Zinc smelting technology

A zinc smelting and process technology, applied in the field of new zinc smelting technology, can solve the problems of slow sedimentation and sedimentation, difficult comprehensive utilization, difficult acid balance, etc., and achieves the effect of improving resource utilization rate, favorable for comprehensive utilization, and favorable for comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

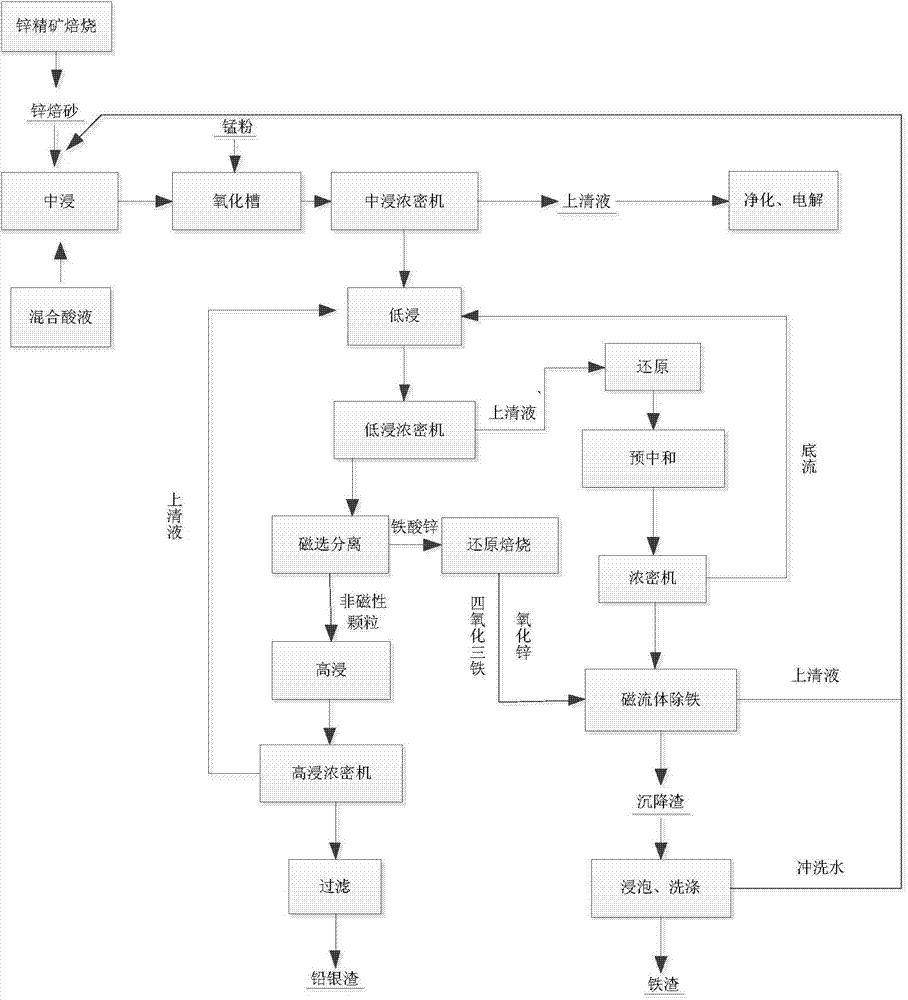

[0035] see figure 1 , the high iron sphalerite concentrate is roasted so that ZnS is oxidized to ZnO as much as possible, and at the same time, the impurities of lead, cadmium and arsenic are oxidized and transformed into volatile compounds to be separated from the concentrate. The roasting temperature is controlled at 870°C, and the air excess coefficient is 1.20; Put the zinc calcine in the stirring tank and add acid solution to make slurry, keep the temperature at 65 °C, add the zinc oxide-containing material or calcine into the dipping stirring tank according to the liquid-solid ratio of 7:1, and the reaction time is 1.5h , the acid concentration at the beginning of medium leaching is 20g / L, and the final pH is 5.1; after neutral leaching and low leaching of zinc calcine, the obtained leaching slag still contains high zinc content, and the zinc grade is 22%. Low acid leaching is carried out in the low leaching tank to dissolve insoluble zinc oxide. The low temperature and ...

Embodiment 2

[0044] see figure 1 , the high-iron sphalerite concentrate is roasted so that ZnS is oxidized to ZnO as much as possible, and at the same time, the impurities of lead, cadmium and arsenic are oxidized and transformed into volatile compounds to be separated from the concentrate. The roasting temperature is controlled at 880 ° C, and the air excess coefficient is 1.25; Put the zinc calcine in the mixing tank and add acid solution to make slurry, keep the temperature at 75 °C, add the zinc oxide-containing material or calcine into the dipping mixing tank at a liquid-solid ratio of 8:1, and the reaction time is 2 hours. The initial acid concentration of intermediate leaching is 40g / L, and the final pH is 5.2; after neutral leaching and low leaching, the leaching slag obtained still has a high zinc content, and the zinc grade is 22%. The leaching tank is used for low-acid leaching to dissolve insoluble zinc oxide. The low-temperature low-acid leaching process is carried out accordi...

Embodiment 3

[0053] see figure 1 , the high-iron sphalerite concentrate is roasted so that ZnS is oxidized to ZnO as much as possible, and at the same time, the impurities of lead, cadmium and arsenic are oxidized and transformed into volatile compounds to be separated from the concentrate. The roasting temperature is controlled at 900 ° C, and the air excess coefficient is 1.30; put the zinc calcine in the stirring tank and add acid solution to make slurry, keep the temperature at 85 °C, add the zinc oxide-containing material or calcine into the dipping stirring tank at a liquid-solid ratio of 9:1, and the reaction time is 2 hours. The initial acid concentration of intermediate leaching is 60g / L, and the final pH is 5.4; after neutral leaching and low leaching, the obtained leaching slag still contains high zinc content, and the zinc grade is 22%. The leaching tank is used for low-acid leaching to dissolve insoluble zinc oxide. The low-temperature low-acid leaching process is carried out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com