Method for producing iron ore concentrate through suspension magnetizing roasting with siderite as reducing agent

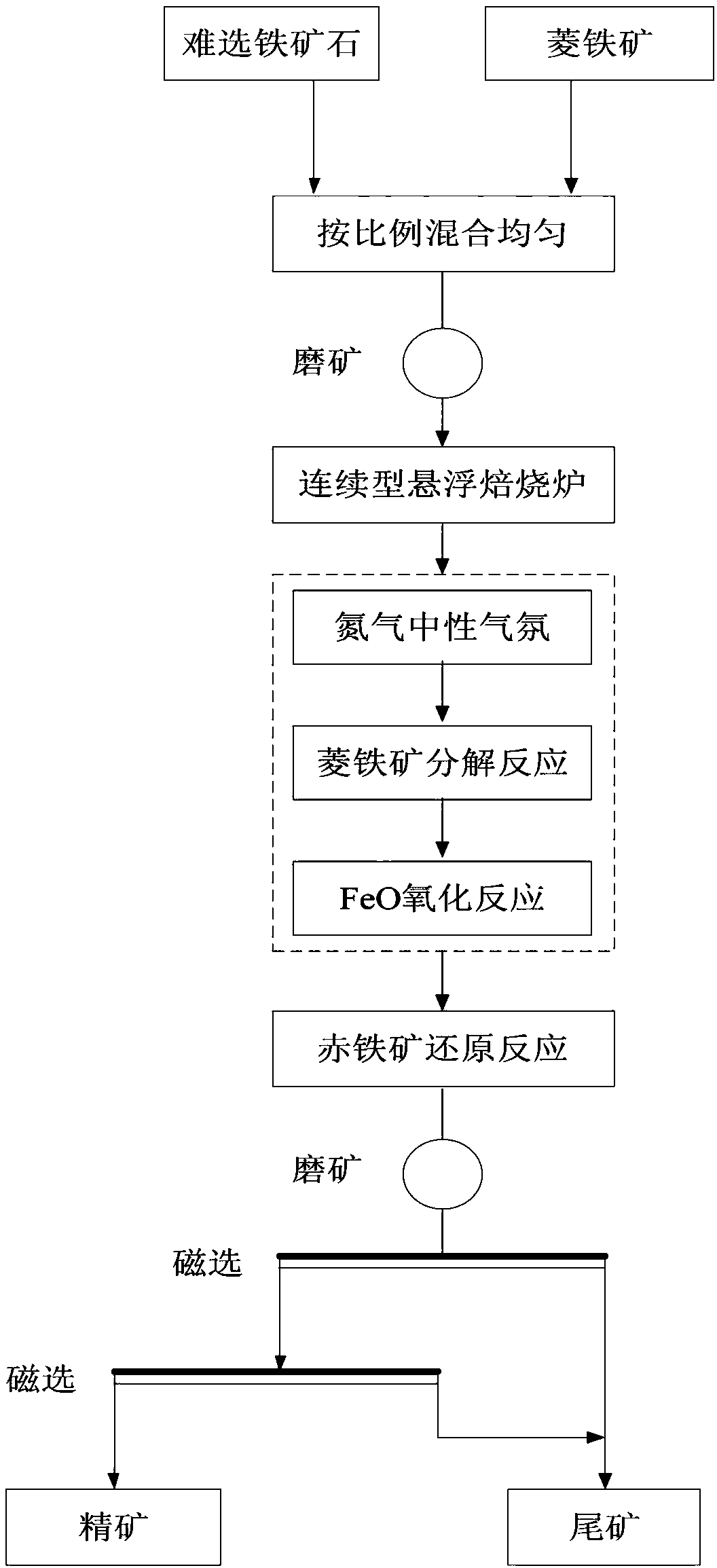

A magnetized roasting and siderite technology, applied in the field of mineral processing, can solve the problems of environmental pollution, increase the production cost of magnetized roasting, and it is difficult to meet the requirements of clean and green development of the steel industry, and achieve the effect of eliminating carbon emissions and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

