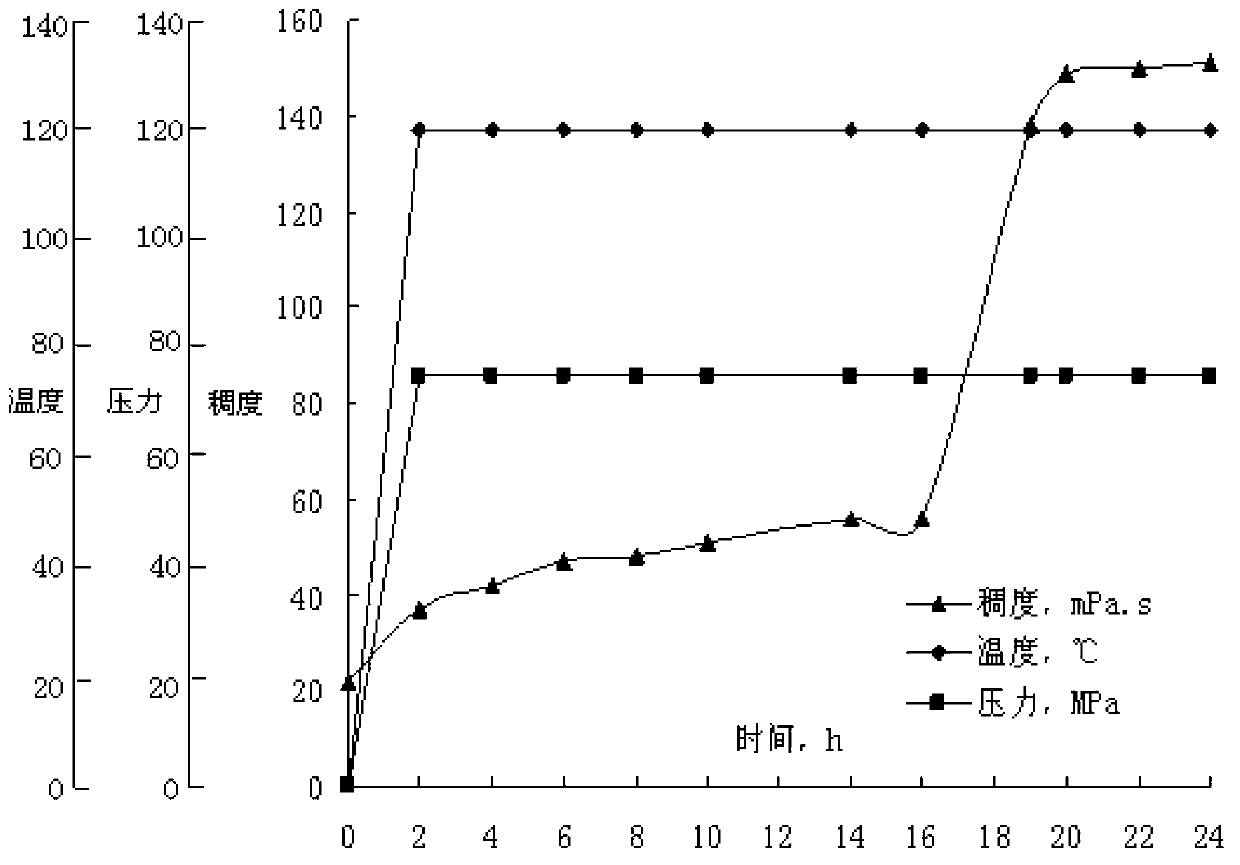

[0092] The density generated during the drilling of oil and gas wells in Tahe Oilfield was 1.32g / cm 31000g of waste mud (in which the composition is 1.5% crude oil, and the metal ions are mainly Ca 2+ , Mg 2+ , the content is 10000mg / L, 900mg / L respectively; the organic content is 7%, the inorganic content is 93%, and the inorganic content includes debris, fine-grained calcium carbonate, iron sulfate and mineral salts. Add to the paddle mixer, take the weight of the waste mud as 100%, use 8% by weight of microsilicon as waste mud solidifying agent, 8% by weight of fly ash as strength modifier, 0.5% of sulfonated Tannin extract as dispersant, 0.05% Na 2 CO 3 As a retarder and 10% oil field treated water, it is directly added to the waste mud to make a mixed solution to obtain profile control agent 2 # , the profile control agent was placed at room temperature for 70h and no thickening phenomenon was found. The density, viscosity, static curing strength, static curing curing...

