Nano composite hydrogel and preparation method and application thereof

A nanocomposite and hydrogel technology, applied in the field of hydrogel, can solve the problems of low mechanical strength and insufficient toughness of composite hydrogel, achieve injectability, increase mechanical strength and toughness, and improve storage modulus Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

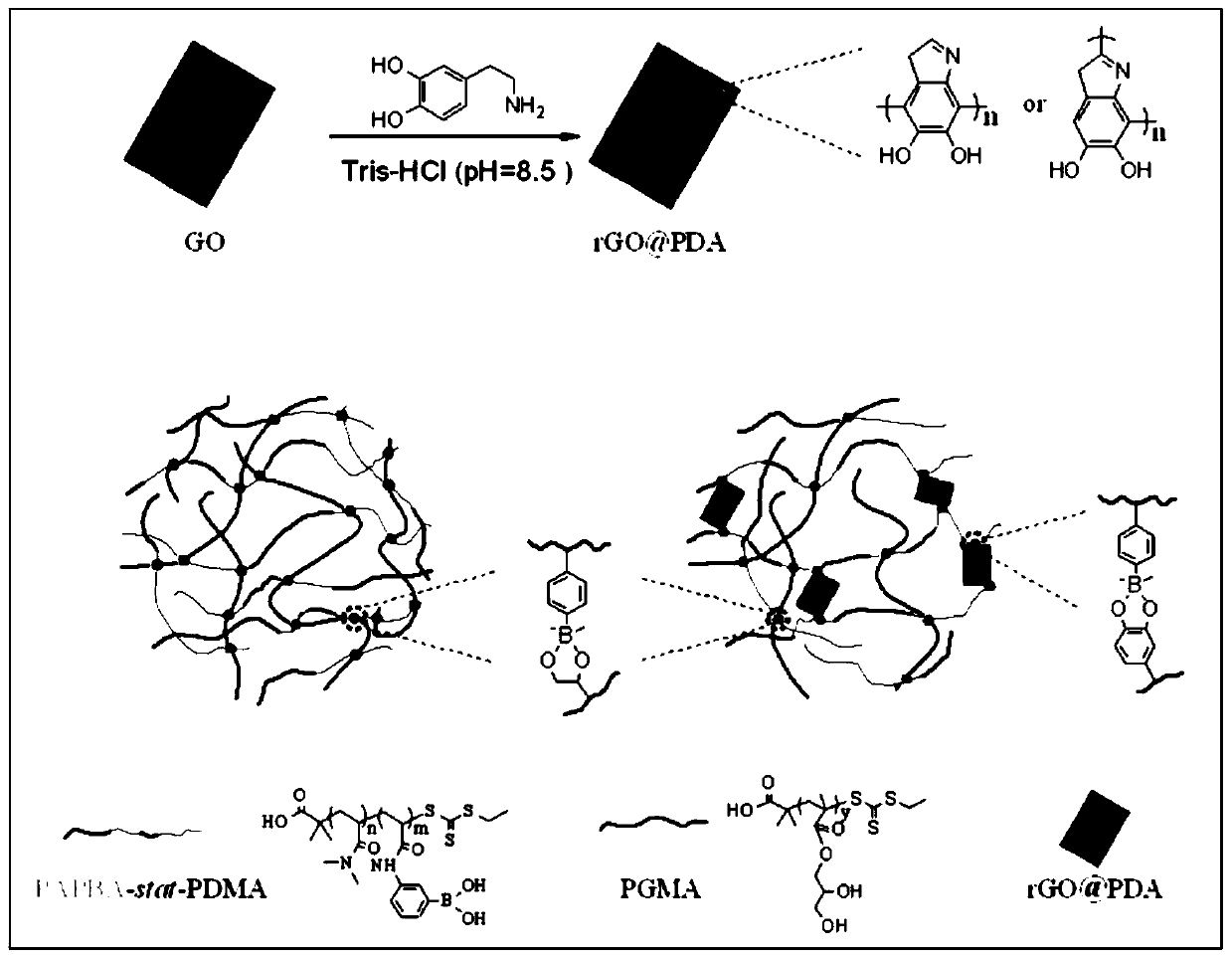

[0071] A method for preparing a nanocomposite hydrogel or a method for preparing a nanocomposite hydrogel described in the first embodiment, the method comprises the following steps:

[0072] (1) Synthesis of a polymer containing phenylboronic acid: dissolve the substance containing phenylboronic acid in a solvent, add a chain transfer agent and an initiator, and react to obtain a polymer containing phenylboronic acid;

[0073] (2) Synthesis of polymers containing diols: Dissolving substances containing 1,2-diols or 1,3-diols in solvents, adding chain transfer agents and initiators, and reacting to obtain diol-containing polymers polymer;

[0074] (3) Synthesis of polydopamine-coated and modified nanoparticles: disperse the nanoparticles in a buffer solution, add dopamine, stir and react for a period of time, separate the solid, and obtain polydopamine-coated and modified nanoparticles;

[0075] (4) Preparation of nanocomposite hydrogel: dissolve the polydopamine-coated and m...

