Detachable vibration reduction gear

A technology of gears and damping grooves, applied in belts/chains/gears, components with teeth, portable lifting devices, etc. The effect of generalization, high practical value and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

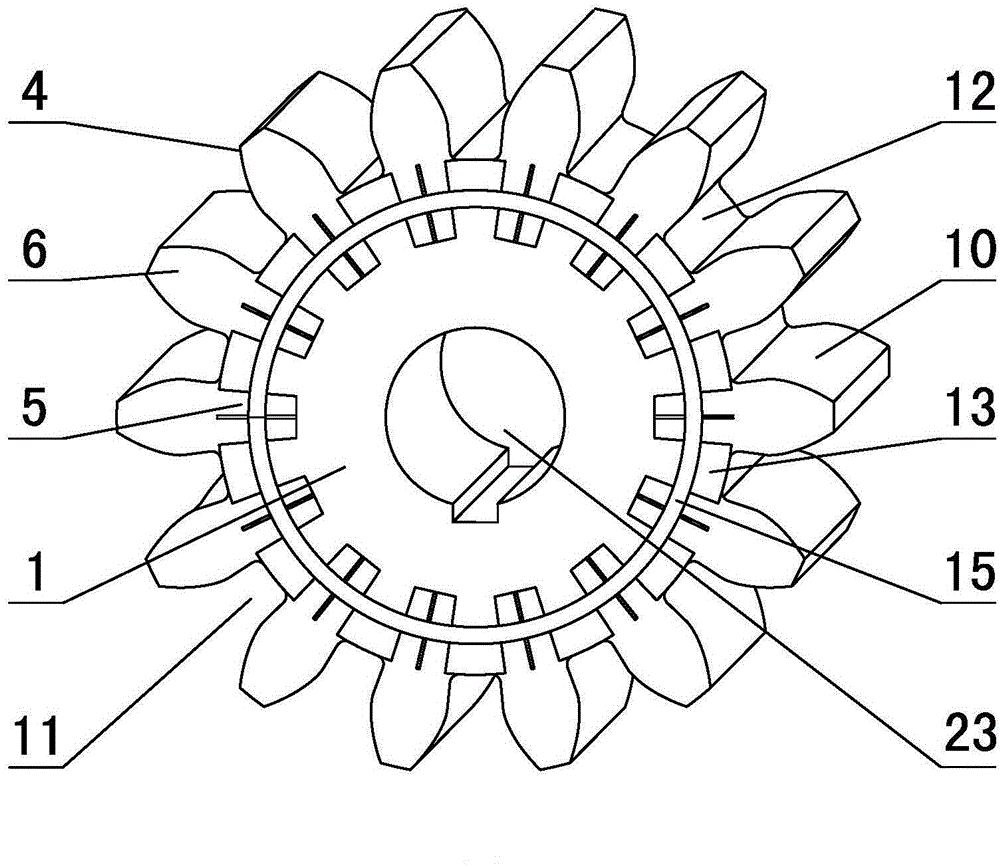

[0025] in such as figure 1 In the shown embodiment 1, a detachable damping gear is provided with 14 gear teeth, and the center of the gear is provided with a shaft hole 23, and the detachable damping gear includes a base wheel 1 (see image 3 ), the diameter of the base wheel is equal to the diameter of the root circle of the gear with the basic modulus of 6 (that is, the diameter of the root circle of the gear with the number of teeth 14 and the modulus of 6), and the upper edge of the base wheel is evenly There are axial through grooves 3 with the same number as the number of gear teeth. The opening width of the through grooves is greater than the width of the bottom of the through grooves. The angle between the side walls on both sides of the through grooves is 6 degrees. Embedded with a detachable gear tooth 4 whose tooth width is consistent with the length of the through groove, the detachable gear tooth and the base wheel form a complete gear, and the detachable gear too...

