Apparatus and method for transforming solid waste into useful products

a technology of solid waste and products, applied in the direction of grain treatment, manufacturing tools, packaging goods, etc., can solve the problems of destroying the useful hemicellulose component of woody cellulose materials contained in solid waste, destroying the modern day landfill system, and flat abrasive surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

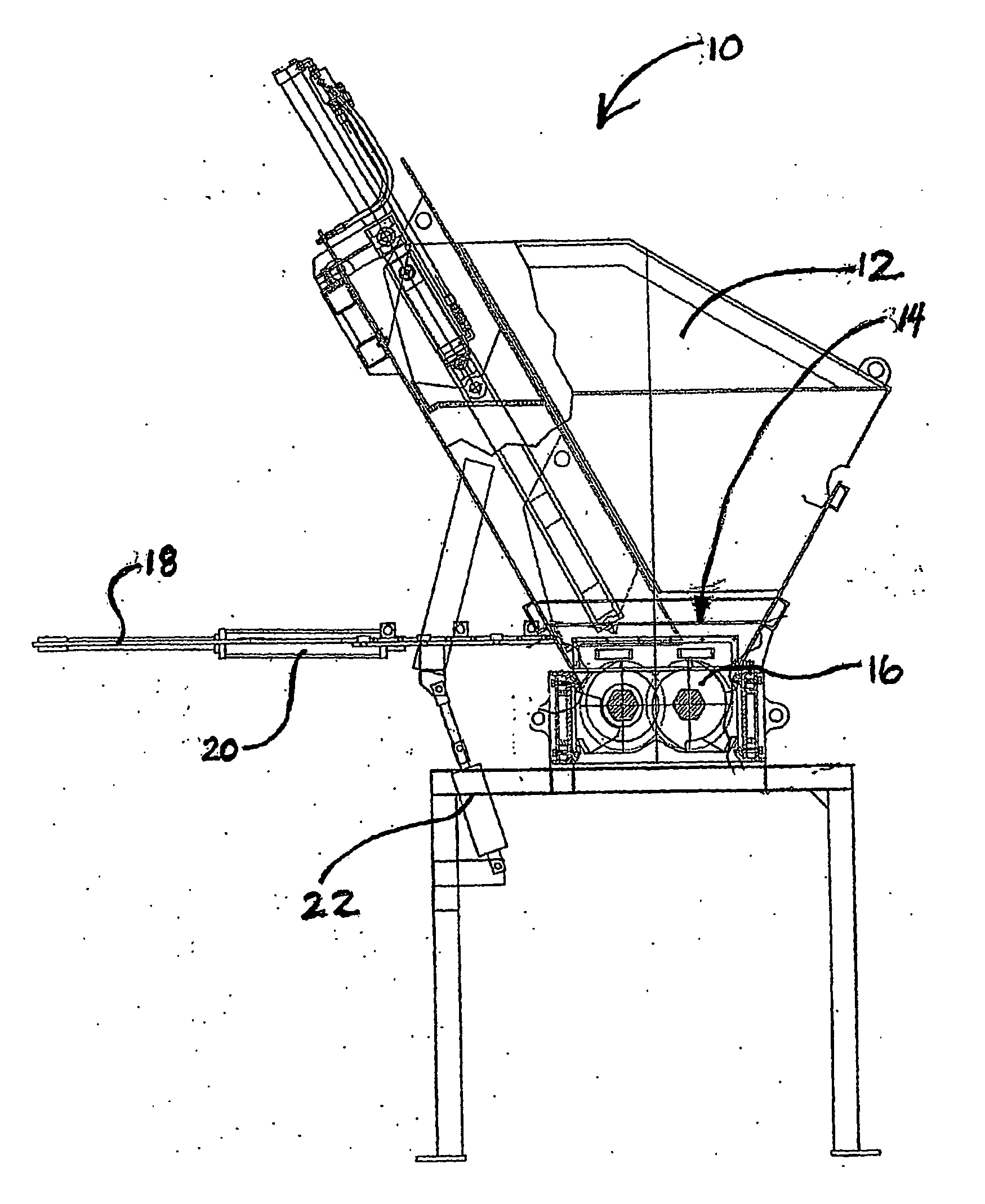

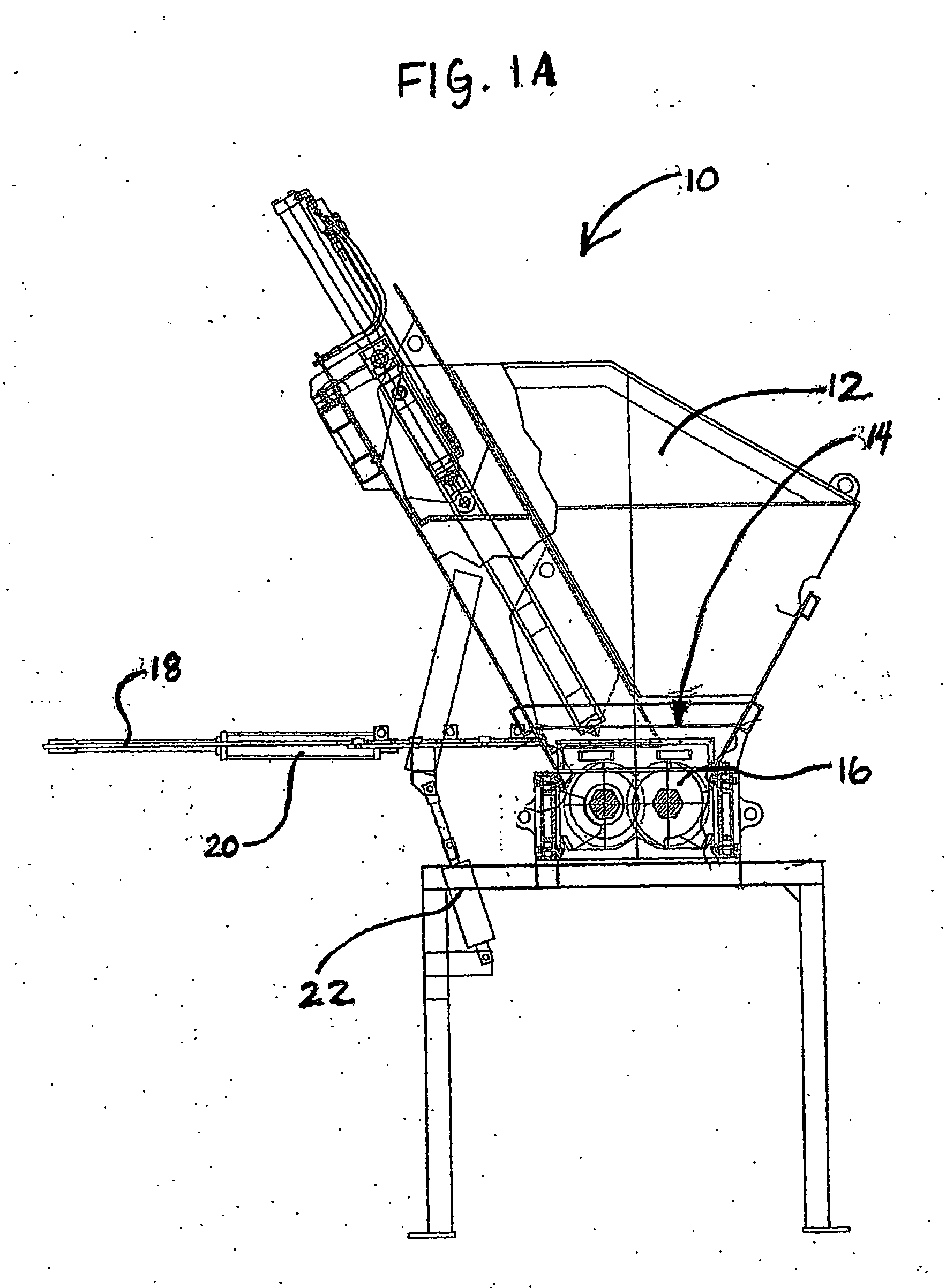

