Magnetoresistance brushless multi-polar rotation transformer

A resolver and reluctance technology, which is applied in the direction of transformers, inductors, electrical components, etc., can solve the problems of complex structure of resolver and inapplicability of multi-pole angle measurement with a small number of pole pairs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

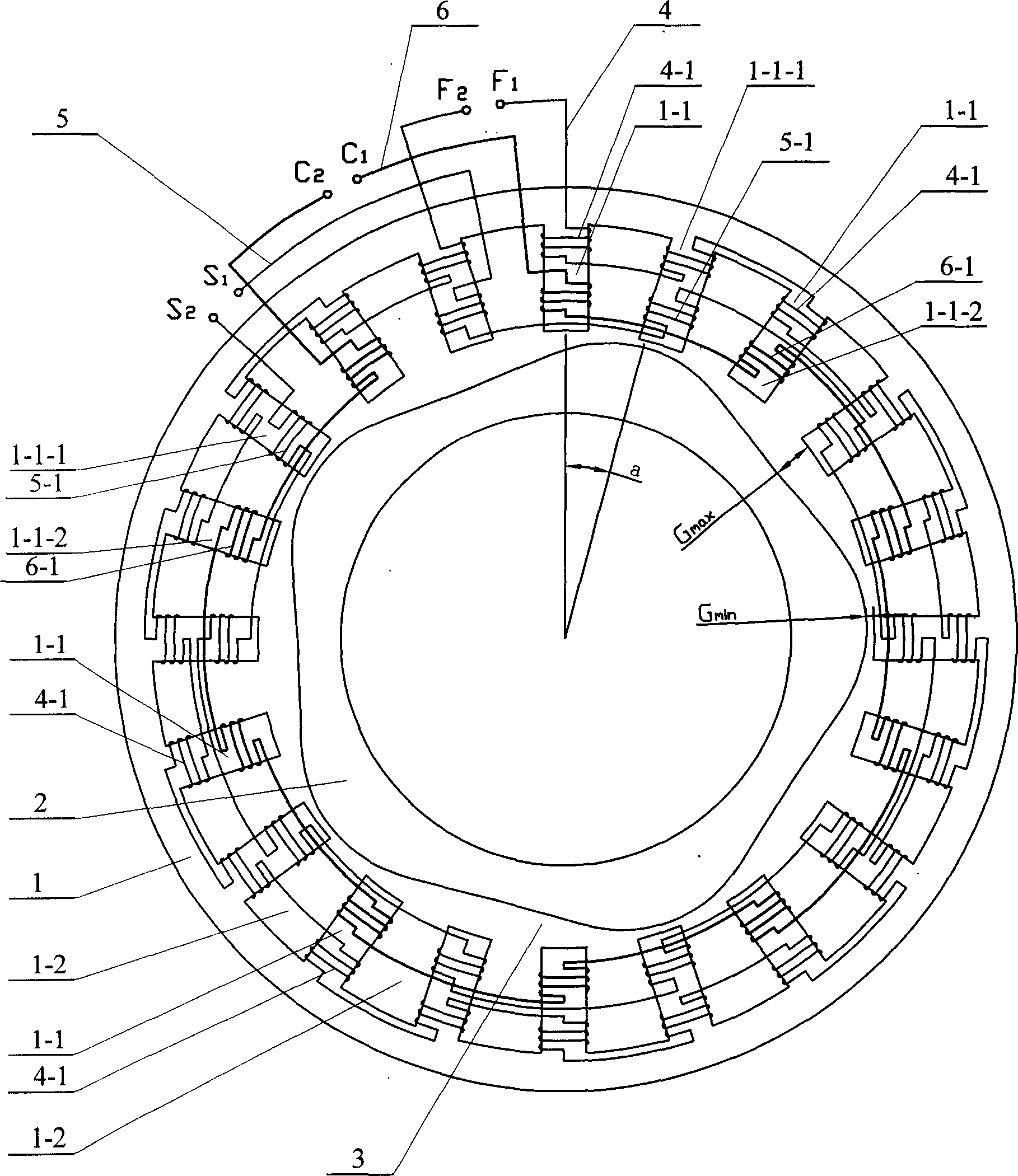

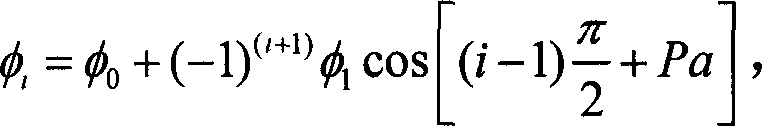

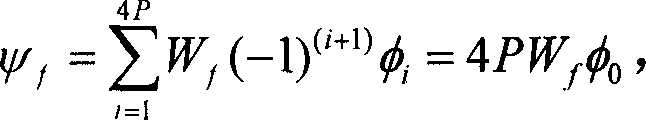

[0014] Specific implementation manner one: such as figure 1 As shown, the resolver of this embodiment is composed of a rotor 2, a stator 1, a first coil 4-1, a second coil 5-1, and a third coil 6-1. The outer surface of the rotor 2 and the stator 1 An air gap 3 is provided between the inner circular surfaces of the rotor 2; the outer circular surface of the rotor 2 is uniformly provided with P crests and P troughs, and the crests and troughs are smoothly connected to each other to form the wavy outer circular surface of the rotor 2, wherein , P is the number of pole pairs of the resolver; the inner circular surface of the stator 1 is provided with a plurality of through slots 1-2 along the axial direction, and there are convex teeth 1- between the two adjacent through slots 1-2. 1. The inner circular surface of the stator 1 is uniformly arranged with 4P convex teeth 1-1 along the circumferential direction, and the 4P convex teeth 1-1 are sequentially divided into 2P odd convex tee...

specific Embodiment approach 2

[0015] Specific implementation manner two: such as figure 1 As shown, the difference between this specific embodiment and the first embodiment is that the stator 1 and the rotor 2 are formed by superimposing a plurality of punched pieces of electrical steel. Other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

[0016] Specific implementation manner three: such as figure 1 As shown, the difference between this specific embodiment and the first embodiment is that the number of turns of the second coil 5-1 and the third coil 6-1 is the same. Other components and connection relationships are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com