Embodiment 3

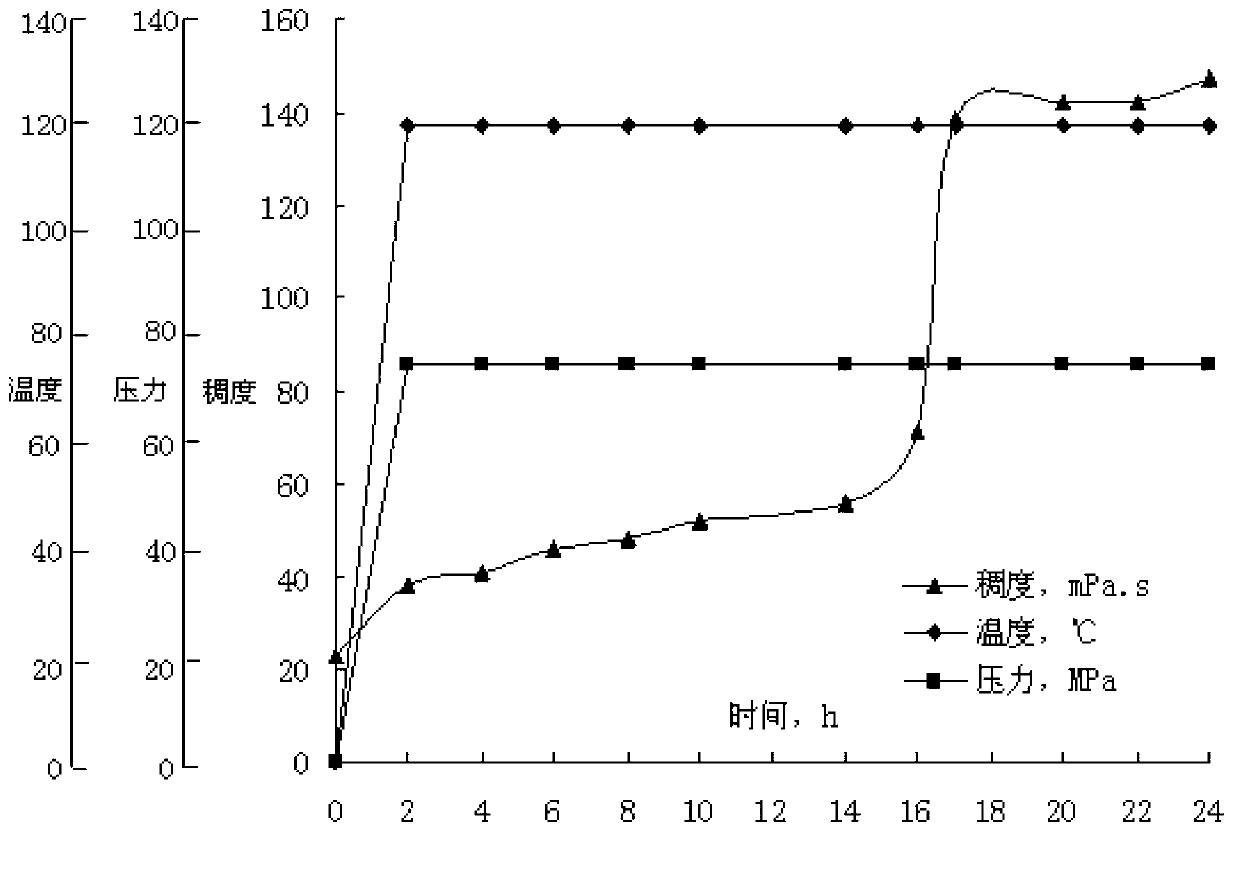

[0094] The density generated during the drilling of oil and gas wells in Tahe Oilfield was 1.35g / cm 3 1000g of waste mud (in which the composition is 1.0% crude oil, and the metal ions are mainly Ca 2+ , Mg 2+ , the content is 12000mg / L, 1000mg / L respectively; the organic content is 10%, the inorganic content is 90%, and the inorganic content includes debris, fine-grained calcium carbonate, iron sulfate and mineral salts. Add to the paddle mixer, take the weight of the waste mud as 100%, use 9% by weight of microsilicon as waste mud solidifying agent, 9% by weight of fly ash as strength modifier, 0.8% of sulfonated Tannin extract as dispersant, 0.08% Na 2 CO 3 As a retarder and 9% oil field treated water, it is directly added to the waste mud to make a mixed solution to obtain profile control agent 3 # , the profile control agent was placed at room temperature for 72h and no thickening phenomenon was found. The density, viscosity, static curing strength, static curing curi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com