Nano transparent insulating paint and its preparing process

A heat-insulating coating and nano-insulation technology, applied in the direction of fire-proof coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor dispersion and poor stability of nano-materials, the method is simple and easy, and the film-forming temperature can be reduced , Improve the effect of heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The present invention also provides a preparation method of nano-transparent heat-insulating coating, comprising the steps of:

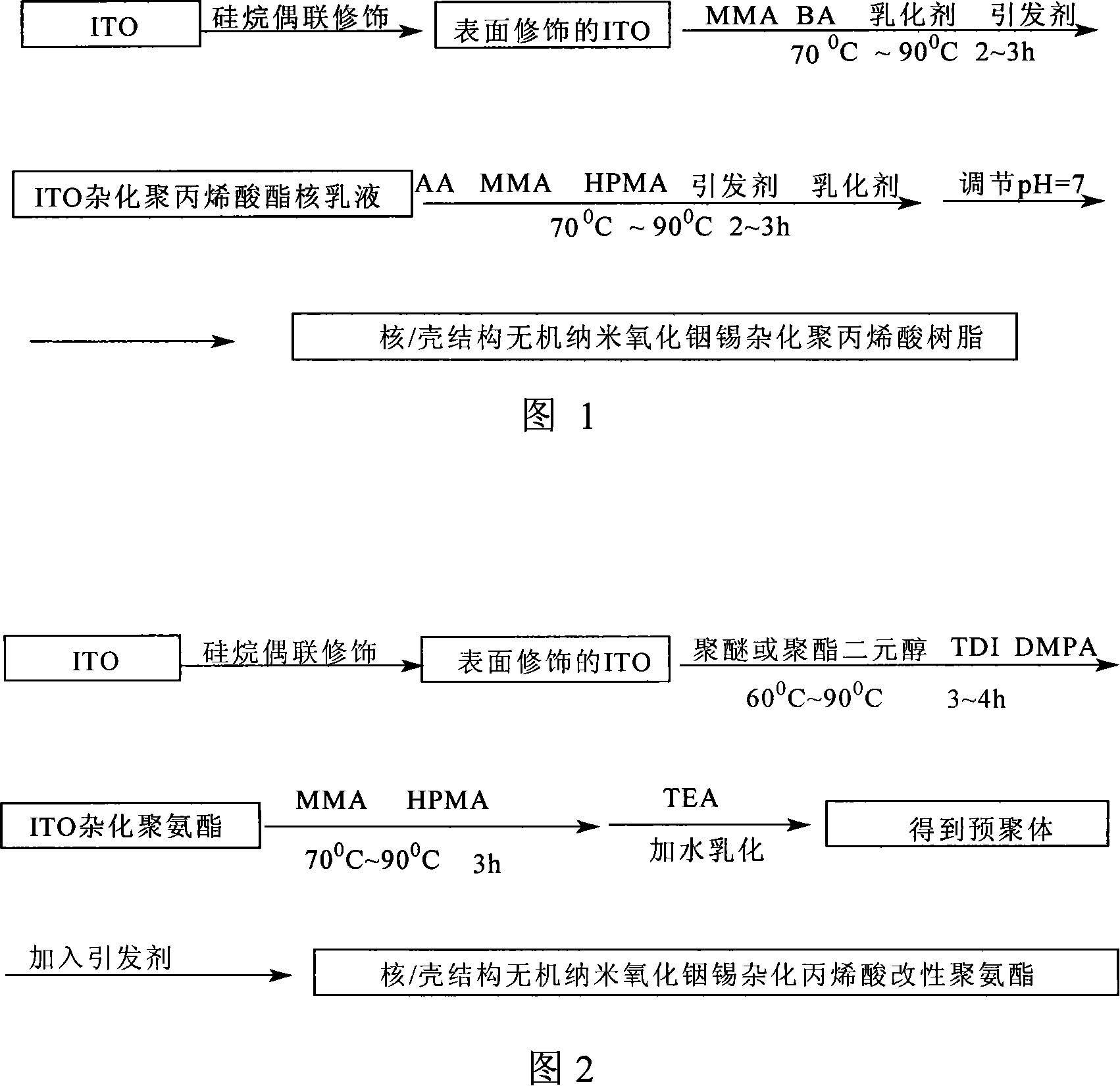

[0051] (1) Synthesis of inorganic nanoparticle hybrid polymer resin with core / shell structure, adopting in-situ polymerization method, allowing inorganic nano heat insulation powder to participate in polymerization reaction to obtain inorganic nanoparticle hybrid polymer resin with core / shell structure, Inorganic nanoparticles are coated in polymer resin by means of chemical bonds;

[0052] (2) Blending the prepared inorganic nanoparticle hybrid polymer resin with coating additives and diluents to prepare nano transparent heat-insulating coatings, the components and weight percentages are as follows:

[0053] Inorganic nanoparticle hybrid polymer resin: 60% to 75%;

[0054] Coating additives: 1% to 10%;

[0055] Thinner: 20% to 35%;

[0056] Preferably, in step (1), during in-situ polymerization, the surface of the inorganic nano heat-insul...

example 1

[0059] In this example, the inorganic nano-particle hybrid polymer resin is an inorganic nano-indium tin oxide (ITO) hybrid polyacrylic resin, and the components and weight percentages of the nano-transparent heat-insulating coating are as follows:

[0060] Inorganic nano-indium tin oxide (ITO) hybrid polyacrylic resin: 60% to 75%;

[0061] Coating additives: 1% to 10%;

[0062] Thinner: 20% to 35%.

[0063] In the hybrid resin, the content of nano heat insulating powder indium tin oxide (ITO) is 1% to 10%, and its particle size is 10 to 100nm. The inorganic nanomaterials are processed by silane coupling agent or titanate Surface Modification.

[0064] The coating additives include at least one of: a leveling agent, a defoamer, a film-forming aid, and a thickener. The thickener is a hydroxyacrylic acid water-soluble dispersion (WT-102), and the film-forming aid The agent is alcohol ester compound (alcohol ester-12), the leveling agent is acrylic acid copolymer, and the defo...

example 2

[0073] In this example, the inorganic nano-particle hybrid polymer resin adopts inorganic nano-indium tin oxide (ITO) hybrid acrylic acid-modified polyurethane, and the components and weight percentages of the nano-transparent heat-insulating coating are as follows:

[0074] Inorganic nano-indium tin oxide (ITO) hybrid acrylic modified polyurethane: 60% to 75%;

[0075] Coating additives: 1% to 10%;

[0076] Thinner: 20% to 35%.

[0077] Among them, inorganic nano-indium tin oxide (ITO) hybrid acrylic acid modified polyurethane is used as a film-forming substance of nano-transparent heat-insulating coating, and its components and parts by weight are as follows:

[0078] Polyether or polyester diol 30~60;

[0079] Aromatic diisocyanate (TDI) 10-30;

[0080] Chain extender short chain aliphatic diol 1~5;

[0081] Crosslinking agent trihydric polyol (DMPA) 1~6;

[0082] Short-chain aliphatic neutralizer triethylamine (TEA) 1.5-4.5;

[0083] End-capping agent hydroxy acrylat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com