Composite conformable pressure vessel

a pressure vessel and conformation technology, applied in the field of pressure vessels, can solve the problems of reducing the driving range of the vehicle, limiting consumer acceptance of such conversions, and reducing the volume of stored cng, so as to reduce the tendency of adjacent cells to peel apart and strengthen the pressure vessel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

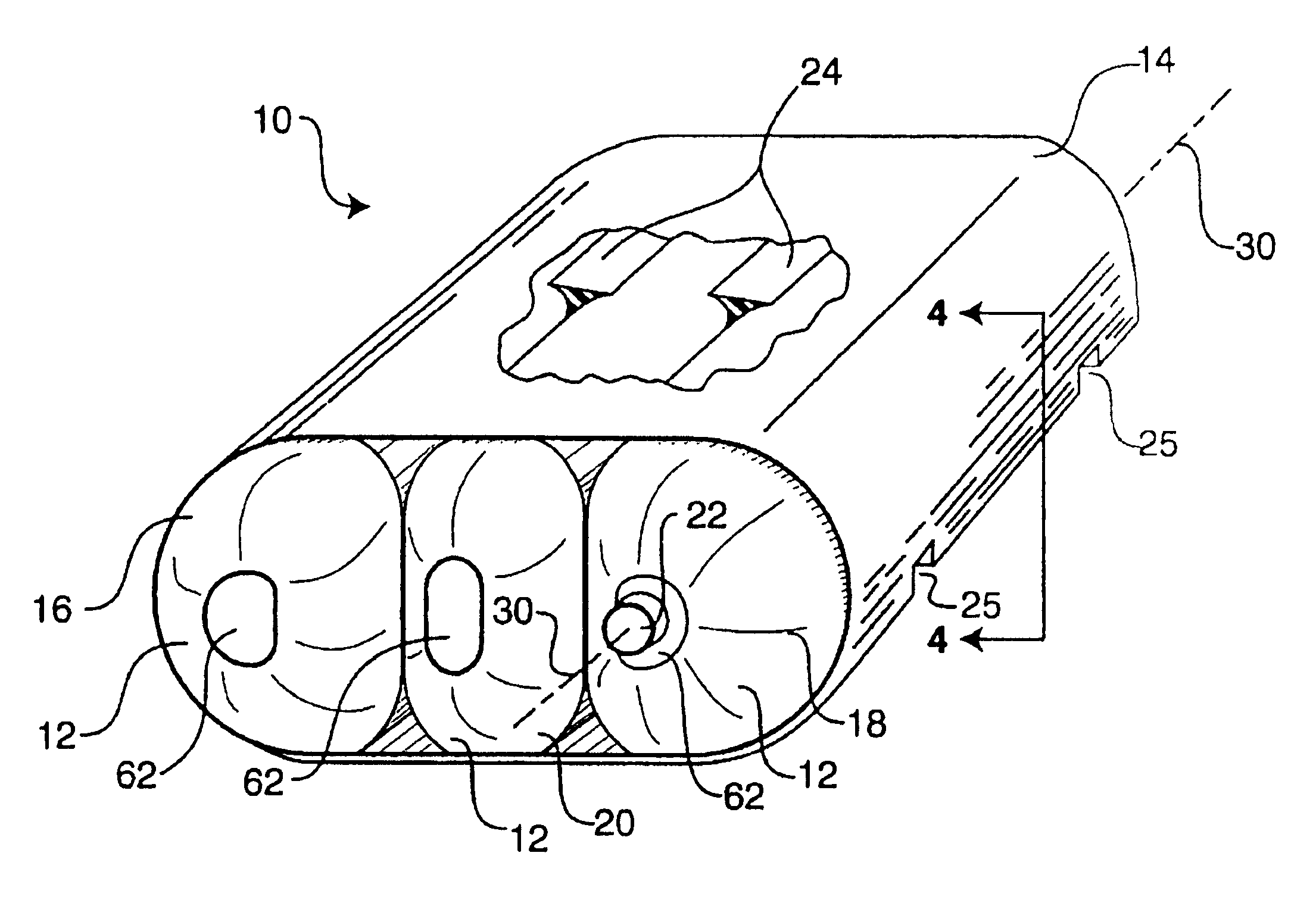

[0041]Reference is now made to the figures wherein like parts are referred to by like numerals. The present invention relates to a pressure vessel generally, and more specifically to a tank for holding compressed natural gas (“CNG”) for fueling a vehicle (not shown). One embodiment of the present pressure vessel is indicated generally at 10 in FIG. 3. This embodiment of the pressure vessel 10 includes three cells 12 secured within a web 14. The three cells 12 include a left end cell 16, a right end cell 18, and one interior cell 20. The cells 12 have a novel geometry and other important characteristics which will be described in detail after the other main components of the pressure vessel 10 are noted.

[0042]The right end cell 18 is preferably configured with a valve 22 to control fluid flow in and out of the pressure vessel 10. The valve 22 preferably includes pressure relief means for the controlled release of pressurized fluid from the pressure vessel 10 if the internal pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| outer wall radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com