A waterproof and flame-retardant corrugated box and its production process

A corrugated box and corrugated paper technology, which is applied in the field of waterproof and flame-retardant corrugated box and its production technology, can solve the problems of major fire safety hazards, etc., and achieve the effects of improving mechanical properties, good waterproof performance, and improving hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

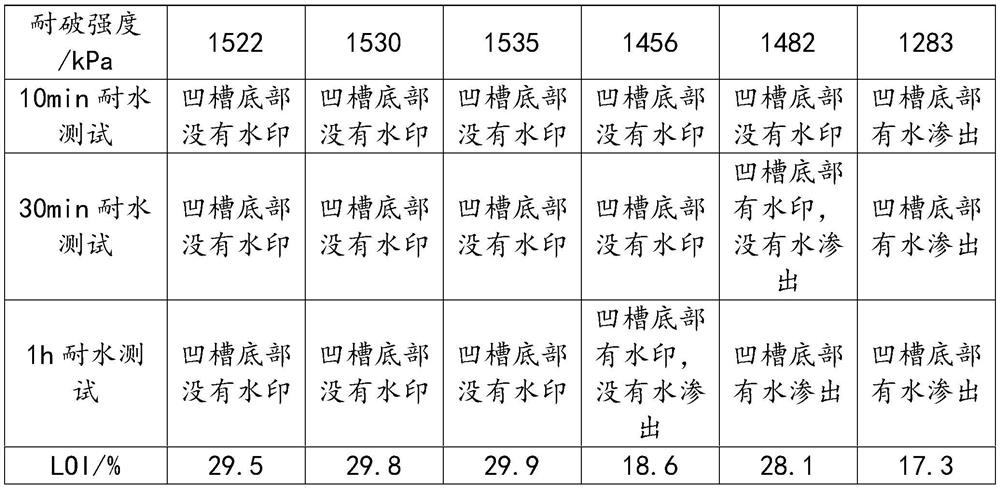

Examples

Embodiment 1

[0049] The dipping solution is prepared by the following method:

[0050] Slowly add the silica sol to the NaOH solution (30% by mass fraction) at a constant temperature of 75°C and 80r / min magnetic stirring, stir magnetically for 50min after the addition, and then add methyl cellulose and nano-TiO 2 , and continue to stir for 30 minutes to obtain an impregnation solution;

[0051] Silica sol, NaOH solution, methyl cellulose and nano TiO 2 The dosage ratio is 10:2:0.5:0.2.

Embodiment 2

[0053] The dipping solution is prepared by the following method:

[0054] Slowly add the silica sol to the NaOH solution (30% by mass fraction) at a constant temperature of 75°C and 90r / min magnetic stirring, and stir magnetically for 60 minutes after the addition, then add methyl cellulose and nano-TiO 2 , and continue to stir for 40 minutes to obtain an impregnating solution;

[0055] Silica sol, NaOH solution, methyl cellulose and nano TiO 2 The dosage ratio is 10:2:0.5:0.2.

Embodiment 3

[0057] Coatings used for functional coatings are prepared by the following methods:

[0058] (1) Add polychirolactone polyol and succinic anhydride in a three-necked flask, then add an appropriate amount of organotin catalyst, react at room temperature for 24 hours, then add N-aminoethyl-3-aminopropyltriethoxysilane, and add High temperature to 75°C, react for 10h to prepare modified polyurethane resin;

[0059] Wherein, the ratio of the amount of substances used in polychirolactone polyol and succinic anhydride is 1.2:1; the addition amount of N-aminoethyl-3-aminopropyltriethoxysilane and organotin catalyst is respectively 4% and 0.1% of mass;

[0060] (2) adding the modified polyurethane resin into an aqueous solution of acetic acid with a mass fraction of 5%, then adding a small amount of methanol, and magnetically stirring for 3 hours to obtain a modified polyurethane emulsion;

[0061] The mass ratio that modified polyurethane resin, acetic acid aqueous solution and met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| edge compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com