Beneficiation method of low-grade ilmenite

A beneficiation method and technology for low-grade titanium, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the disadvantages of flotation, high cost of flotation reagents, inability to achieve economical and efficient utilization of low-grade titanium resources, etc. problems, to achieve the effect of reducing the content and improving the grade of ore feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. It should be noted that, in this specification, unless otherwise specified, the percentages involved refer to percentages by weight, which will not be repeated hereafter.

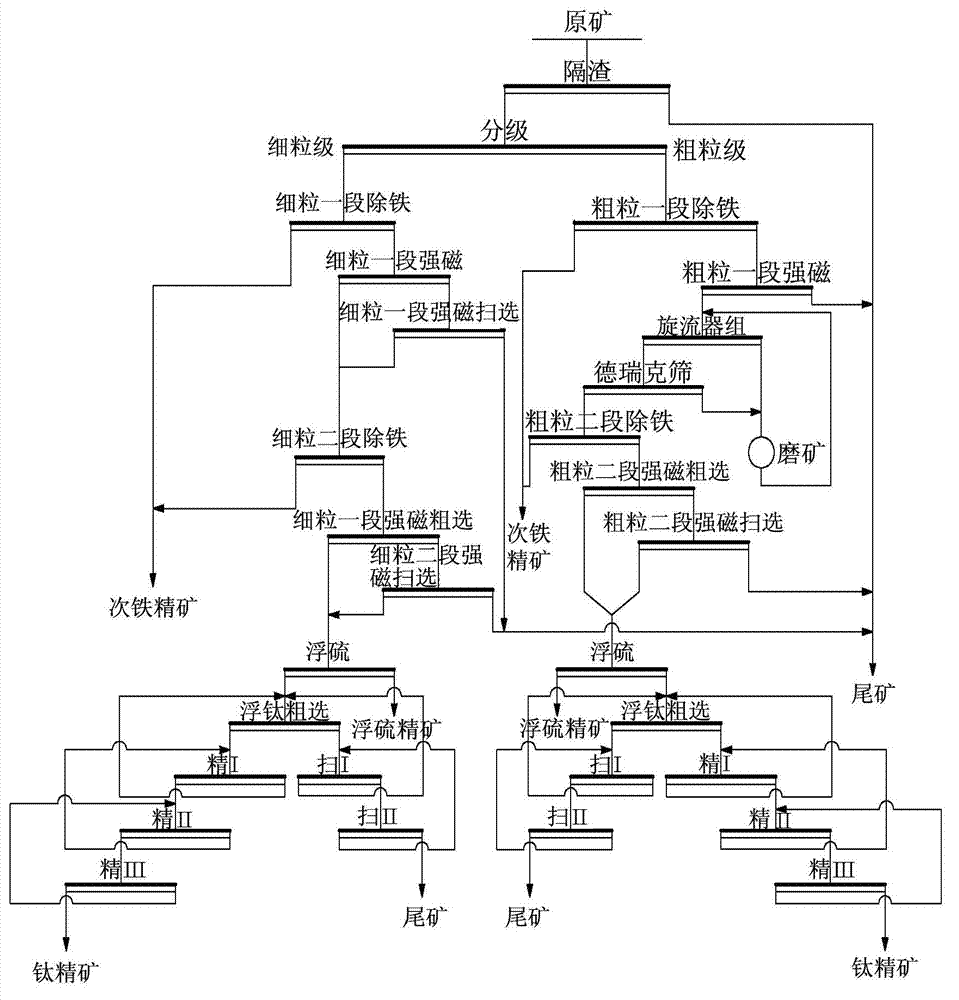

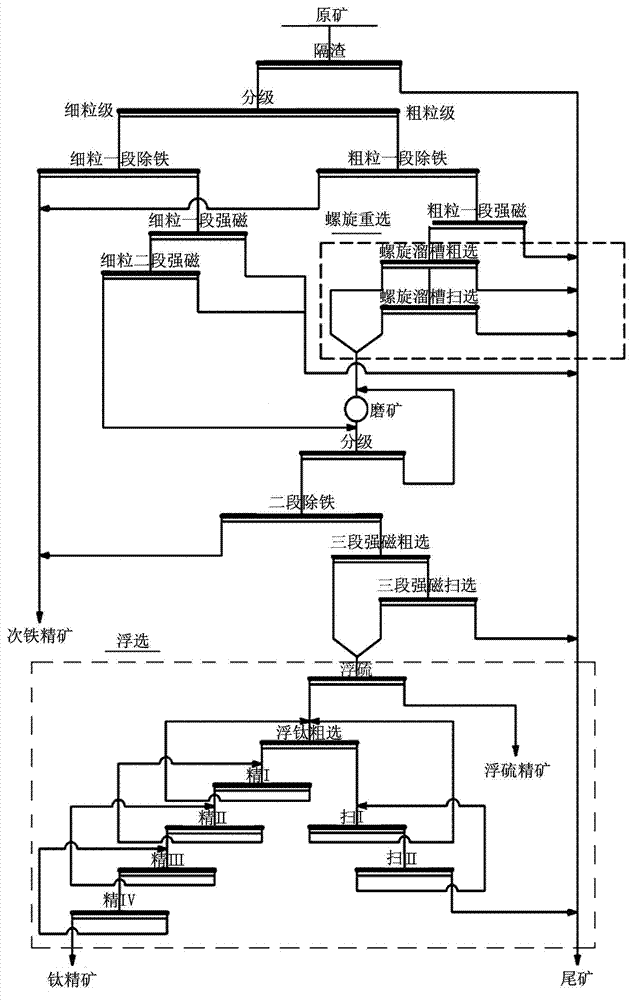

