Special high-efficiency stable green ammonium nitrogen fertilizer for black soil and preparation method thereof

A technology of ammonium nitrogen fertilizer and stability, which is applied to the field of high-efficiency and stable green ammonium nitrogen fertilizer and preparation of black soil, can solve the problems of greatly different effects and unstable stable fertilizers, and achieves the improvement of potassium absorption rate and improved absorption. Utilization effect, effect of promoting crop growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

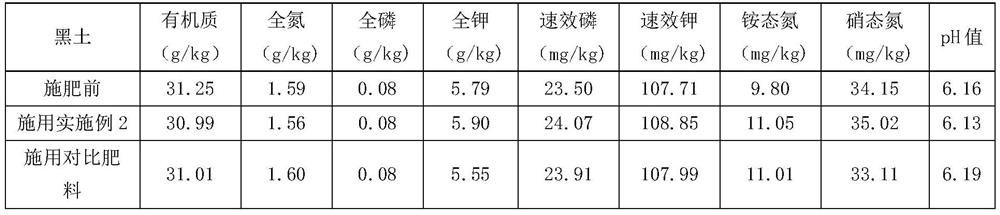

Embodiment 1

[0028] Use agricultural ammonium chloride as nitrogen source to prepare high-efficiency and stable green ammonium nitrogen fertilizer. Wet powder.

[0029] Preparation:

[0030] 1) Preparation of suspension solution: Dissolve 1 part of CP(2-chloro-6(trichloromethyl)-pyridine wettable powder into 200ml aqueous solution, stir evenly to make suspension solution, and set aside.

[0031] 2) Utilize the fluidized bed coating technology, place the prepared suspension solution in the fluidized bed liquid tank, and simultaneously inject 100 parts of ammonium chloride particles containing 26% nitrogen into the spray tower from the fertilizer feed port for fluidization Then with the operation of the fluidized bed, the suspension solution is uniformly coated on the surface of the ammonium chloride particles by the atomizing nozzle through the flow controller, and finally a high-efficiency and stable green ammonium nitrogen fertilizer containing 25% nitrogen is obtained. The operating pa...

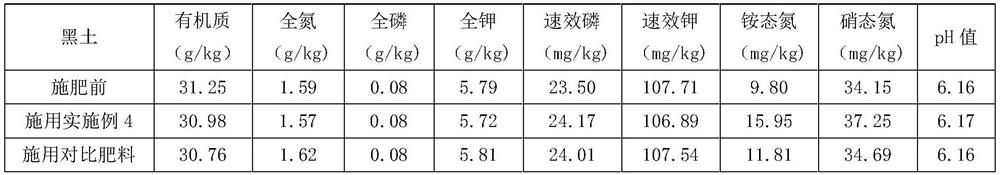

Embodiment 2

[0033] Use agricultural ammonium sulfate as nitrogen source to prepare high-efficiency and stable green ammonium nitrogen fertilizer. ; Ammonium sulfate powder contains 20.5% nitrogen.

[0034] Preparation:

[0035] Inject 100 parts of ammonium sulfate powder containing 20.5% nitrogen into the fertilizer mixing tank from the fertilizer inlet, and then sprinkle 1 part of CP (2-chloro-6 (trichloromethyl)-pyridine in the fertilizer mixing tank, Start the agitator to stir, when the ammonium sulfate and CP are evenly stirred (about 15 minutes), lift them to the feed inlet of the extruder through the bucket elevator, and carry out extrusion granulation to obtain nitrogen-containing granules with a particle size of 2.5-4.8mm 20% high-efficiency and stable green ammonium nitrogen granular nitrogen fertilizer.

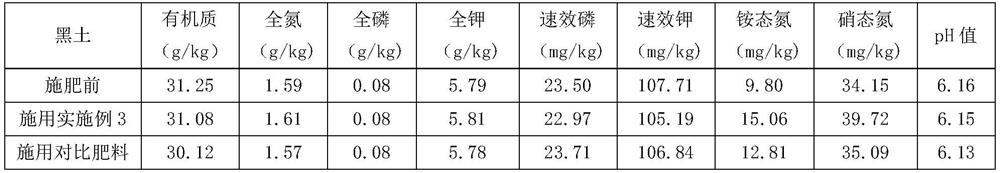

Embodiment 3

[0037]Use ammonium sulfate as nitrogen source to prepare high-efficiency and stable green ammonium nitrogen fertilizer. The raw materials are: based on 100 parts of ammonium sulfate powder, 1 part of CP (2-chloro-6 (trichloromethyl)-pyridine and DMPP (3,4-dimethylpyrazole phosphate) mixture, the ratio of the mixture is 1:1 by mass and number; wherein the ammonium sulfate powder contains 20.5% nitrogen.

[0038] Preparation:

[0039] 1) Prepare a mixed nitrification inhibitor: mix 1 part of CP (2-chloro-6 (trichloromethyl)-pyridine) with 1 part of DMPP (3,4-dimethylpyrazole phosphate), stir, and stir well for later use.

[0040] 2) Add 100 parts of ammonium sulfate powder containing 20.5% nitrogen into the fertilizer mixing tank, add the prepared mixed nitrification inhibitor into the fertilizer mixing tank, mix with the ammonium sulfate powder, and stir, and stir evenly , through the bucket elevator to the feed inlet of the extruder, extruding and granulating to produce a hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com