Coated controlled-release fertilizer for modifying urea into easily degradable film and production method of coated controlled-release fertilizer

A controlled-release fertilizer and easy-to-degrade technology, which is applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of large-scale popularization and application limitations, long degradation cycle of residual film, etc., and achieve sustainable development, fast curing, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

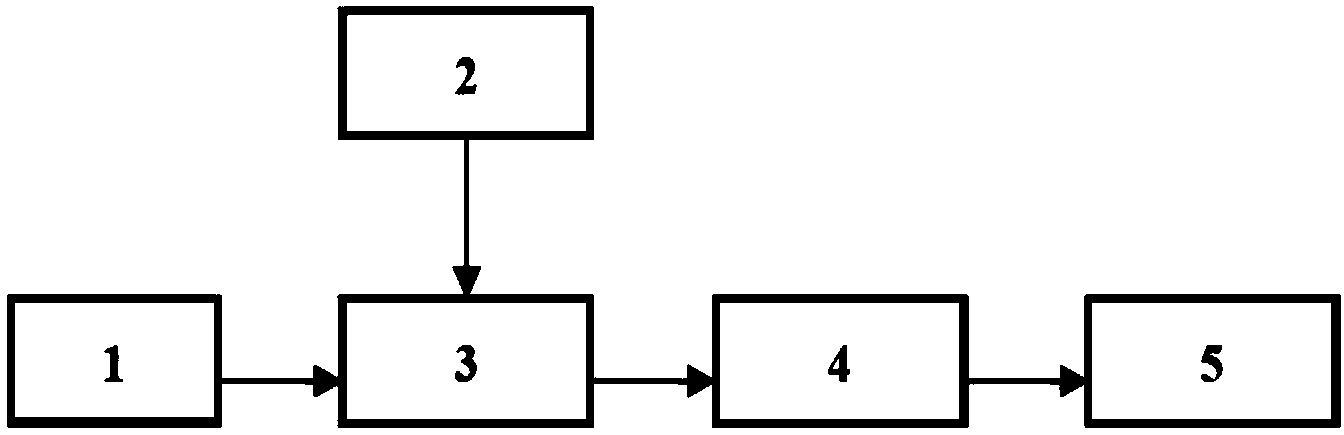

Image

Examples

Embodiment 1

[0022] Put 500kg of large-grained urea with a diameter of 2-5mm into the drum and heat it to 60-90°C; then heat 3.40kg of urea to become molten liquid urea, and mix it with 0.85kg of modifier polyetheramine 400 and 4. 25 kg of curing agent p-phenylene diisocyanate is mixed evenly and sprayed on the surface of urea granules quickly. After 6-9 minutes, it can be directly cured and reacted to form a film on the surface of the fertilizer. This process is repeated 3 times. After the fertilizer is cooled, it can be packaged and stored. The obtained controlled-release fertilizer film material accounts for about 5% of the total weight of all controlled-release fertilizers, and the nutrient release period of this fertilizer in water at 25°C is about 90 days. The results of the determination of the cumulative release rate of N in water for this product are listed in Table 1.

[0023] Table 1

[0024] Release days

Embodiment 2

[0026] Put 500kg of large granular urea with a diameter of 2-5mm into the drum and heat it to 60-90°C; then heat 3.41kg of urea into molten liquid urea and mix it with 1.73kg of modifier p-phenylenediamine and 3.45 The kg curing agent toluene diisocyanate is mixed evenly and sprayed quickly on the surface of the preheated urea granules. After 6-9 minutes, it can be directly cured and reacted to form a film on the surface of the fertilizer. This process is repeated 4 times. After the fertilizer is cooled, it can be packaged and stored. The obtained controlled-release fertilizer film material accounts for about 7% of the total weight of all controlled-release fertilizers, and the nutrient release period of this fertilizer in water at 25°C is about 120 days. The N accumulation release rate determination result of this product in water is listed in Table 2.

[0027] Table 2

[0028] Release days

Embodiment 3

[0030] Put 500kg of large-grained urea with a diameter of 2-5mm into the drum and heat it to 60-90°C; then heat 3.51kg of urea into a molten liquid and mix it with 1.64kg of modifier polymethylene polyaniline Mix it with 3.35kg of curing agent diphenylmethane diisocyanate and spray it quickly on the surface of the preheated urea granules. After 6-9 minutes, it can be directly cured and reacted to form a film on the surface of the fertilizer. This process is repeated 6 times. After the fertilizer is cooled, it can be packaged and stored. The obtained controlled-release fertilizer film material accounts for about 9% of the total weight of all controlled-release fertilizers, and the nutrient release period of this fertilizer in water at 25°C is about 180 days. The N accumulation release rate measurement results of this product in water are listed in Table 3

[0031] table 3

[0032] Release days

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com