[0018] figure 1 It is the flow chart of the original beneficiation process of ilmenite, figure 2 It is the flow chart of the beneficiation process of ilmenite of the present invention.

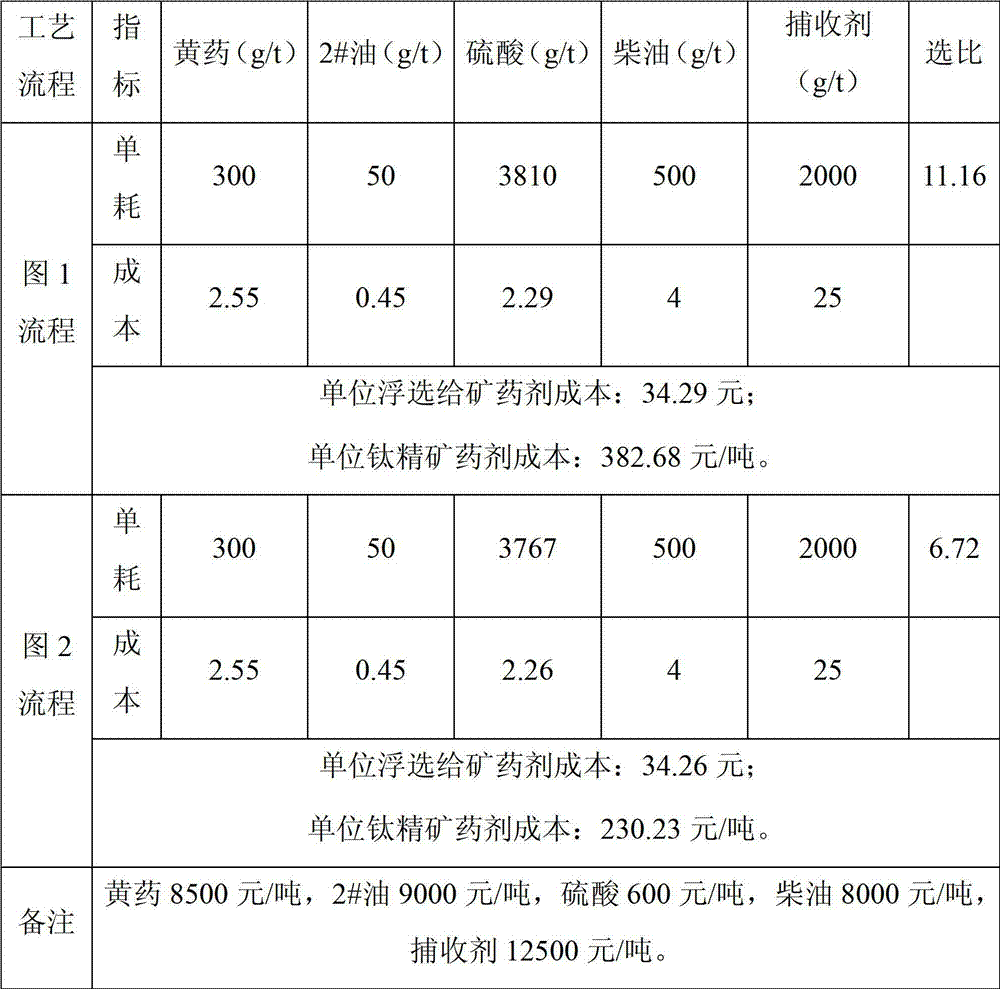

[0019] like figure 1 As shown, the original beneficiation process is to classify the raw ore after slag separation treatment to obtain coarse-grained materials and fine-grained materials. Secondary iron concentrate; Among them, the coarse-grained iron-removing tailings and the fine-grained iron-removing tailings are subjected to two stages of strong magnetic separation and then flotation to obtain the final titanium concentrate. use figure 1 The process flow shown is for low-grade (TiO 2 content is abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com