Moulded-in-place high molecular thermal conductive composite material and preparation method thereof

A heat-conducting composite material and polymer technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of low temperature of heat-conducting paste and heat-conducting phase change materials, difficult to meet the use requirements, and decline in thermal conductivity. Achieve the effect of reducing application cost, safe and reliable use, and reducing thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

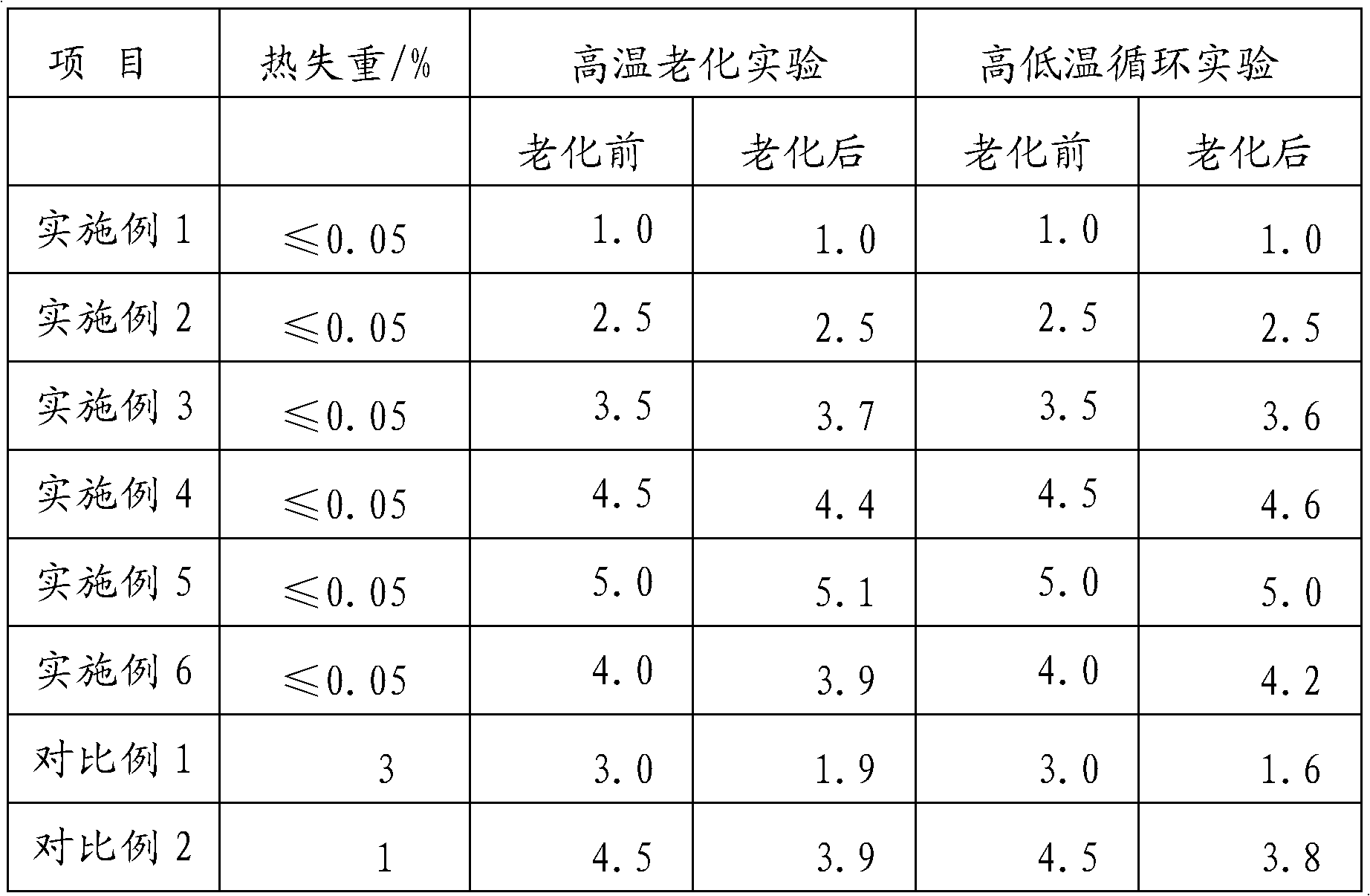

Examples

Embodiment 1

[0032] Accurately weigh 95g of silicone resin, 4g of curing agent, 0.99g of chloroplatinic acid-isopropanol complex as catalyst and 1,3,5,7-tetramethyl-1,3,5,7- Tetraethylcyclotetrasiloxane 0.01g, add the above-mentioned components into a double planetary power mixing mixer and stir for 30 minutes, add 300g of spherical A with an average particle diameter of 30 μm to the above mixture as alumina, stir for 30 minutes, and Vacuum stirring at -0.1MPa for 30 minutes to remove air bubbles;

[0033] Wherein, the silicone resin is a linear silicone resin, and its structural formula is: CH 2 =CH-Si(CH 3 ) 2 O[(CH 3 ) 2 SiO] 200 (CH 3 ) 2 Si-CH=CH 2 ; The curing agent is a hydrogen-containing silicone oil curing agent, and its structural formula is; CH 3 -Si(CH 3 ) 2 -O-[SiHCH 3 -O] 2 -[Si-(CH 3 ) 2 -O] 6 -Si(CH 3 ) 2 -CH 3 .

Embodiment 2

[0035] Accurately weigh 97g of silicone resin, 2.85g of curing agent, 0.1g of chloroplatinic acid-divinyltetramethylsiloxane complex as catalyst and 1,3,5,7-tetramethyl-1 , 0.05g of 3,5,7-tetraethylcyclotetrasiloxane, adding the above-mentioned components into a double planetary dynamic mixer and