Embodiment 2

[0077] A method for preparing a nanocomposite hydrogel with pH response, self-healing, self-adhesive and injectable properties, the method comprising the following steps:

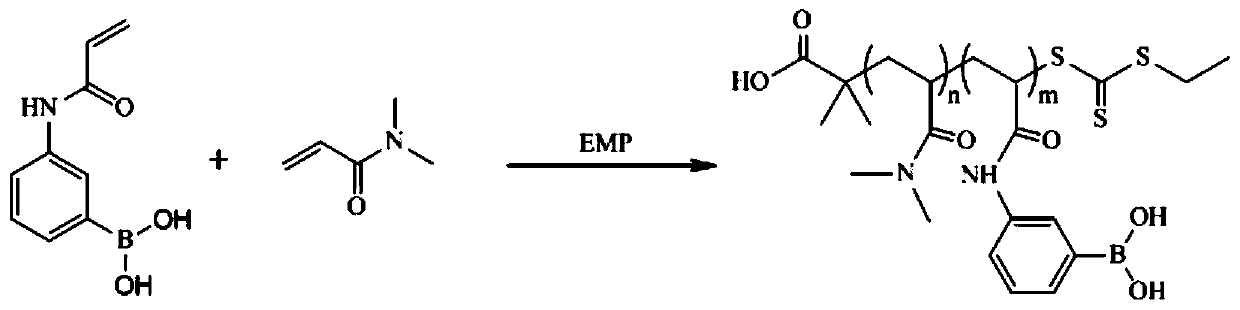

[0078] (1) Synthesis of polymers containing phenylboronic acid: APBA and GMA monomers, DMF and H 2 The mixed solvent of O, the chain transfer agent EMP and the initiator AIBN are added to the round bottom flask, and the round bottom flask is sealed after blowing nitrogen and deoxygenating, and reacted at a constant temperature in an oil bath. After a period of time, liquid nitrogen is quenched to stop the reaction. DMF was diluted and settled with ether, and the obtained product was vacuum-dried at room temperature;

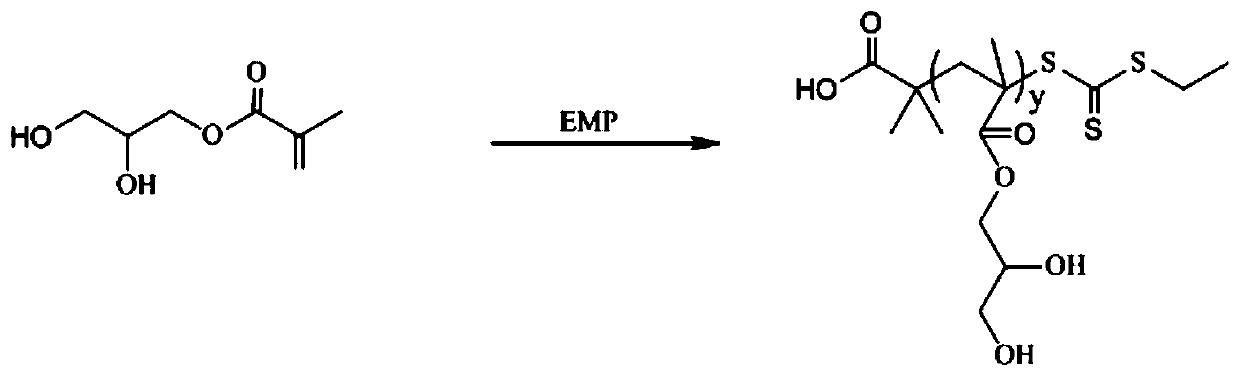

[0079] (2) Synthesis of polymers containing diols: GMA monomer, chain transfer agent EMP, initiator AIBN and solvent DMF are added to the round-bottomed flask, and the round-bottomed flask is sealed after blowing nitrogen and oxygen, and placed in an oil bath Constant temperature reaction, af...

Embodiment 3

[0083] A method for preparing a nanocomposite hydrogel with pH response, self-healing, self-adhesive and injectable properties, the method comprising the following steps:

[0084] (1) PAPBA-stat-PDMA synthesis: 90mg EMP (0.4mmol RAFT group), DMA (3.172g, 32mmol), APBA (1.528g, 8mmol), AIBN (6.56mg, 0.04mmol), 19mL fresh DMF and 1mL H 2 O was added to a dry round-bottomed flask; nitrogen was blown in to vent the oxygen in the reactor, the flask was sealed, and then immersed in an oil bath at 70°C; after 2 hours, the polymerization reaction was terminated by liquid nitrogen; after cooling to room temperature, the polymerization The substance is diluted with DMF; the polymer is precipitated in anhydrous ether to obtain a polymer containing phenylboronic acid;

[0085] (2) PGMA synthesis: put 45.0mg EMP (0.2mmol RAFT group), GMA (3.2g, 20mmol), AIBN (3.28mg, 0.02mmol), 16mL fresh DMF into a dry round bottom flask; blow nitrogen , the oxygen in the reactor was vented, the flask wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com