Vibration damper composition

A composition and polymer technology, applied in the direction of non-rotational vibration suppression, film/sheet adhesive, other chemical processes, etc., can solve problems such as not easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0120] Preparation Example 1: Preparation of Diblock Copolymers Containing Polystyrene Blocks and Polyisobutylene Blocks

[0121] Into a 2 L reactor equipped with a stirrer were charged 589 mL of methylcyclohexane (previously dried over molecular sieves), 613 mL of n-butyl chloride (previously dried over molecular sieves) and 0.550 g of cumyl chloride. After cooling the reactor to -70°C, 0.35 ml of α-picoline (2-picoline) and 179 ml of isobutene were added. Then 9.4 ml of titanium tetrachloride was further added, whereby polymerization was started. The reaction was carried out at -70°C for 2.0 hours under constant stirring. To the reaction mixture was added 59 ml of styrene and further reacted for 60 minutes, at the end of which a large amount of methanol was added to stop the reaction. The solvent was removed from the reaction mixture and the polymer was dissolved in toluene and washed with 2 portions of water. The washed toluene solution was poured into methanol to precip...

preparation Embodiment 2

[0123] Preparation Example 2: Preparation of a tri-block copolymer containing polystyrene block-polyisobutylene block-polystyrene block

[0124] A 2 L reactor equipped with a stirrer was charged with 570 ml of methylcyclohexane (previously dried over molecular sieves), 590 ml of n-butyl chloride (previously dried over molecular sieves) and 0.400 g of dicumyl chloride. After cooling the reactor to -70°C, 0.34 ml of α-picoline (2-picoline) and 174 ml of isobutene were added. Then 10.3 ml of titanium tetrachloride was further added, whereby polymerization was started. The reaction was carried out at -70°C for 2.0 hours under constant stirring. To the reaction mixture was added 58 ml of styrene and further reacted for 60 minutes, at the end of which a large amount of methanol was added to stop the reaction. The solvent was removed from the reaction mixture and the polymer was dissolved in toluene and washed with 2 portions of water. The washed toluene solution was poured into m...

Embodiment 1~8 and comparative example 1~7

[0127] According to the formula shown in Table 1, the block copolymer (A) (SIB-1 prepared in Preparation Example 1), thermoplastic elastomer, thermoplastic resin, tackifying resin and plasticizer were kneaded together, using Labo- Plastomill (manufactured by Toyo Precision Machinery) was kneaded at 170° C. for 15 minutes to produce a rubber composition. The rubber compositions were each compression molded at 170°C to prepare sheets. Moldability is good. A 5 mm x 6 mm x 1.7 mm sample was cut from each sheet.

