Special clamp for thin and long cylindrical thin wall assembly

A special fixture and combination technology, applied in the direction of clamping, manufacturing tools, supports, etc., can solve the problems of long positioning time, low positioning accuracy, and the inability to achieve special fixtures, saving the time of manual measurement and positioning, preventing damage, Guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

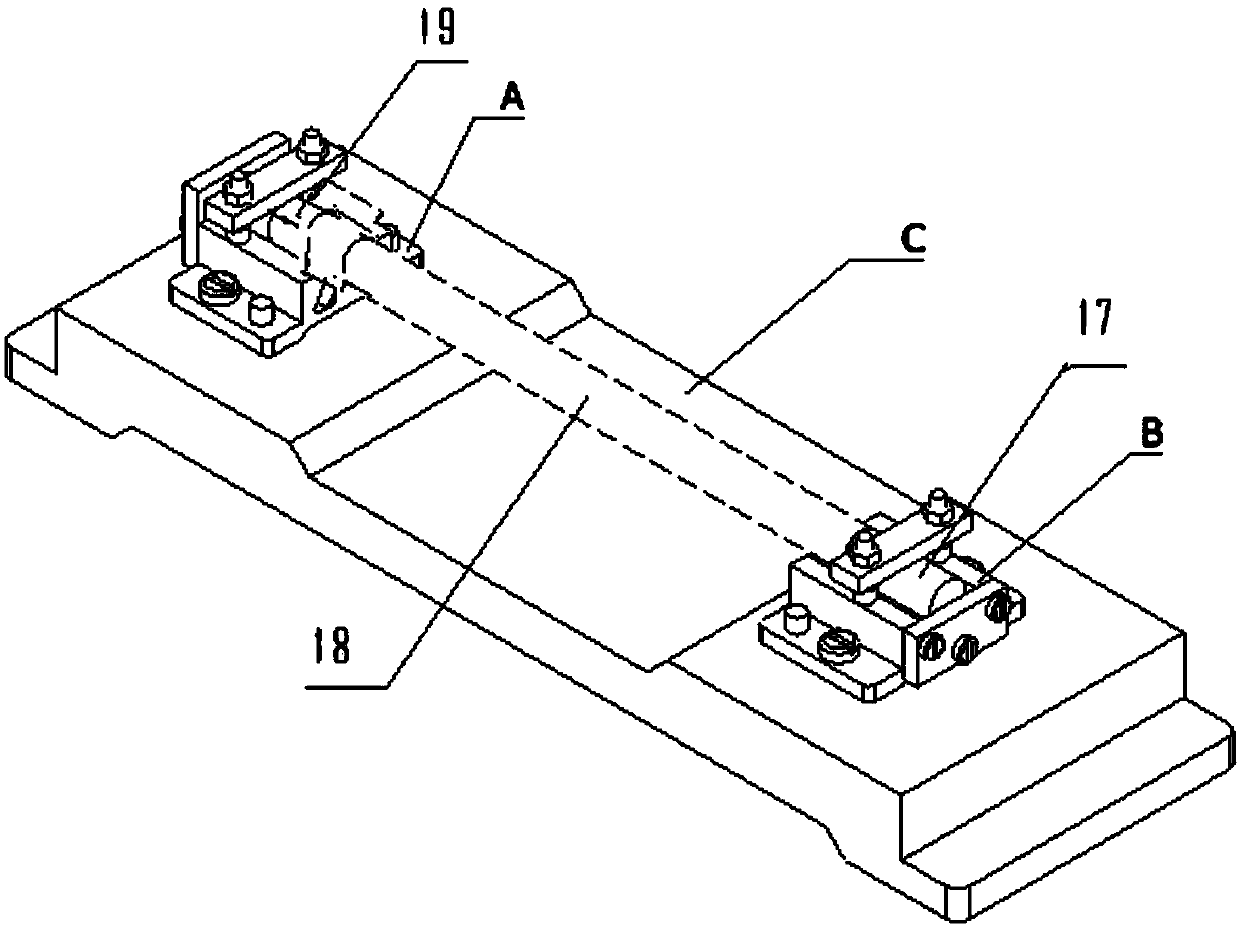

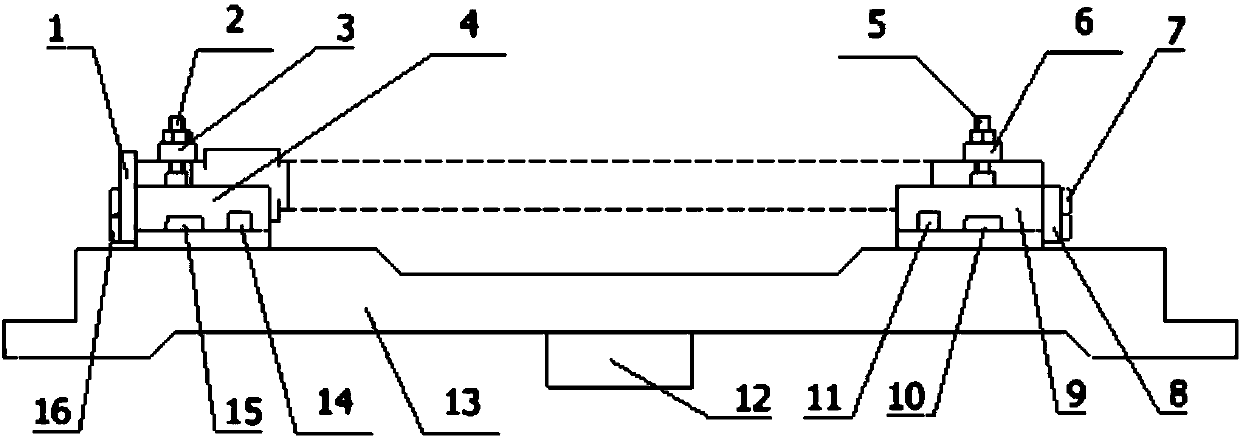

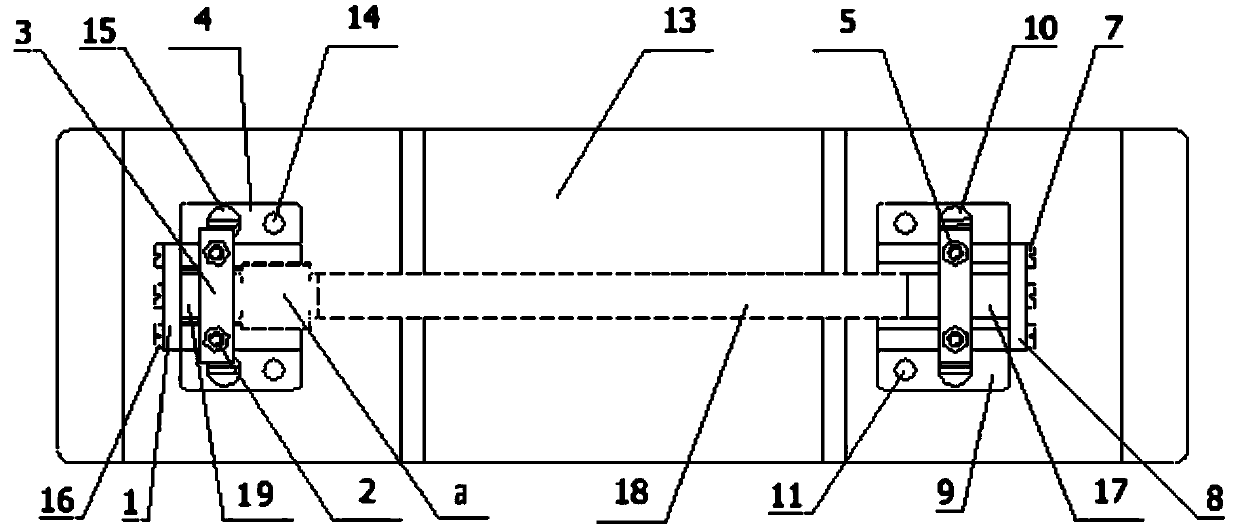

[0012] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

[0013] Such as figure 1 , 2 , Shown in 3, a kind of special fixture of slender cylindrical thin-walled assembly, comprises front clamping body B, rear clamping body A and clamping base C, and special clamping body is positioned and clamped to assembly by front and rear clamping body. The shape of the rear V-shaped block 4 in the rear clamp body A is different from that of ordinary V-shaped blocks. It is specially processed, that is, a tail groove is processed on one side of the rear V-shaped block 4. The shape of the tail fin a of the wall assembly is profiled, so that the lower surface of the tail fin a of the slender cylindrical thin-walled assembly can be inserted into the groove and fit closely with the upper surface of the groove, and the rear V-shaped block 4 The other side is processed with a square groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com