stirring for 40 minutes, adding 560g of spherical filler A with an average particle diameter of 60 μm in the above-mentioned mixture is Aluminum powder, stir for 40 minutes, add 240g of filler B with an average particle size of 10μm as copper powder, and stir in vacuum for 30 minutes under the condition of vacuum degree of -0.1MPa to remove air bubbles;

[0036] Wherein, the silicone resin is a linear silicone resin, and its structural formula is CH 2 =CH-Si(CH 3 )2 O[(CH 3 ) 2 SiO] 150 (CH 3 ) 2 Si-CH=CH 2 ; The curing agent is a hydrogen-containing silicone oil curing agent, and its structural formula is: CH 3 -Si(CH 3 ) 2 -O-[SiHCH 3 -O] 10 -[Si-(CH 3 ) 2 -O] 40 -Si(...

Embodiment 3

[0038] Accurately weigh 98g of silicone resin, 1.4g of curing agent, and 0.5g of catalyst. The catalyst is chloroplatinic acid-diethylphthalate complex, and the stabilizer is 1,3,5,7-tetramethyl Base-1,3,5,7-tetraethylcyclotetrasiloxane 0.1g, add the above components into a double planetary power mixer and stir for 50 minutes, add 770g of spherical particles with an average particle size of 40μm to the above mixture Filler A is zinc oxide, stirred for 50 minutes, added 330g of filler B with an average particle size of 5 μm, and vacuum stirred for 30 minutes under the condition of vacuum degree of -0.1MPa to remove air bubbles;

[0039] Wherein, the silicone resin is a linear silicone resin, and its structural formula is: CH 2 =CH-Si(CH 3 ) 2 O[(CH 3 ) 2 SiO] 200 (CH 3 ) 2 Si-CH=CH 2 ; The curing agent is a hydrogen-containing silicone oil curing agent, and its structural formula is: CH 3 -Si(CH 3 ) 2 -O-[SiHCH 3 -O] 30 -[Si-(CH 3 ) 2 -O] 68 -Si(CH 3 ) 2 -CH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com