Hot pepper shank removing machine

A pepper and rack technology, applied in application, food processing, food science and other directions, can solve the problems of high labor intensity, waste of resources, and high cost, and achieve the effect of increasing the cutting handle, reducing labor intensity and simple product structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

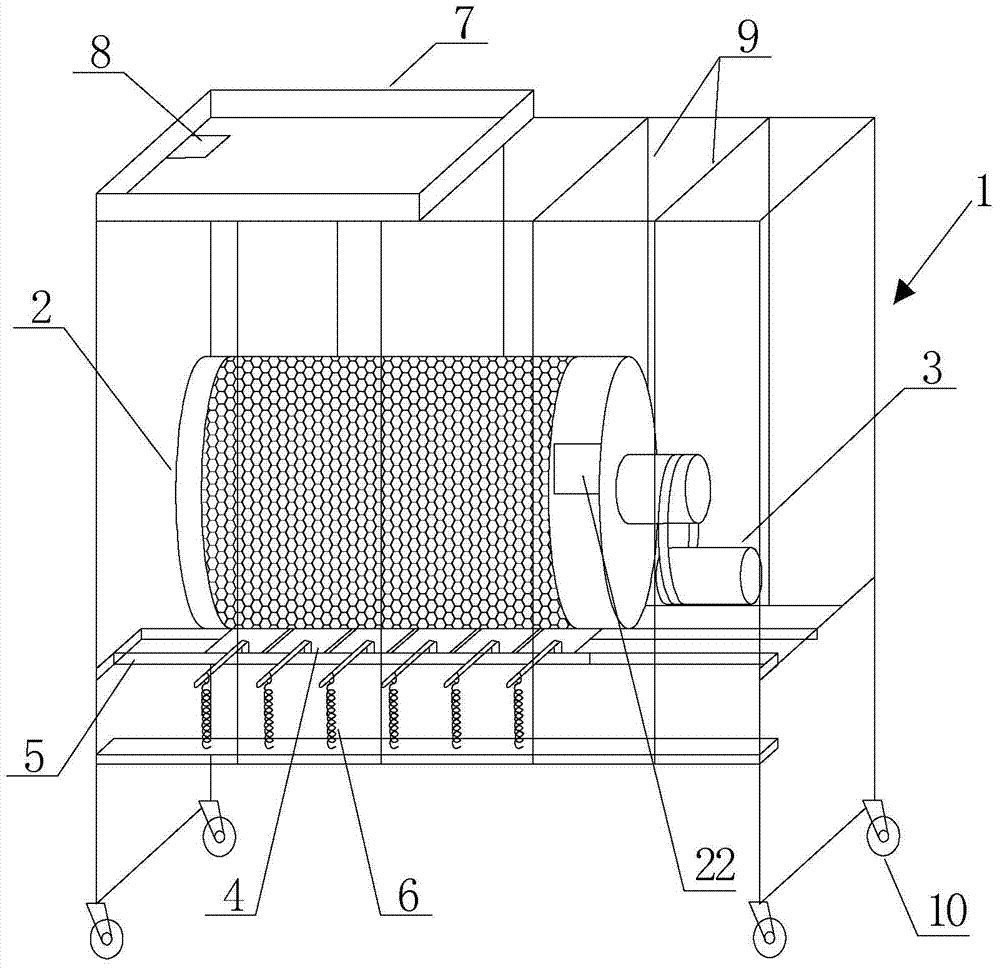

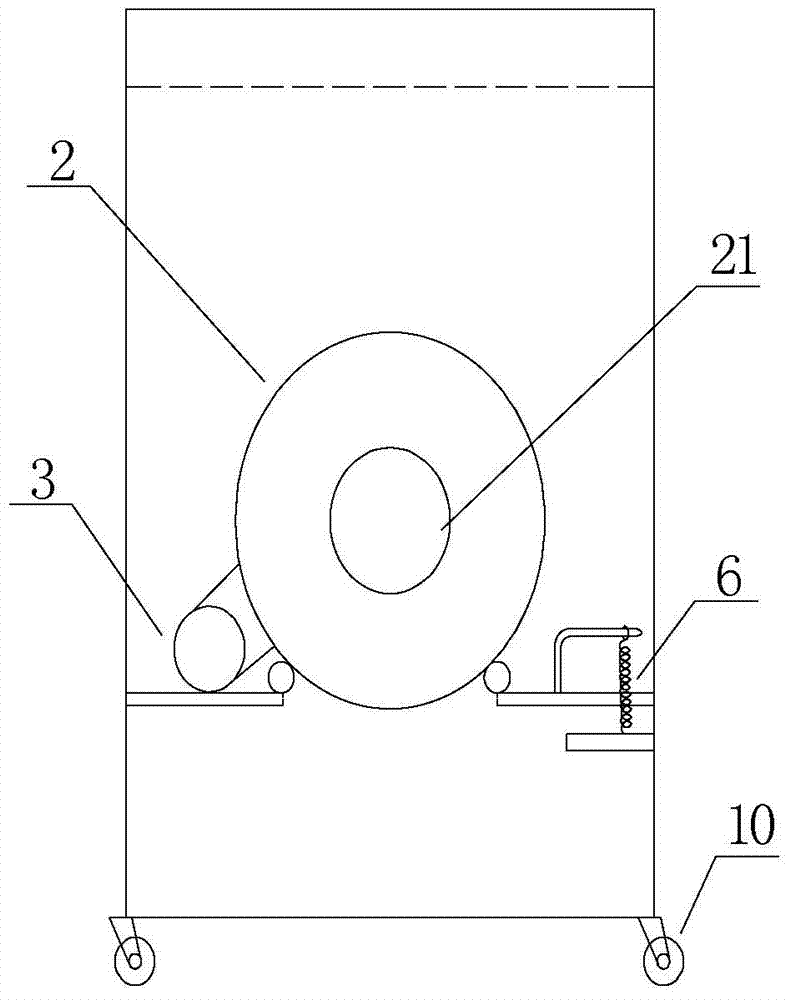

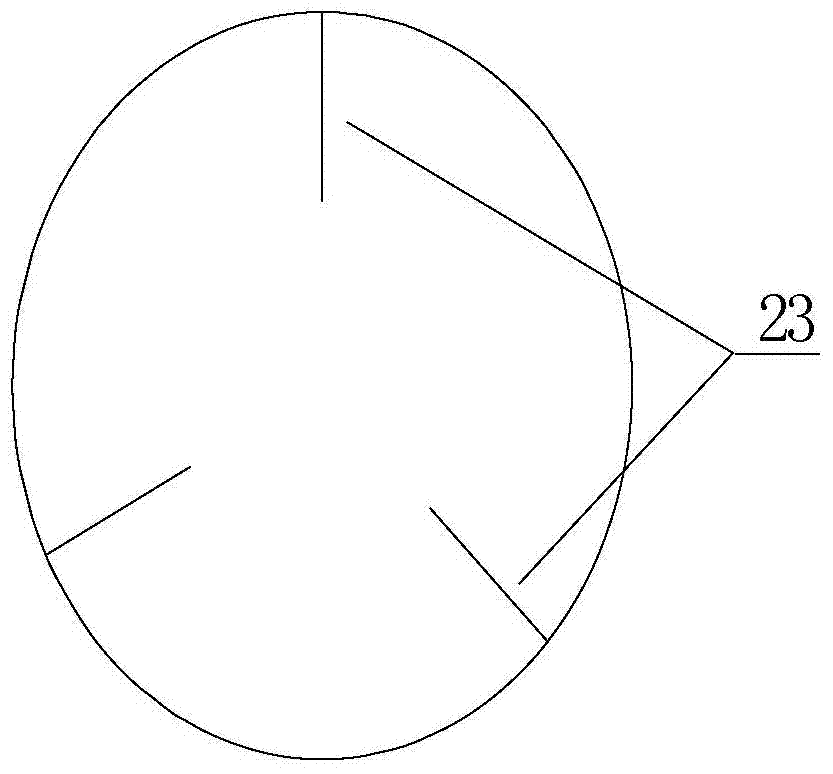

[0017] The present invention will be described in detail below in conjunction with accompanying drawing, as shown in the figure: the capsicum handle picking machine of the present embodiment comprises frame 1, and described frame is provided with the motor 3 that drum 2 and drive drum rotate, and described drum It is a mesh drum, and the round surface of one end of the drum is provided with a feed port 21, and the side of the other end is provided with a discharge port 22, and the outer side of the bottom end of the drum is provided with a row of blades 4 for picking handles along its tangential direction. One end of the knife edge is close to the drum, and the other end is placed on the cross bar 5 of the frame and connected with the frame by a tension spring 6. After the pepper enters from the feeding port of the drum, the motor drives the drum to rotate and the pepper stalk protrudes from the mesh of the drum, and the pepper stalk is cut off by a row of blades arranged outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com