Hydrogen-sensitive discoloration detection adhesive tape, and preparation method and application thereof

A technology of adhesive tape and color-changing materials, which is applied in the direction of detecting the appearance of fluid, adhesives, and measuring devices at the leakage point, can solve the problems of limited positioning ability, affecting the detection sensitivity of sensors, and limited, etc., to achieve a simple and intuitive way of expression, high Promote the use value and improve the effect of rescue speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

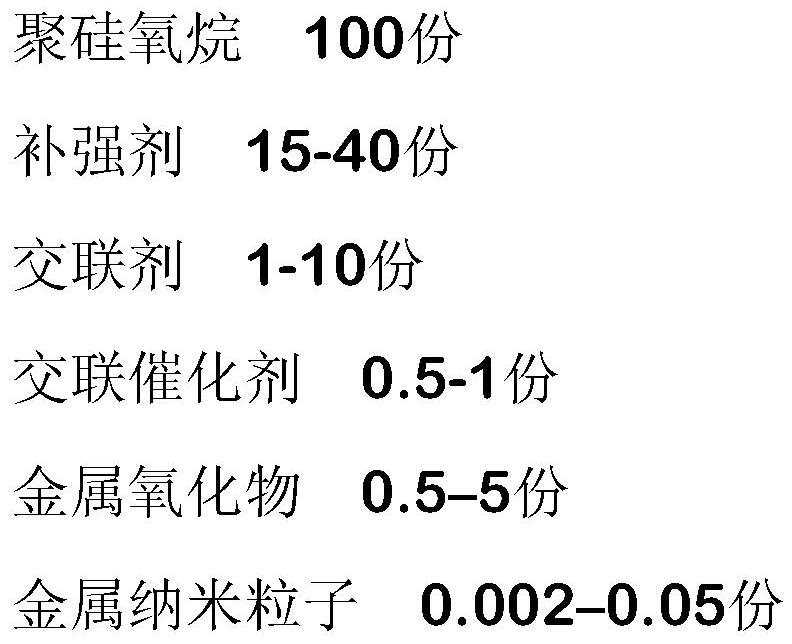

Embodiment 1

[0056] Weigh 100 parts by weight of hydroxyl-terminated polysiloxane, add 32 parts by weight of fumed silica reinforcing agent to a kneader, and stir evenly at room temperature to obtain a tape matrix. Then add 1.5 parts by weight of tungsten oxide and 0.005 parts by weight of platinum nanoparticles to make the adhesive tape have a color-changing function. 3 parts by weight of tetraethyl orthosilicate crosslinking agent and 0.5 part by weight of dioctyltin dilaurate are added to make the adhesive tape have self-adhesive function. Then use a kneader to knead and mix. Immediately after mixing, make a strip-shaped sheet with a width of 5 cm and a thickness of 0.5 mm by mechanical external force, attach a plastic backing paper, and make a tape roll or tape strip semi-finished product. Then put the semi-finished product at room temperature for about 12 hours to cure, and the cured adhesive tape is the hydrogen-sensitive discoloration detection adhesive tape.

[0057] When in use, ...

Embodiment 2

[0060] Weigh 100 parts by weight of hydroxyl-terminated polysiloxane, and add 25 parts by weight of fumed silica reinforcing agent to a kneader. Then 2.5 parts by weight of palladium oxide, 0.01 part by weight of nickel nanoparticles, 5 parts by weight of methyltributylketoximosilane crosslinking agent, and 0.5 parts by weight of tetrabutyl titanate were added. Then use a kneader to knead and mix at room temperature. Immediately after mixing, make a strip-shaped sheet with a width of 2 cm and a thickness of 0.2 mm, attach a plastic backing paper, and make a tape roll or tape strip semi-finished product. Then put the semi-finished product at room temperature for about 12 hours to cure, and the cured adhesive tape is the hydrogen-sensitive discoloration detection adhesive tape.

[0061] When in use, tear off the backing paper of the tape, wrap the tape around the leak point of the pre-made pipeline, and use the self-adhesive property of the tape to fix the tape. If a mixture of...

Embodiment 3

[0063] Weigh 100 parts by weight of hydroxyl-terminated polysiloxane, and add 15 parts by weight of fumed silica reinforcing agent to a kneader. Then add 1 weight part of molybdenum oxide and 0.008 weight part of nickel nanoparticles to make the adhesive tape have a color-changing function. 10 parts by weight of methyl tributylketoxime silane crosslinking agent and 0.8 parts by weight of dibutyl tin dioctoate were added. Use a kneader to knead and mix. Immediately after mixing, make a strip-shaped sheet with a width of 10cm and a thickness of 0.2mm by mechanical external force, attach a plastic backing paper, and make a tape roll or tape strip semi-finished product. Then put the semi-finished product at room temperature for about 10 hours to cure, and the cured adhesive tape is the hydrogen-sensitive discoloration detection adhesive tape.

[0064] When in use, tear off the backing paper of the tape, wrap the tape around the leak point of the pre-made pipeline, and use the sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com