Nitrogen fertilizer compound synergist and preparation method

A compound synergist and synergist technology, applied in the field of nitrogen fertilizer, can solve the problems of reducing fertilizer nitrogen utilization rate, increasing soil pH value, and easy leaching of nitrate nitrogen, so as to reduce the amount of fertilizer and prolong the period of fertilizer effect , the effect of promoting absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

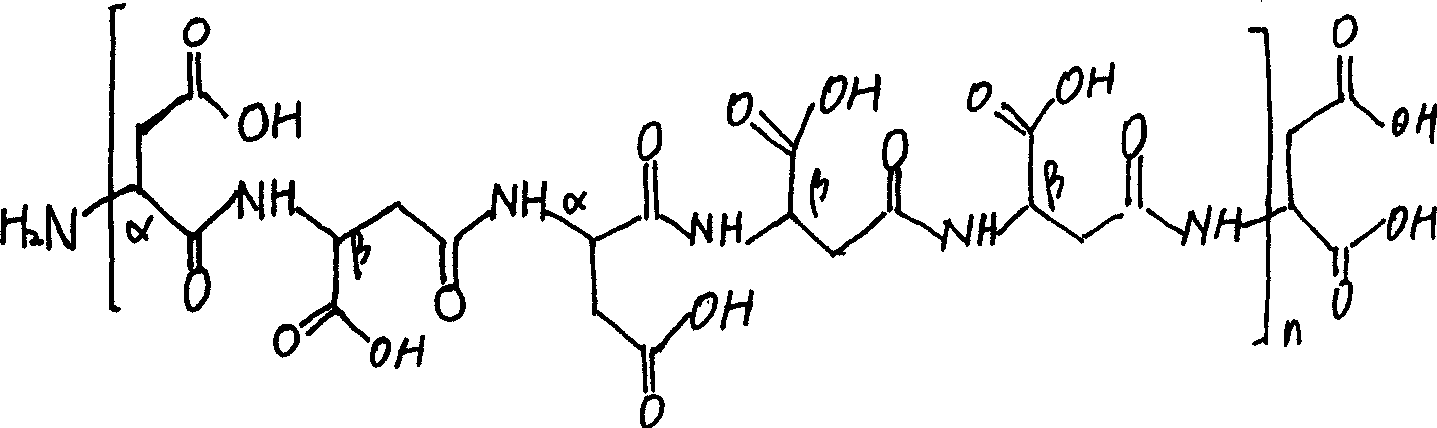

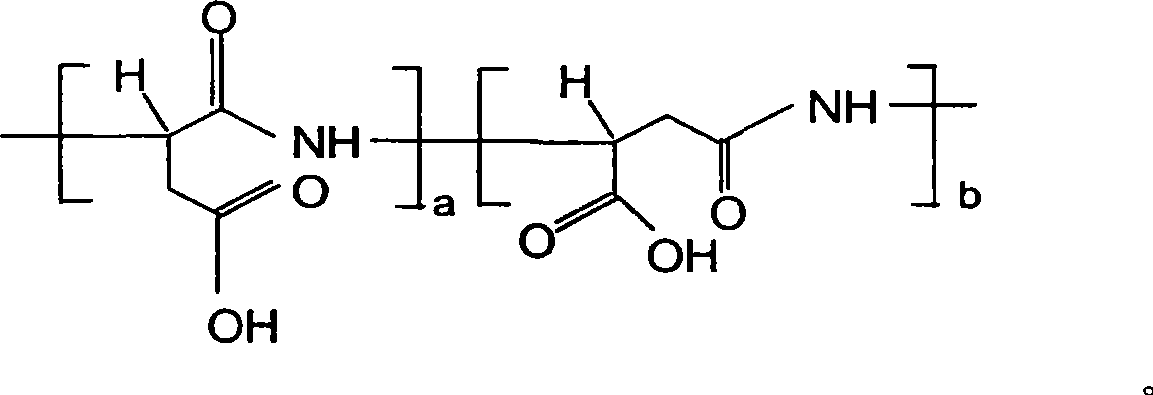

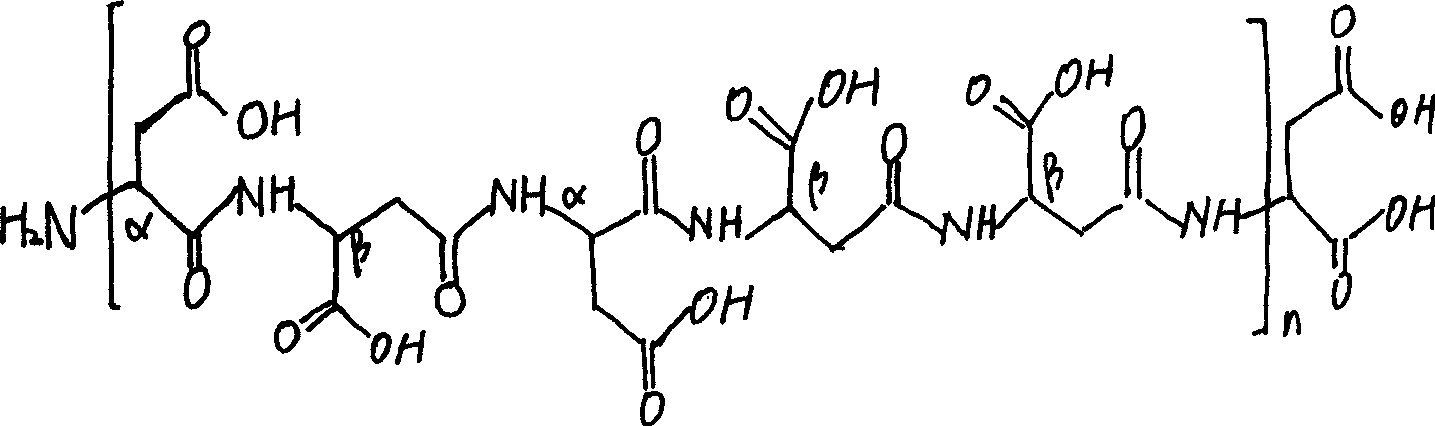

[0026] The raw materials of the nitrogen fertilizer compound synergist are: 0.25 parts of N-butylthiophosphoric triamide, 0.25 parts of dicyandiamide, 0.05 parts of PASP, 0.005 parts of alginic acid, and 0.25 parts of humic acid. The molecular weight of the PASP is: 80000 1. Polyaspartic acid having a structural formula such as formula 1.

[0027] Preparation method: The above-mentioned raw materials N-butylthiophosphoric triamide, dicyandiamide, PASP, alginic acid and humic acid are pulverized to 30 meshes, mixed and stirred evenly to prepare the nitrogen fertilizer compound synergist.

[0028] Slow / controlled release nitrogen fertilizer can be produced by using the prepared nitrogen fertilizer compound synergist.

Embodiment 2

[0030] The raw materials of nitrogen fertilizer compound synergist are: 0.5 part of thiophosphoric triamide, 0.5 part of 3,4-dimethylpyrazole phosphate, 0.8 part of PASP, 0.01 part of hydrolyzed amino acid, 0.5 part of humic acid, 0.001 part of molybdic acid Sodium, 0.001 part of manganese sulfate, the molecular weight of the PASP is: 200,000, polyaspartic acid with the structural formula as formula 1.