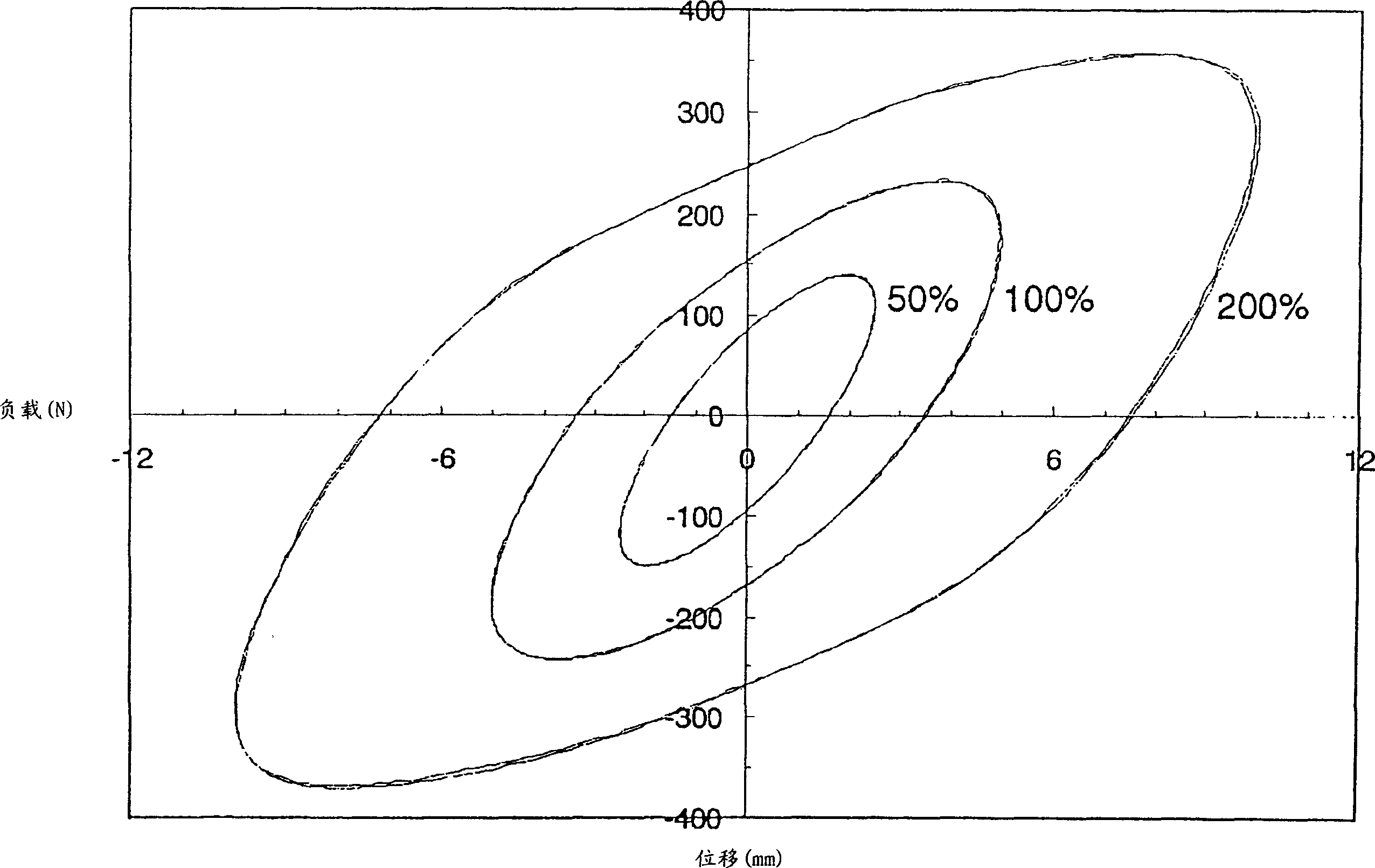

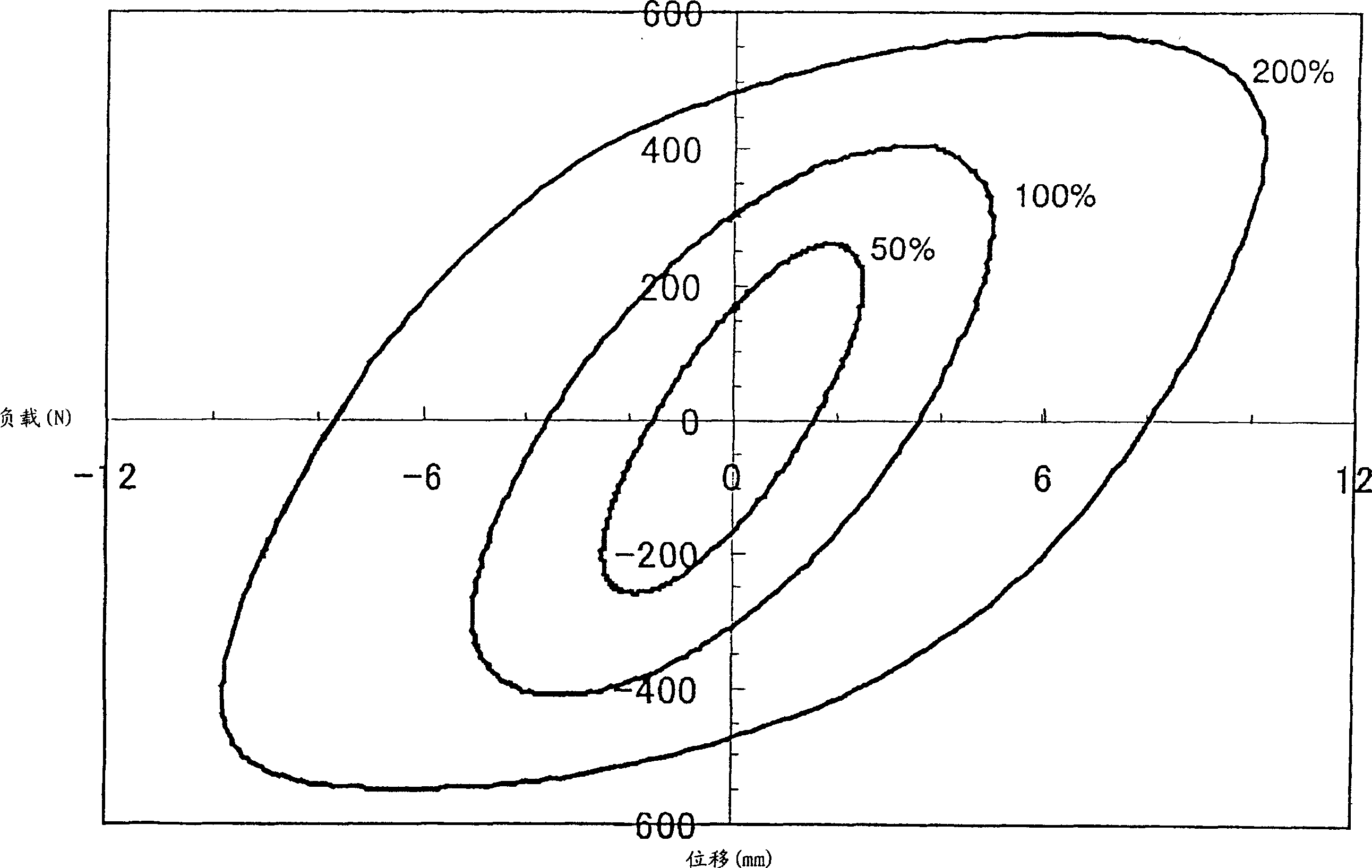

[0128] Measurement of Dynamic Viscoelasticity

[0129] Using two samples per group, the dynamic viscoelasticity of each composition was measured at a frequency of 0.5 Hz and a shear strain of 0.05% in accordance with JIS K-6394. As an instrument for measurement, a dynamic viscoelasticity meter DVA-200 (manufactured by ITMetric Control) can be used. Regarding the storage modulus (G'), the (G') value at 0°C can be calculated (G' 0℃ ) and (G') value at 40°C (G' 40℃ ) r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com