Breathable water-repellent type self-adhering bandage

A self-adhesive and bandage technology, applied in bandages, medical science, clothing, etc., can solve the problems of wound infection, increase user pain, affect wound recovery, etc., and achieve the effect of easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

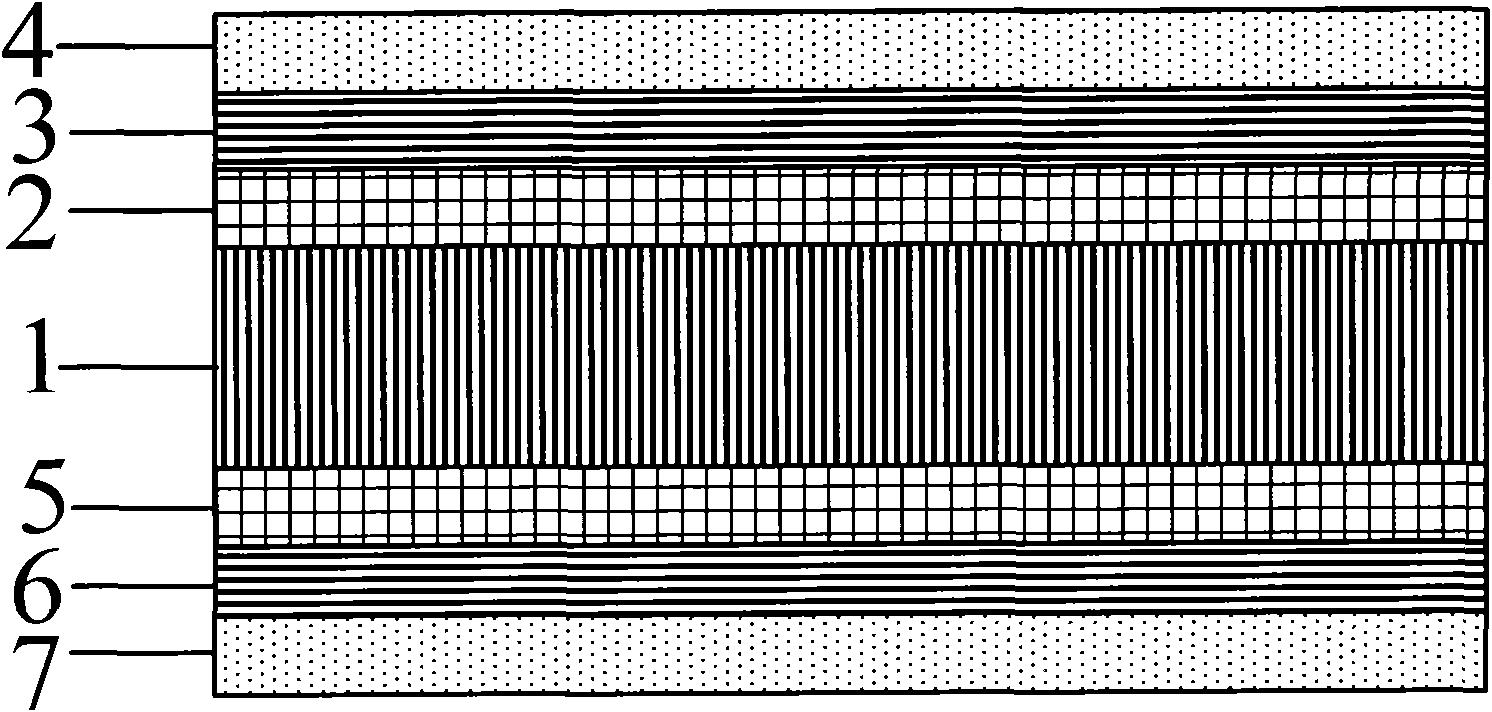

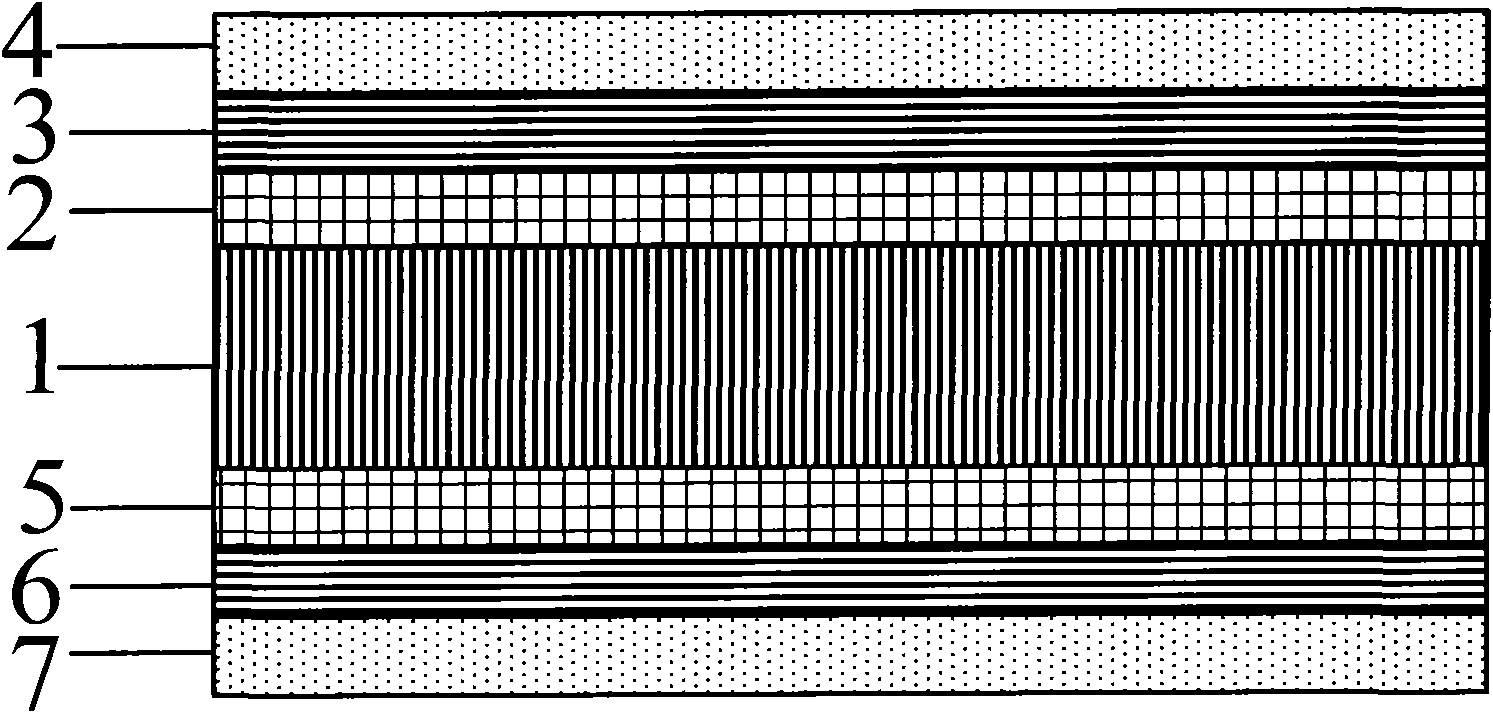

[0014] Such as figure 1 As shown in the air-permeable and water-repellent self-adhesive bandage, the substrate is polyurethane sponge 1, the front of polyurethane sponge 1 is compounded with elastic non-woven fabric 3 through composite adhesive layer 2, and the surface of elastic non-woven fabric 3 is coated with self-adhesive adhesive layer 4 The back of the polyurethane sponge 1 is also composited with an elastic non-woven fabric 6 through a composite adhesive layer 5, and the surface of the elastic non-woven fabric 6 is coated with a self-adhesive adhesive layer 7. Among them, the density of polyurethane sponge 1 is 28~50kg / m 3 , the thickness is 0.6 ~ 4.5mm. The elastic nonwoven fabric 3 and the elastic nonwoven fabric 6 have a thickness of 0.2-0.4 mm.

[0015] The composite adhesive layer 2 and the composite adhesive layer 5 are rubber-based adhesives or acrylic-based adhesives or polysiloxane-based adhesives or polyurethane-based adhesives. Usually, the rubber-based a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com