[0031] Preparation method: Grind the above raw materials phosphorothioate triamide, 3,4-dimethylpyrazole phosphate, PASP, hydrolyzed amino acid, humic acid, sodium molybdate, and manganese sulfate through 50 meshes, and mix and stir evenly to prepare Nitrogen fertilizer compound synergist.

Embodiment 3

[0033] The raw materials of nitrogen fertilizer compound synergist are: 0.9 part of phenylphosphoric diamide, 0.1 part of 3,5-dimethylpyrazole, 0.05 part of PASP, 0.05 part of fulvic acid, 0.5 part of fly ash (fly ash It is a mixture that contains a wide variety of substances, with the highest silicon content, followed by aluminum, in the form of complex double salts. Its main chemical components are silicon dioxide, aluminum oxide, iron oxide, calcium oxide and sulfur trioxide , magnesium oxide, sodium oxide, potassium oxide, etc., while fly ash can also be replaced by lignite or weathered coal.), 0.01 part of ammonium molybdate, 0.01 part of zinc sulfate, the PASP molecular weight is: the molecular weight is: 6001, structural formula Such as polyaspartic acid of formula 1.

[0034] Preparation method: crush the above raw materials phenylphosphoramide, 3,5-dimethylpyrazole, PASP, fulvic acid, fly ash, ammonium molybdate, and zinc sulfate through 80 meshes, mix and stir evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com