Pipeline inner wall cleaning device

A technology for cleaning inner walls and pipes, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as pipe blockage, achieve the effects of preventing inconsistencies, preventing water pipe entanglement, and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

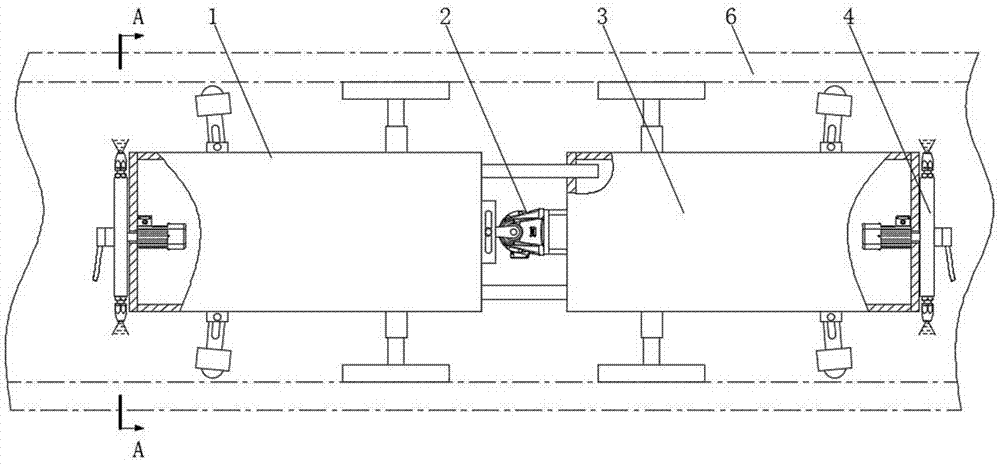

[0025] combined with Figure 1-4 As shown, a pipeline inner wall cleaning device includes a front traveling mechanism 1, a telescopic mechanism 2, and a rear traveling mechanism 3 connected sequentially from front to back; A cleaning mechanism 4 is provided at the diverging ends of the front traveling mechanism 1 and the rear traveling mechanism 3; In this embodiment, the front traveling mechanism 1 and the rear traveling mechanism 3 both include a cylinder body, a fixed arm assembly, and a walking roller assembly; and the retractable fixed arm that loosens the inner wall of the pipeline; the walking roller assembly includes a plurality of walking arms that are connected to the cylinder and are evenly distributed radially along the outer circular surface of the cylinder, and the end of the walking arm that contacts the inner wall of the pipeline is rotatably connected with a roller , the telescopic mechanism 2 adopts a linear oil cylinder, that is, the cylinder body of the oi...

Embodiment 2

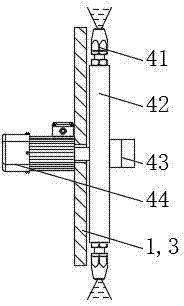

[0029] For implementing the present invention better, realize cleaning pipeline inner wall without dead angle, on the basis of embodiment 1, in conjunction with attached Figure 1-4 Further, the cleaning mechanism 4 includes a first motor 44 fixedly connected to the front end of the front traveling mechanism 1 or the rear end of the rear traveling mechanism 3, a disc 42 fixedly connected to the output shaft of the first motor 44, and a disc 42 detachably connected to the disc 42 the high-pressure nozzle 41 on the outer surface; the disc 42 is provided with a water channel with one end communicating with the high-pressure nozzle 41 and the other end communicating with the external water source.

Embodiment 3

[0031] In order to better implement the present invention, prevent the water pipe from being entangled due to the rotation of the motor, on the basis of Embodiment 2, in combination with the attached Figure 1-4 Further, the end surface of the disc 42 away from the first motor 44 is detachably connected with a rotary joint 43, one end of the rotary joint 43 communicates with the water channel in the disc 42, and the other end of the rotary joint 43 communicates with an external water source. In this embodiment, the model of the rotary joint 43 is GP-621.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com