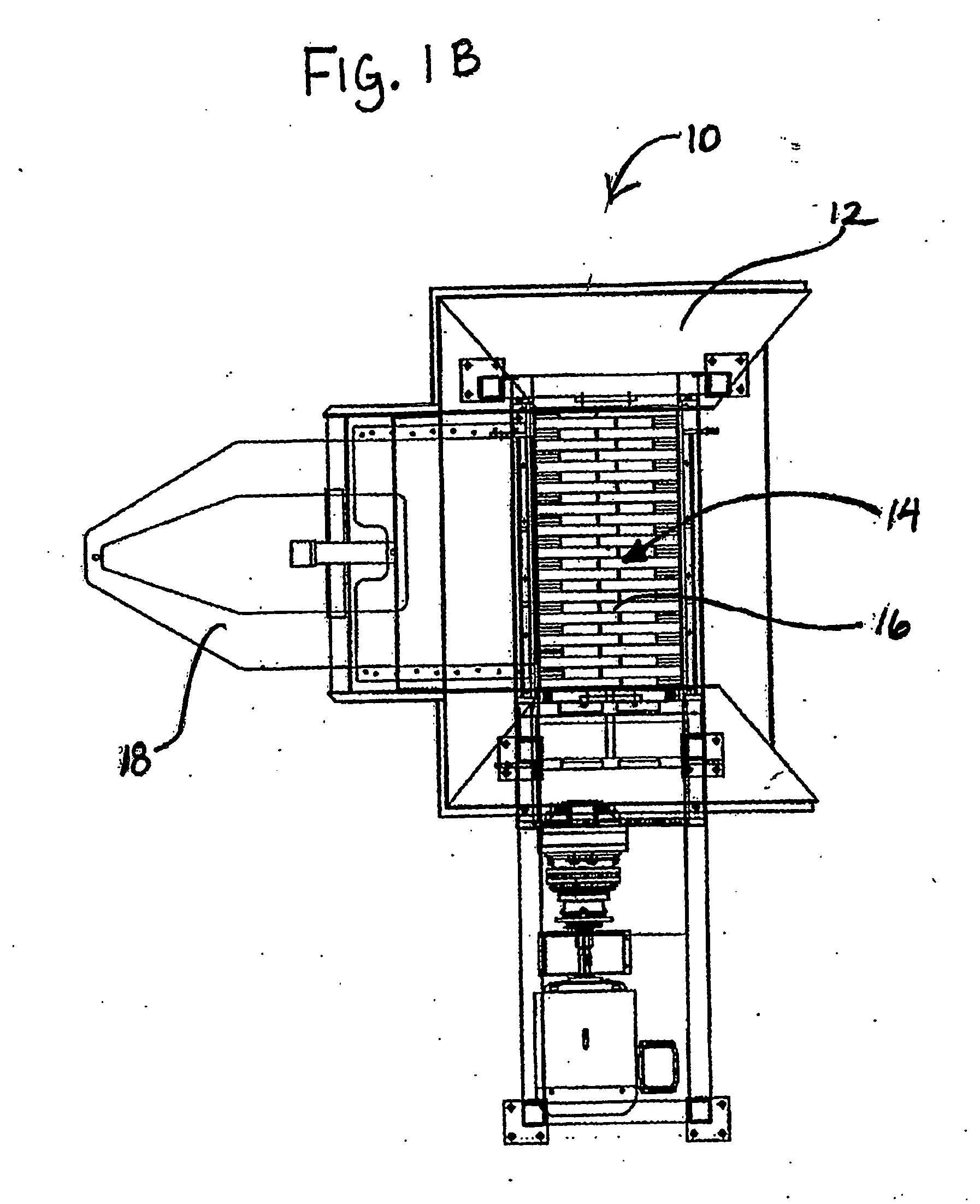

[0066] The present invention relates to solid waste disposal and includes apparatuses, systems, and methods for transforming solid waste into useful material.

[0067] Embodiment of the apparatuses of the present invention, which may be combined to create an embodiment of a system for transforming solid waste into useful material, may comprise the following: apparatuses to reduce the particle size of the waste (e.g., hammer mills, grinders, shredders); apparatuses to quickly remove objects which cannot be processed by the particle size reducing apparatuses (e.g., a hinged hopper assembly); apparatuses to remove metal (e.g., magnetic separators); apparatuses to separate components of the waste based on weight or size; apparatuses for transferring preprocessed waste material (e.g., a material injection assembly); apparatuses for decomposing the waste material (e.g., a hydrolyzer); apparatuses for transferring material from a hydrolyzer (e.g., a processed material handling apparatus); an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com