Fireproof insulating layer for cryogenic storage tank

An insulating layer, cryogenic technology, used in fixed-capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc., can solve problems such as medium explosion, danger, and easy combustion, reducing usage and low cost , the effect of improving fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

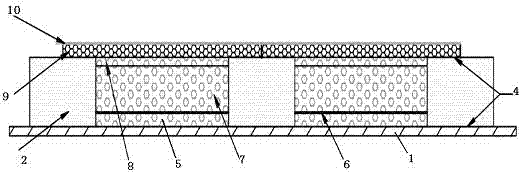

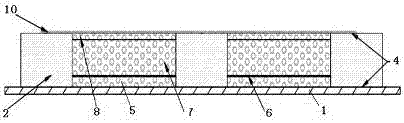

[0020] Such as figure 1 As shown, a kind of cryogenic storage tank fireproof insulating layer disclosed by the present invention comprises cryogenic storage tank 1, a plurality of prefabricated foam blocks 2, spray foam, injection molding foam and foam glass, and a plurality of prefabricated foam blocks 2 pass cryogenic Glue 4 is bonded to the surface of the cryogenic storage tank 1 at horizontal and vertical intervals, and the surface of the cryogenic storage tank between the prefabricated foam blocks is sequentially bonded with the first layer of injection foam 5, the anti-crack layer 6, and the second layer of injection molding. Foam 7 and spray foam 8, and spray foam is sprayed on the surface layer of injection foam, foam glass is bonded on the prefabricated foam block and spray f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com