Embodiment 2

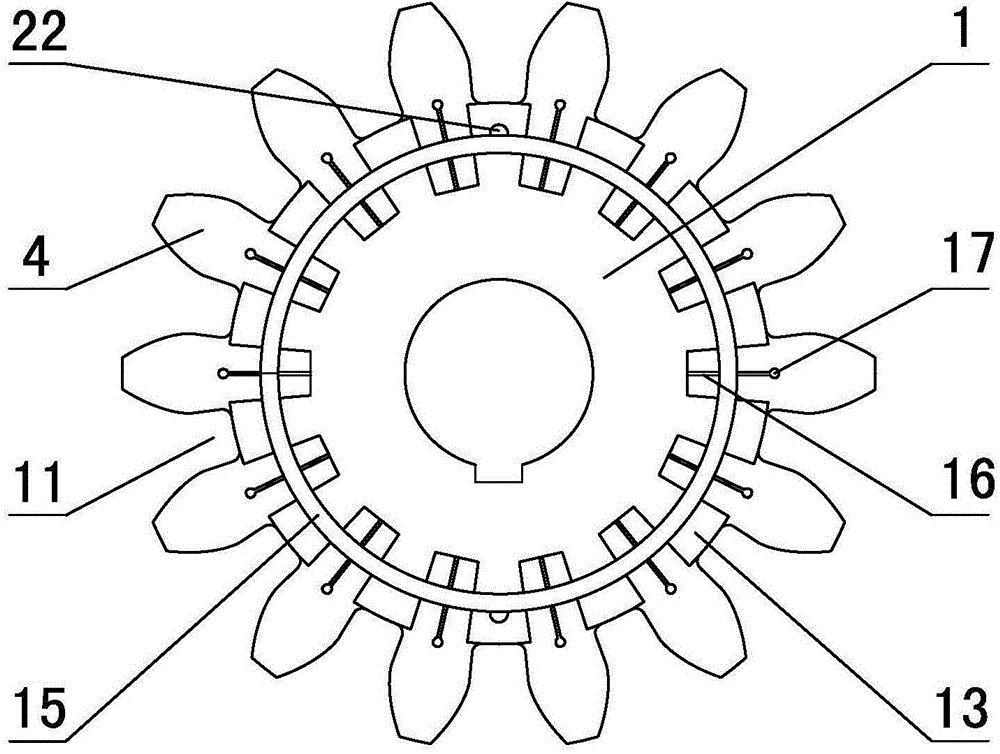

[0027] exist figure 2 In the shown embodiment 2, the angle between the side walls on both sides of the through groove is 3 degrees, the cross section of the vibration damping groove is rectangular, and the bottom of the vibration damping groove expands to form a cylindrical buffer chamber 17 in cross section. , the width of the damping groove is 10% of the bottom width of the through groove, and the diameter of the cylindrical buffer cavity is 1.5 times the width of the damping groove. Embodiment 2 The cross-section of the fan-shaped ring-shaped fixing groove on the two end faces of the stopper is a circular segment shape greater than a semicircle (see Figure 6 ), the notch width of the fan ring fixing groove is slightly smaller than the maximum width of the fixing groove (that is, the notch width is slightly smaller than the diameter of the fixing bar), and the cross section of the circular fixing bar is adapted to the cross section of the fixing groove , the ring-shaped f...

Embodiment 3

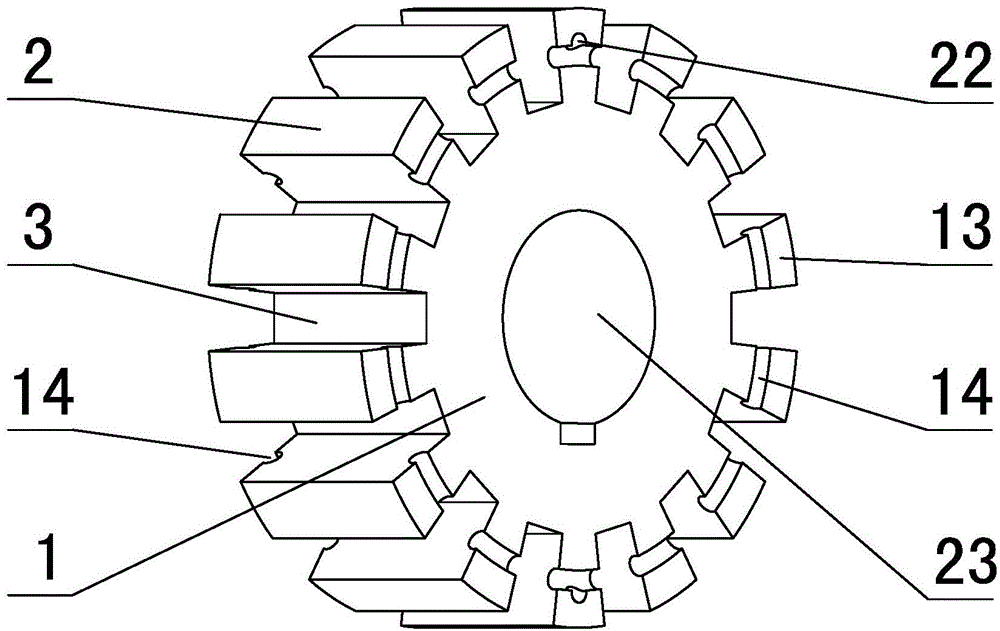

[0029] exist Figure 9 In the shown embodiment 3, the number of teeth of the gear is 14, and the gear module is 8, which is larger than the basic module of embodiment 1. The tooth head bump on the gear teeth is formed with a flat surface at the end of the extension direction. The side walls of the structure face 18 (see Figure 7 ), the upper surface of the tooth head bump is smoothly connected with the tooth profile curved surface of the detachable gear tooth, forming half of the groove bottom surface of the detachable vibration-damping gear tooth groove, and the side wall surface is on the axial center surface of the detachable vibration-damping gear The opposite side walls of two adjacent detachable gear teeth are in close contact with each other, and the upper surfaces of the protrusions of the tooth heads are smoothly connected to form a complete groove bottom surface of the tooth groove of the detachable damping gear. The included angle between the side walls on both si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com