Process for preparing titanium dioxide with dispersion sensitive property and high weatherability

A titanium dioxide, high-weather-resistant technology, applied in the treatment of dyed low-molecular-weight organic compounds, fibrous fillers, etc., can solve the problems of broken aggregates, difficult to control the density of the coating layer, affecting the weather resistance and dispersibility of products, etc. Effects of weatherability and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

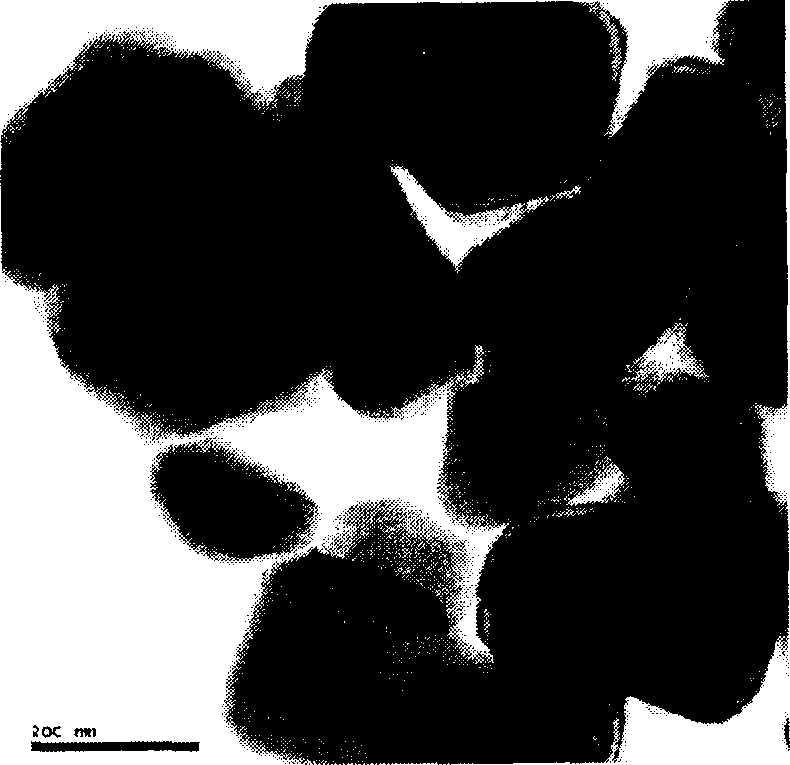

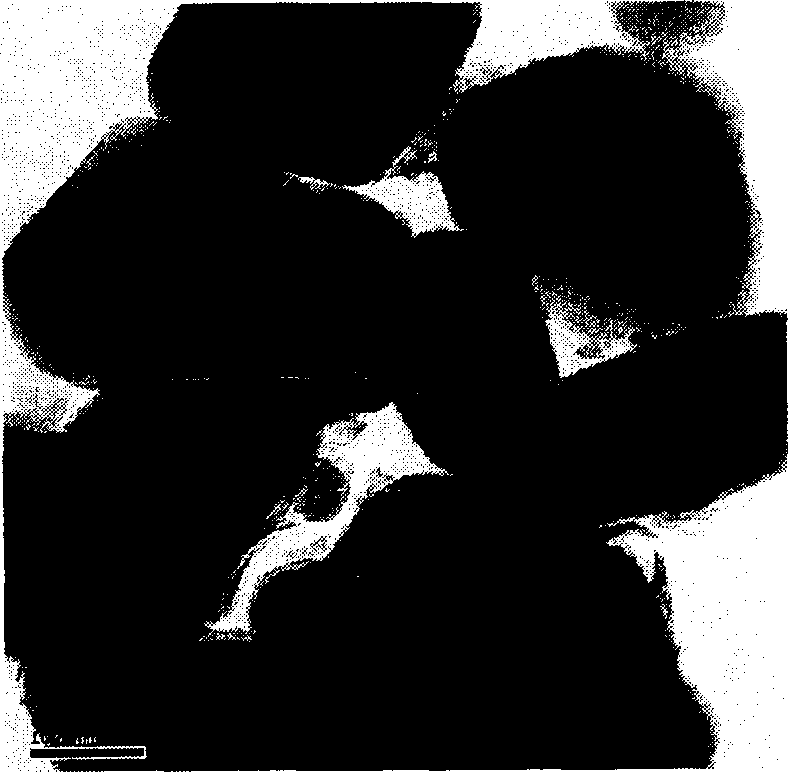

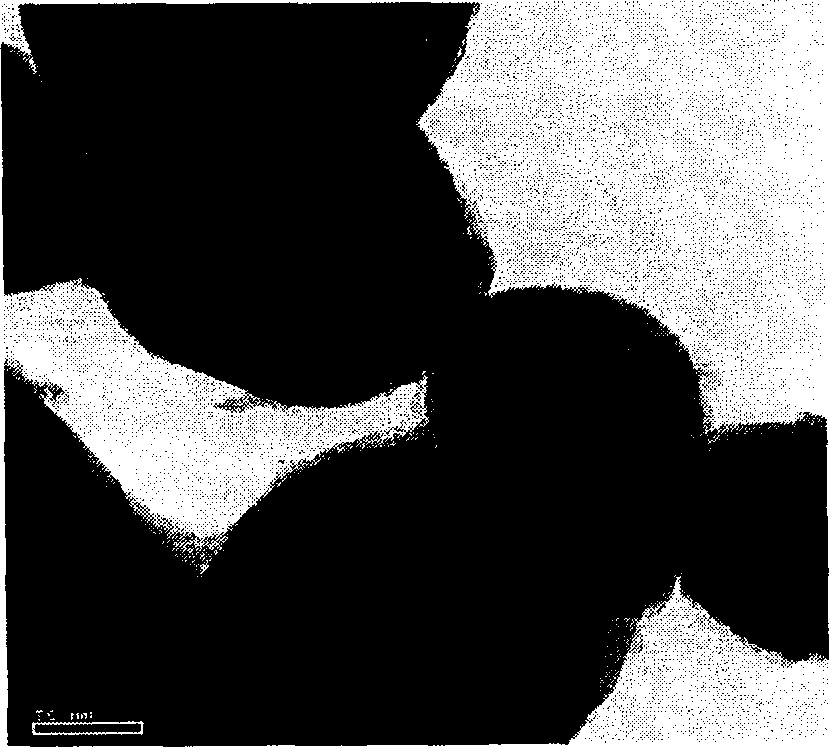

Image

Examples

example 1

[0021] Get 700g of sulfuric acid method rutile type titanium dioxide without surface treatment, add deionized water to make a slurry with a concentration of about 700g / l, add 28ml sodium hexametaphosphate solution (concentration is based on P 2 o 5 Calculated at 50g / l, the amount added is based on TiO 2 0.2%), 0.74ml isopropanolamine (content 98%, density: 0.9650g / ml, the amount added is based on TiO 2 0.1% in total) as a dispersant, and disperse for 60 minutes at a speed of 3000 rpm on a high-speed disperser. Then add deionized water to dilute the dispersed slurry to 300g / l, take 1000ml of it, raise the temperature of the slurry to 91°C, add NaOH solution to adjust the pH value to 10, and add 60ml of sodium silicate solution within 40 minutes (The concentration of sodium silicate is based on SiO 2 Calculated at 50g / l, the amount added is based on TiO 2 1%) and dilute sulfuric acid (concentration is 10%, w / w), matured for 20 minutes after adding, cooled the slurry to a tem...

example 2

