Vortex compressor

A scroll compressor and scroll technology, applied in the field of scroll compressors, can solve the problems of increased power loss, reduced discharge resistance, narrowing of the central chamber T3, etc., to achieve increased communication area, reduced power loss, The effect of increased compression ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

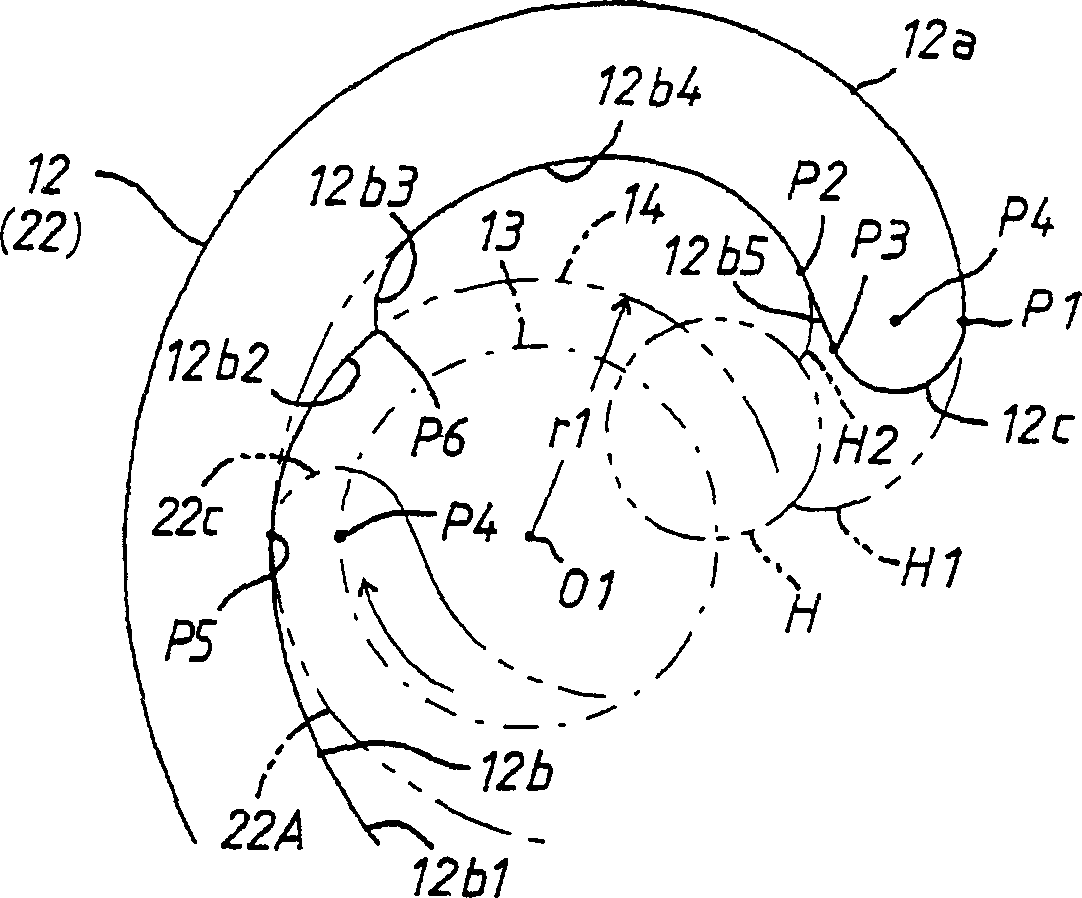

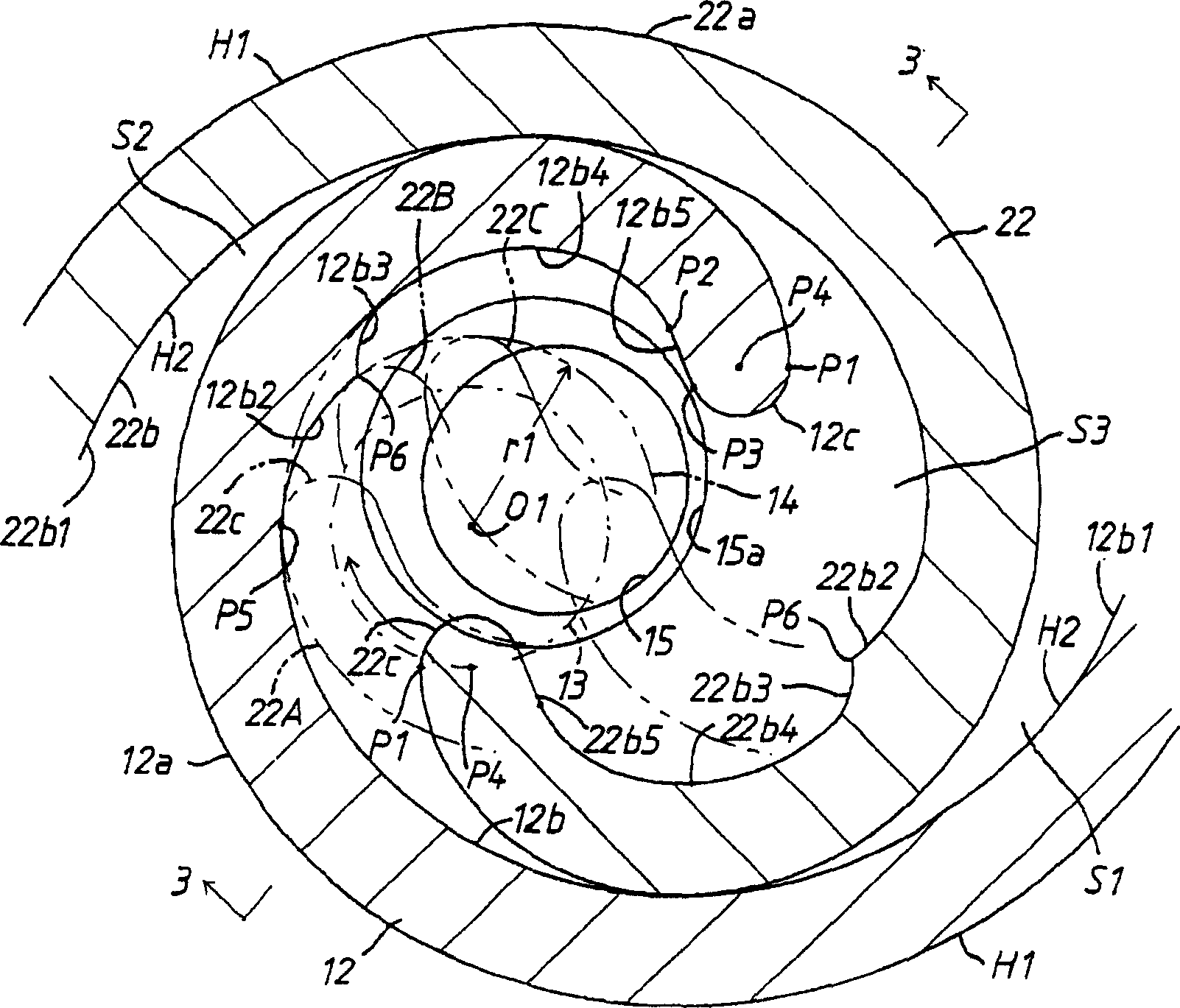

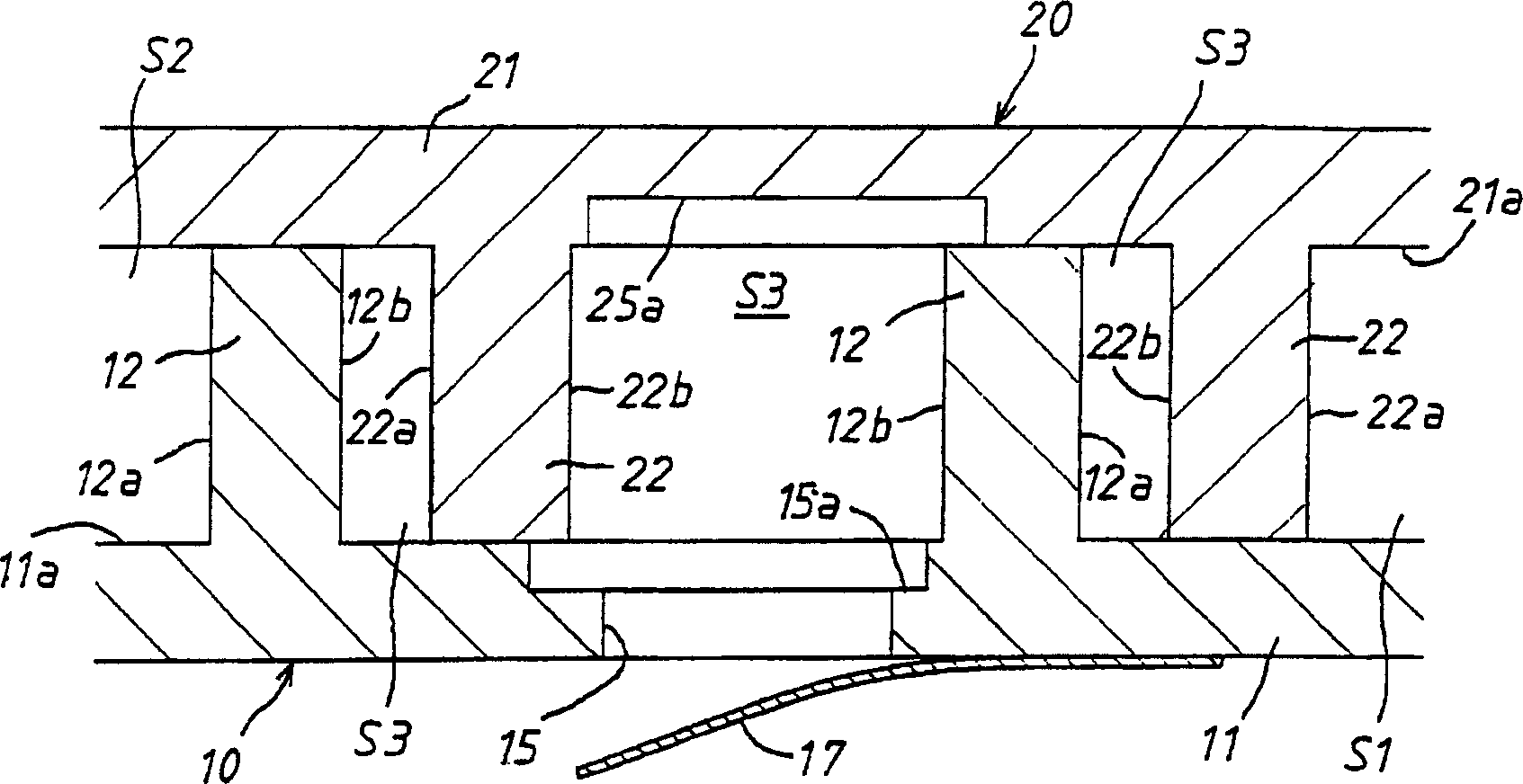

[0043] First, according to Figure 1 ~ Figure 3 , the first embodiment of the scroll compressor according to the present invention will be described. mainly as figure 2 and image 3 As shown, in the scroll compressor of this embodiment, the fixed scroll 10 formed by the fixed-side end plate 11 and the scroll-shaped fixed-side overlapping portion 12 erected on its inner surface 11 a , and the movable-side end plate 21 and a movable scroll 20 formed by a scroll-shaped movable side lap 22 erected on its inner surface 21a. The movable scroll 20 is assembled so that the outer peripheral portion of the inner surface 21a of the movable side end plate 21 and the upper end surface of a side peripheral wall (not shown) erected on the entire outer periphery of the fixed side end plate 11 are airtight and slidable. It abuts against the ground and rotates relative to the fixed scroll 10 without rotating. The two scrolls 10, 20 are combined such that the inner peripheral surface 12b of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com