Flame-retardant and heat-resistant epoxy resin for self-adhesive prepreg

A technology of epoxy resin and phenolic epoxy resin, applied in the field of prepreg manufacturing, can solve problems such as reducing heat resistance, and achieve the effects of reducing production cost, simplifying process and short curing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The above-mentioned preparation method of flame-retardant and heat-resistant epoxy resin for self-adhesive prepreg comprises the following steps:

[0042] (1) Prepare the raw materials respectively according to the formula amounts of the epoxy resin mixture A component and the curing agent mixture B component; prepare the mixing equipment;

[0043] (2) prepare epoxy resin mixture A component and curing agent mixture B component respectively;

[0044] ① Epoxy resin mixture A component

[0045] a. Add the component A of the epoxy resin mixture into the mixing equipment and mix thoroughly until it is uniform;

[0046] b. Pour the mixed epoxy resin mixture component A into the product barrel, seal it, protect it from light, and store it at room temperature;

[0047] ②The curing agent mixture B component

[0048] Mix the B component of the curing agent mixture, and pulverize it to a particle size of 50-100 meshes with a pulverizing equipment;

[0049](3) Preparation of f...

Embodiment 1

[0052] Raw materials of component A of epoxy resin mixture: bisphenol A epoxy resin E-54---60 parts; glycidylamine tetrafunctional epoxy resin AG-80---10 parts; polyethersulfone (PES) ---10 parts; Bromobisphenol S---15 parts

[0053] Raw materials of component B of curing agent mixture: modified dicyandiamide---10 parts; modified urea---2 parts; aluminum oxide---2 parts

[0054] Preparation method: Add component A of epoxy resin mixture to mixing equipment and mix evenly. Mix the B component of the curing agent mixture, and pulverize it to a particle size of 50-100 meshes with a pulverizing equipment;

[0055] Add the component A of the epoxy resin mixture to the mixing equipment, heat it to 60-90 ° C, keep the temperature for 0.5-1 hour, add the component B of the curing agent mixture to the component A of the epoxy resin mixture, and mix well.

[0056] Self-adhesive glass cloth prepreg can be prepared by impregnating EW250F glass cloth with a hot melt prepreg machine. The...

Embodiment 2

[0059] Raw materials of component A of epoxy resin mixture: bisphenol A epoxy resin E-51---50 parts; glycidyl ester trifunctional epoxy resin TDE-85---10 parts; polysulfone (PS)- --10 parts; Tetrabromobisphenol A---10 parts;

[0060] Raw materials of component B of curing agent mixture: dicyandiamide---10 parts; modified urea---2 parts; flame retardant auxiliary aluminum hydroxide---10 parts

[0061] The preparation methods of epoxy resin, prepreg and composite material are the same as those in Example 1.

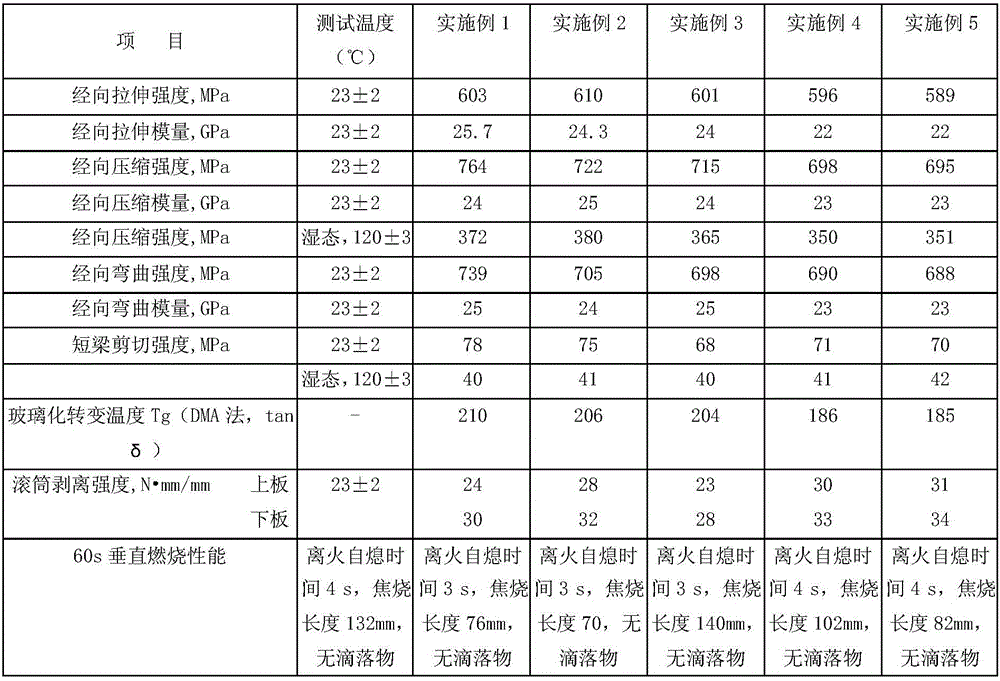

[0062] The test results of the composite materials are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com