[0023] Get 700g of sulfuric acid method rutile type titanium dioxide without surface treatment, add deionized water to make a slurry with a concentration of about 700g / l, add 14ml sodium hexametaphosphate solution (concentration is based on P 2 o 5 Calculated at 50g / l, the amount added is based on TiO 2 0.1% in total), 1.48ml of isopropanolamine (content 98%, density: 0.9650g / ml, the amount added is based on TiO 2 0.2% in total) as a dispersant, and dispersed for 60 minutes at a speed of 3000 rpm on a high-speed disperser. Then the dispersed slurry is diluted to 200g / l with deionized water, 1000ml of it is taken, the temperature of the slurry is raised to 92°C, the pH value of the slurry is adjusted to 11, and within 50 minutes, 40ml of sodium silicate ( The concentration of sodium silicate is SiO 2 Calculated at 50g / l, the amount added is based on TiO 2 1%) and dilute sulfuric acid (concentration is 10%, w / w), matured for 20 minutes after adding, cooled the slurry to a te...

example 3

[0025] Get 700g of sulfuric acid method rutile type titanium dioxide without surface treatment, add deionized water to make a slurry with a concentration of about 700g / l, add 28ml sodium hexametaphosphate solution (concentration is based on P 2 o 5 Calculated at 50g / l, the amount added is based on TiO 2 0.2%), 0.77ml triethanolamine (content 80%, density: 1.140g / ml, the amount added is based on TiO 2 0.1% in total) as a dispersant, and dispersed for 60 minutes at a speed of 3000 rpm on a high-speed disperser. Then add deionized water to dilute the dispersed slurry to 250g / l, take 1000ml of it, raise the temperature of the slurry to 92°C, add NaOH solution to adjust the pH value to 10, and add 50ml of sodium silicate solution within 40 minutes (The concentration of sodium silicate is based on SiO 2 Calculated at 50g / l, the amount added is based on TiO 21%) and dilute sulfuric acid (concentration is 10%, w / w), matured for 20 minutes after adding, cooled the slurry to a tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com