Polyethylene-based thermoplastic elastomer and preparation method and composite plastic thereof

A thermoplastic elastomer, polyethylene-based technology, applied in the field of polyethylene-based thermoplastic elastomers and their preparation, thermoplastic composite plastics, can solve problems affecting the mechanical properties and flow properties of matrix materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

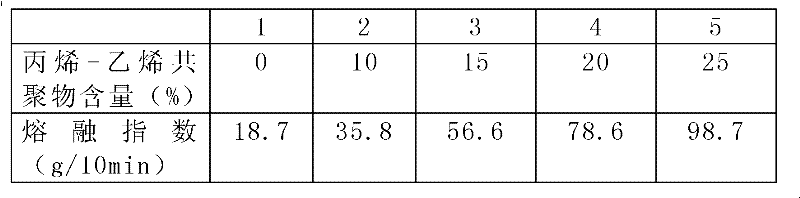

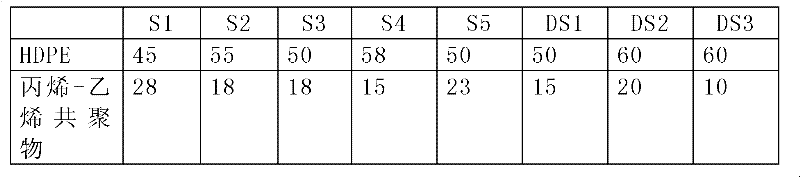

[0054] 45kg HDPE, 28kg propylene-ethylene copolymer (ethylene content 20wt%), 15kg EVA (vinyl acetate content 25wt%), 4kg silicone flame retardant, 6kg ammonium polyphosphate, 1kg calcium carbonate and 0.5kg antioxidant, 0.5 kg ultraviolet absorber is put into the mixer together and mixed evenly, then transferred to a high-speed co-rotating parallel twin-screw extruder to extrude strands and cut pellets. The extrusion process conditions are shown in Table 3 below:

[0055] table 3

[0056]

[0057] Through the above-mentioned steps, the polyethylene-based thermoplastic elastomer blank of this embodiment was obtained, and after heat treatment at 80° C., the finished polyethylene-based thermoplastic elastomer was obtained, denoted as S1.

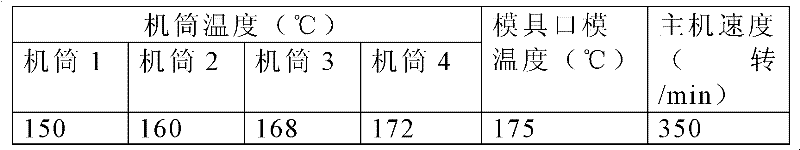

Embodiment 2-5

[0059] Polyethylene-based thermoplastic elastomers S2-S5 were prepared in the same steps as in Example 1. The difference is that the content of each component is shown in Table 4 below: S2 heat treatment temperature is 90 ° C, S2 heat treatment temperature is 100 ° C, S4 heat treatment The temperature is 90°C, the S4 heat treatment temperature is 90°C, and the S5 heat treatment temperature is 90°C.

[0060] Table 4

[0061]

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com