Hernia mesh and preparation method thereof

一种补片、填料筒的技术,应用在医疗用品领域,能够解决技术标准没有得到很好的定义等问题,达到避免人体不良反应、确保稳固性、异物残留少的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

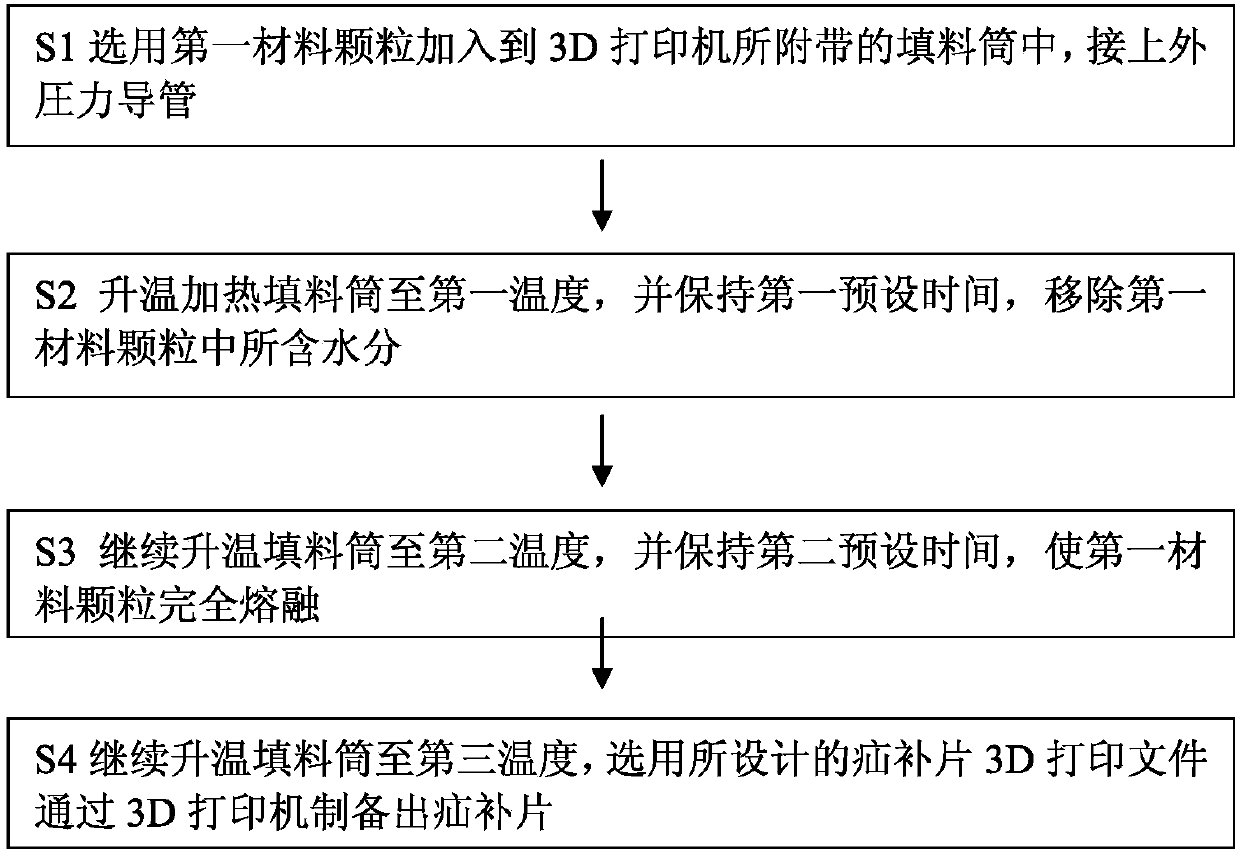

[0044] The invention provides a convenient and fast method for preparing hernia mesh, enabling doctors to customize the most suitable hernia mesh in a short time according to the needs of patients' conditions. figure 1 Shows a flow chart of the steps of Embodiment 1 of the present invention, as figure 1 As shown, Embodiment 1 of the present invention includes the following steps,

[0045] S1 selects the first material particles and adds them to the packing tube attached to the 3D printer, and connects the external pressure conduit.

[0046] In this step, in order to make the hernia patch material have better biocompatibility, the first material is a biodegradable material, specifically, it can be polylactic acid and polycarbonate copolymer (copolymer of polylactide andpolytrimethylene carbonate), One or more of poly-4-hydroxybutyrate copolymer (copolymer of Poly-4-hydroxybutyrate), polylactic acid (PLA), 3-hydroxybutyrate and 3-hydroxyvalerate copolymer (PHBV) kind. In this...

Embodiment 2

[0066] In order to improve the biocompatibility and maintain the strength and rigidity of the hernia patch in the early stage, it can still maintain a certain supporting force and be absorbed by the human body during the healing period of the surgical wound. The second embodiment of the present invention has developed a Hernia mesh with core-shell structure.

[0067] Such as Image 6 Shown, embodiment two comprises the following steps,

[0068] S1 selects the first material particles and adds them to the packing tube attached to the 3D printer, and connects the external pressure conduit.

[0069] In this step, in order to reduce the stiffness of the hernia mesh to 70% of the initial stiffness during the healing period of the surgical wound, and at the same time improve the flexibility and softness of the remaining hernia mesh after the degradation of the shell material, the one with a longer degradation time is selected. A biodegradable polymer (for 36 months) is the core la...

Embodiment 3

[0082] Embodiment 3 of the present invention also provides a hernia patch prepared by the above method, such as Figure 7As shown, the hernia mesh provided by Embodiment 3 of the present invention includes a mesh body 1 and a plurality of hook bodies 2 fixedly connected to grid intersections of the mesh body 1 . The patch body 1 is used to sew the hernia gap, which can block the pressure of the abdominal wall, so that the hernia gap can withstand greater pressure and tensile force; multiple hook bodies 2 are used to fix the patch body 1 at the hernia gap. It can effectively connect the hernia mesh with the body, prevent the hernia mesh from moving or twisting during human movement, and avoid the use of additional metal or plastic rivets to fix the hernia mesh in the body, eliminating the need for mechanical The adverse reaction of the human body caused by the fixed method greatly increases the comfort of the patient. In order to ensure that the properties of each hernia patch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com