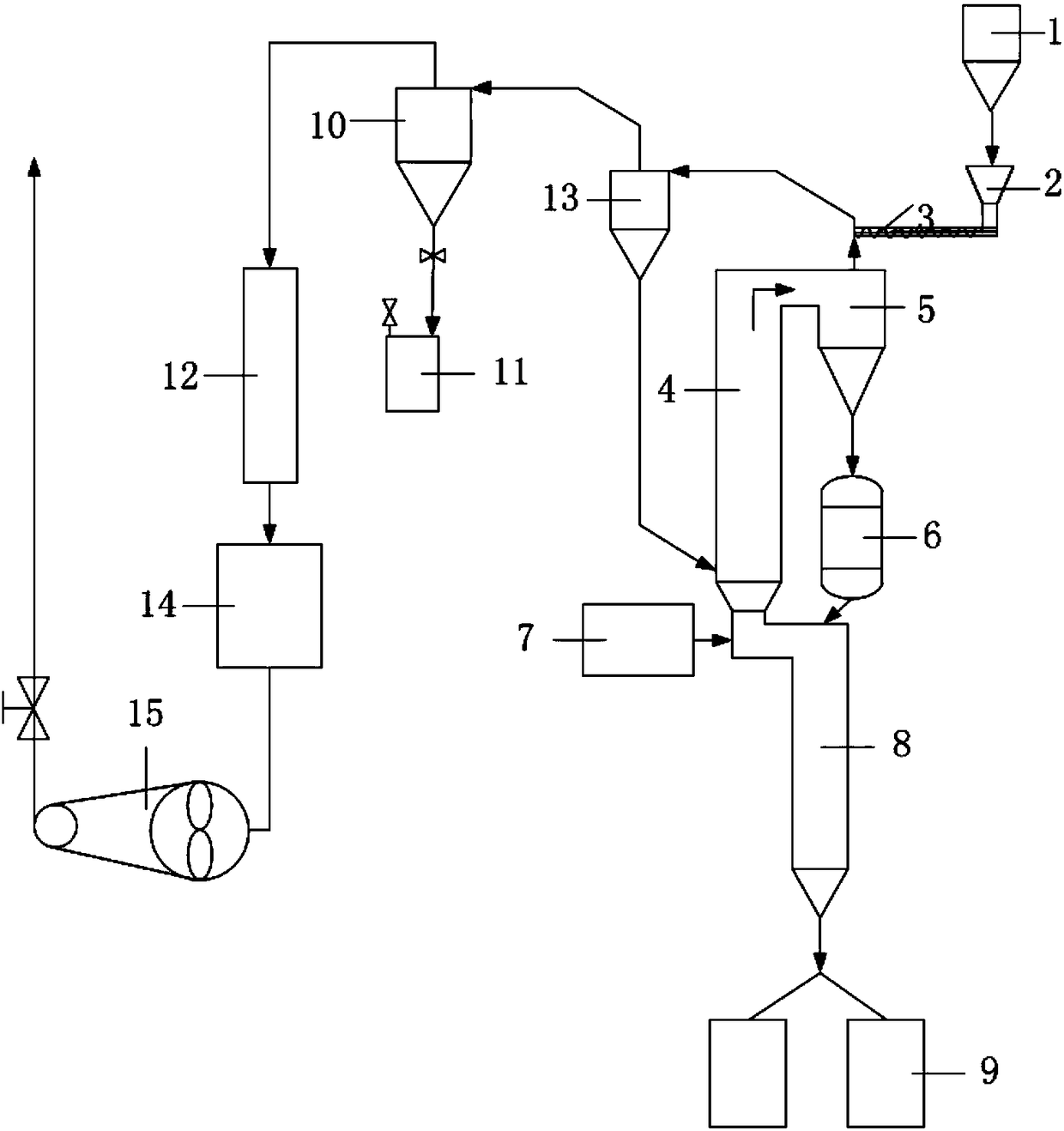

Method used

Image

Examples

Embodiment 1

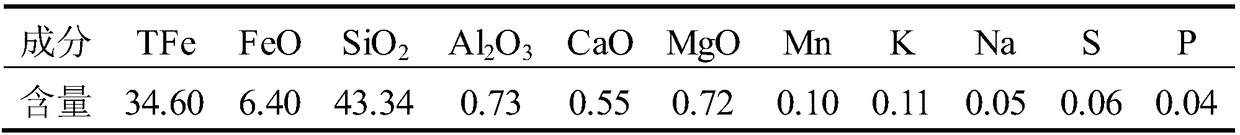

[0033] The ore sample used in this example is the iron ore in Donganshan, Anshan Iron and Steel Group. The results of chemical multi-element analysis of the ore are shown in Table 1, and the results of iron chemical phase analysis are shown in Table 2. It can be seen from the analysis results that the ore has a TFe grade of 34.60%, a FeO content of 6.40%, and the main impurity SiO 2 The content is 43.34%, and the remaining impurities are all less than 1%. The main iron-containing minerals in this ore are hematite, limonite and magnetite, and their iron distribution ratios are 64.76% and 27.29%, among which the iron distribution ratio of siderite is 6.45%.

[0034] Table 1 Chemical multi-element analysis of iron ore in East Anshan (mass fraction, %)

[0035]

[0036] Table 2 Iron phase analysis of iron ore in East Anshan (mass fraction, %)

[0037]

[0038] The chemical composition analysis results of siderite ore are shown in Table 3, and the iron chemical phase analys...

Embodiment 2

[0051] The ore sample used in this embodiment is Jingtieshan Iron Mine in Jiuquan Iron and Steel Corporation. The results of chemical composition analysis of the ore are shown in Table 6, and the results of iron chemical phase analysis are shown in Table 7. From the analysis results, it can be seen that the TFe grade of Jingtieshan iron ore is 33.51%, the FeO content is 17.82%, and the main impurity is SiO 2 , MgO, Al 2 o 3 And CaO, the content of other impurity minerals is less than 1%. The actual ore mainly contains iron minerals hematite and siderite, and its iron distribution rate is 61.26% and 36.61%, and it also contains a small amount of magnetite, iron sulfide and iron silicide.

[0052] Table 6 Jingtieshan iron ore chemical composition analysis (mass percentage, %)

[0053]

[0054] Table 7 Jingtieshan iron ore iron chemical phase analysis (mass percentage, %)

[0055]

[0056] The results of chemical composition analysis of siderite ore are shown in Table 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com